Material temperature control method of sinter-circle-cooling machine

A technology of sintering ring cooler and material temperature, which is applied in the direction of furnace control device, treatment of discharged materials, furnace, etc., which can solve the problems of insufficient utilization of hot waste gas, failure of ring cooling to achieve cooling effect, and reduced production efficiency, etc. , to avoid equipment loss and casualties, improve sinter quality, and reduce production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

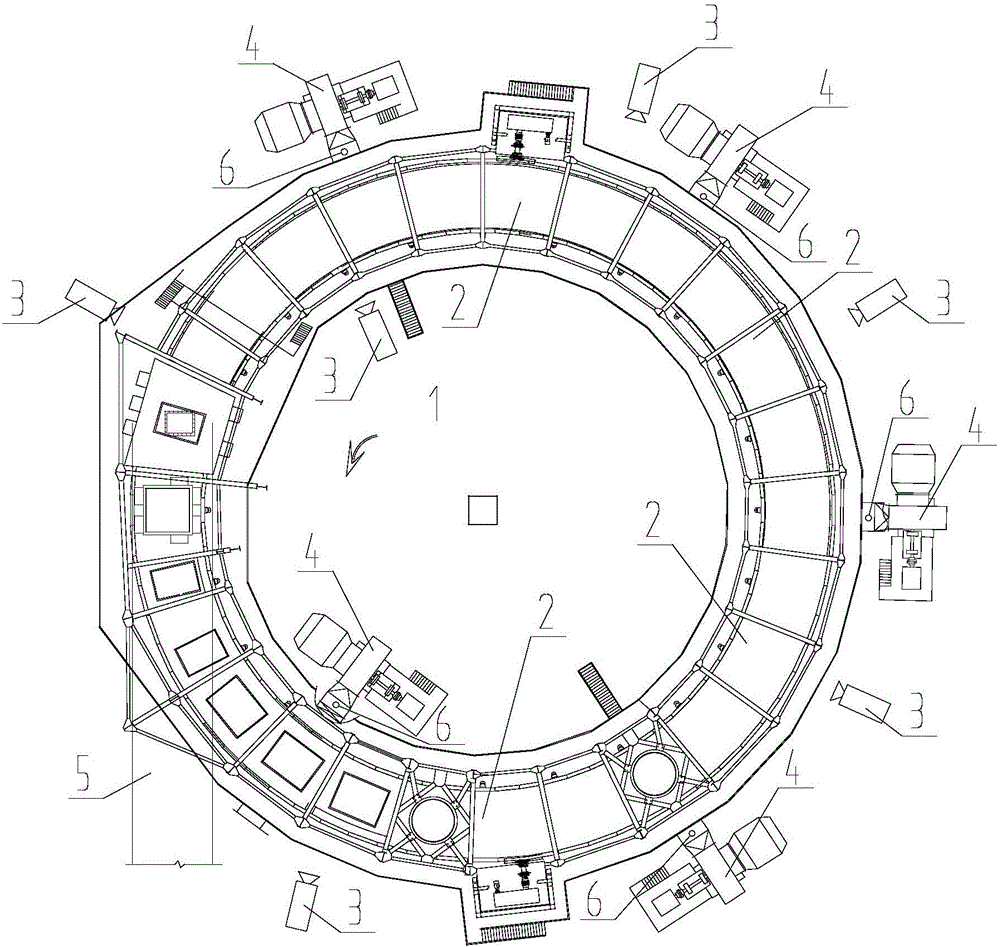

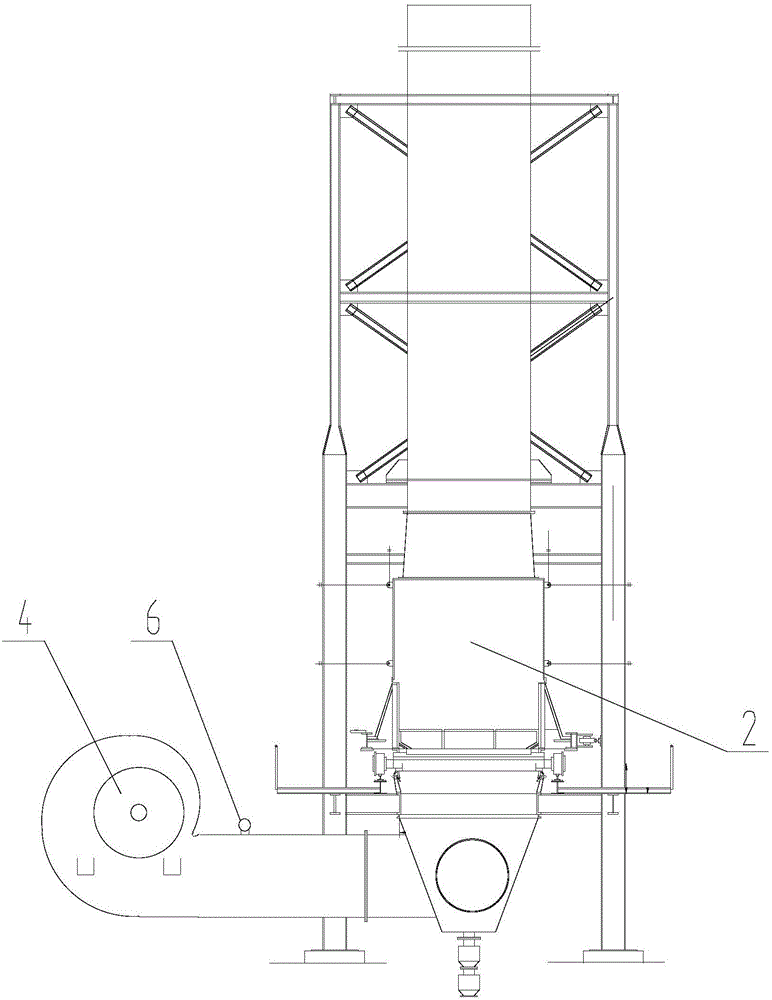

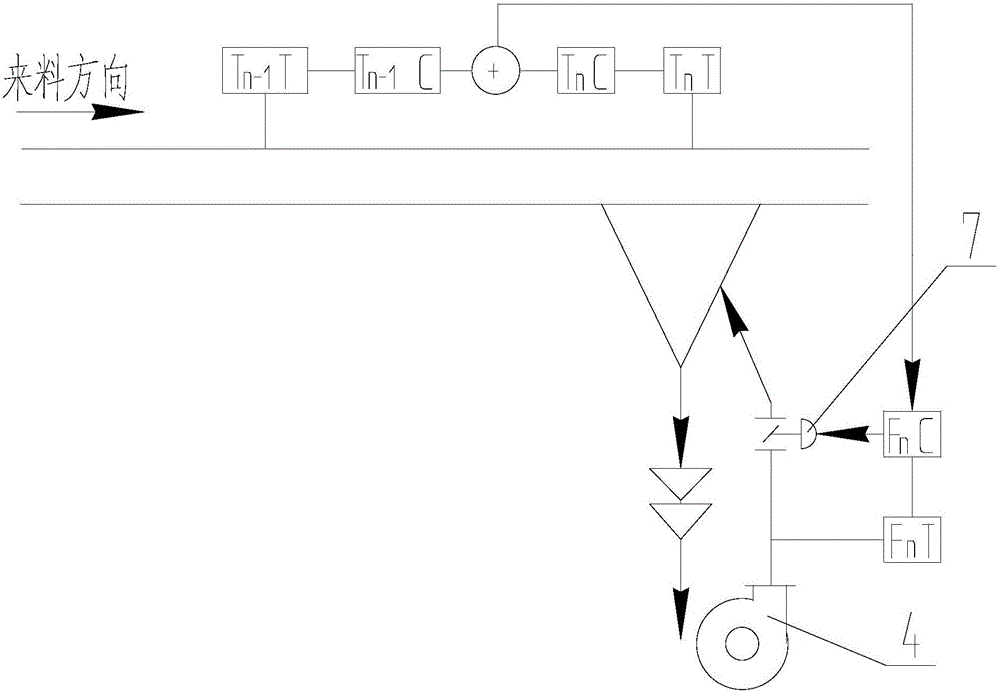

[0032] Such as figure 1 , figure 2 As shown, a method for controlling the material temperature of a sintering ring cooler comprises the following steps:

[0033] Step 1: First, configure a suitable non-contact temperature measuring device 3 according to the measured temperature and the operating conditions of the equipment. The temperature measuring device 3 itself should be resistant to high temperature; then, install a mounting bracket on the side of the ring cooler 1 to install the temperature measuring device 3. The installation height and angle of the temperature measuring device 3 on the mounting bracket should be adjustable, so as to achieve the purpose of keeping the equipment away from the heat source without affecting the measurement; then, through the non-contact Type temperature measuring device 3, which measures the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com