Sliding plate arc surface rotor pump

A technology of rotor pump and slide plate, which is applied in the field of slide plate arc rotor pump, high viscosity, even the delivery of adsorbed fluid, and fluid delivery pump, which can solve the problem of trapped oil and other problems, achieve small difficulty, avoid the phenomenon of trapped oil, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

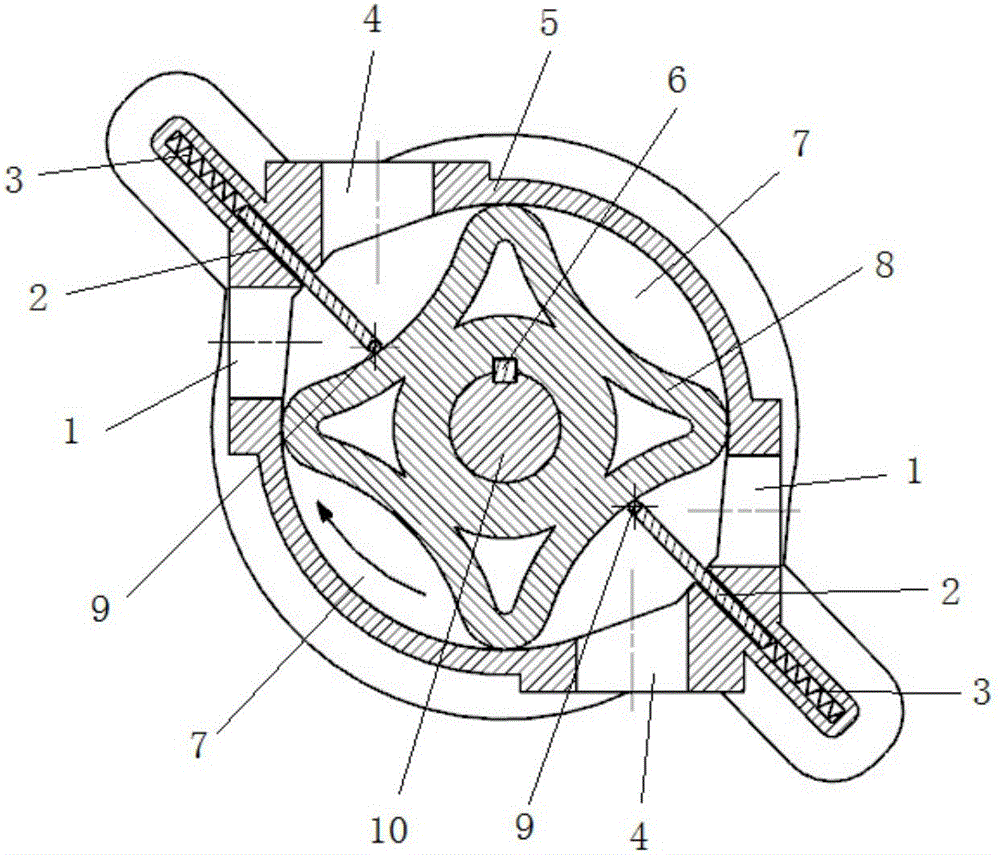

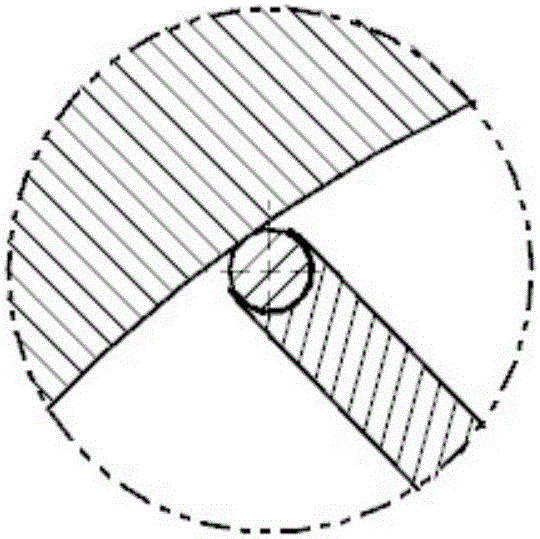

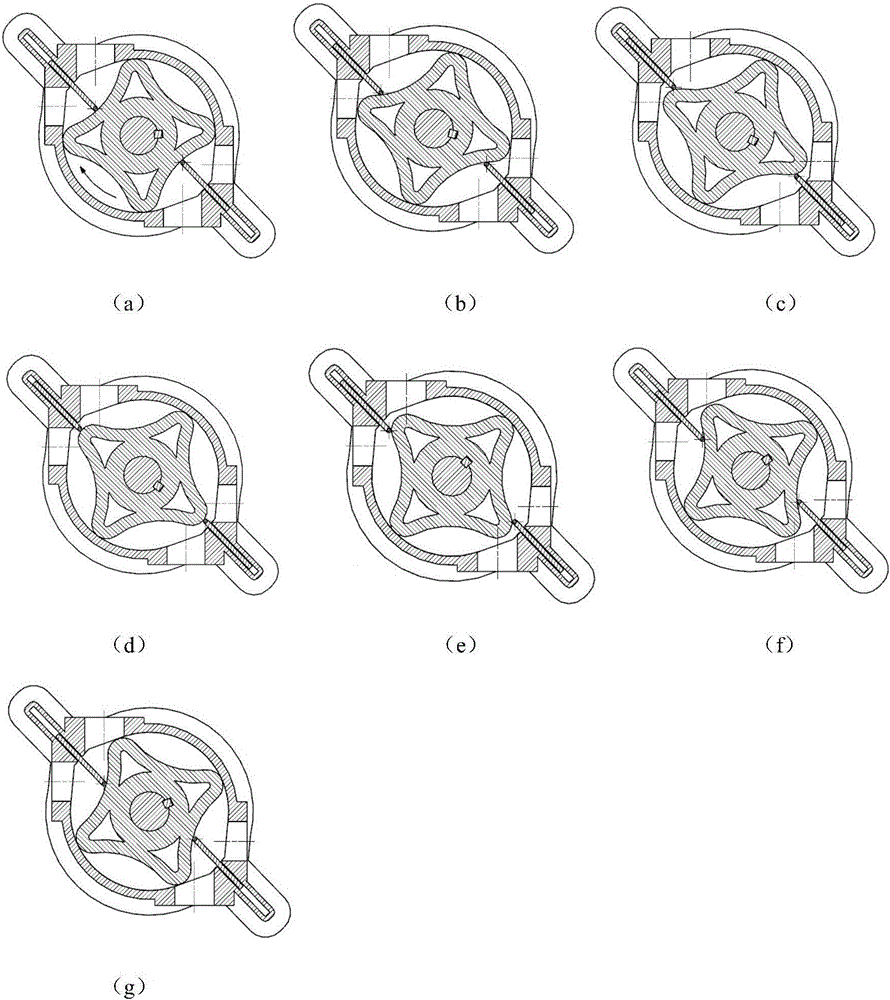

[0014] Refer to attached figure 1 , a skateboard arcuate rotor pump, including a pump body 5 with two slide slots along the axial direction, an arcuate rotor 8, a shaft 10, a key 6, a slide plate 2, and a cylindrical roller 9. When working, the arc-shaped rotor 8 is driven by the key 6 and rotates with the shaft 10. Four chambers 7 are formed between the arc-shaped rotor 8 and the pump body 5. When the chambers 7 turn to meet the slide plate 2, the chambers The chamber is divided into a liquid discharge chamber (communicated with the liquid discharge port 1) and a liquid suction chamber (communicated with the liquid suction port 4) by the slide plate 2. Such as image 3 As shown, with the rotation of the arc-shaped rotor, the volume of the two liquid discharge chambers becomes smaller and smaller, causing the fluid to be squeezed out from the two liquid discharge ports 1, while the volume of the two liquid suction chambers becomes larger and larger, causing the fluid to be sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com