Stepless valve rocker mechanism with variable lift and corresponding valve device

A valve rocker arm and valve technology, applied in the direction of valve devices, valve lifts, mechanical equipment, etc., can solve the problems of large space occupied by the mechanism, continuous adjustment, and excessive power loss of friction pairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

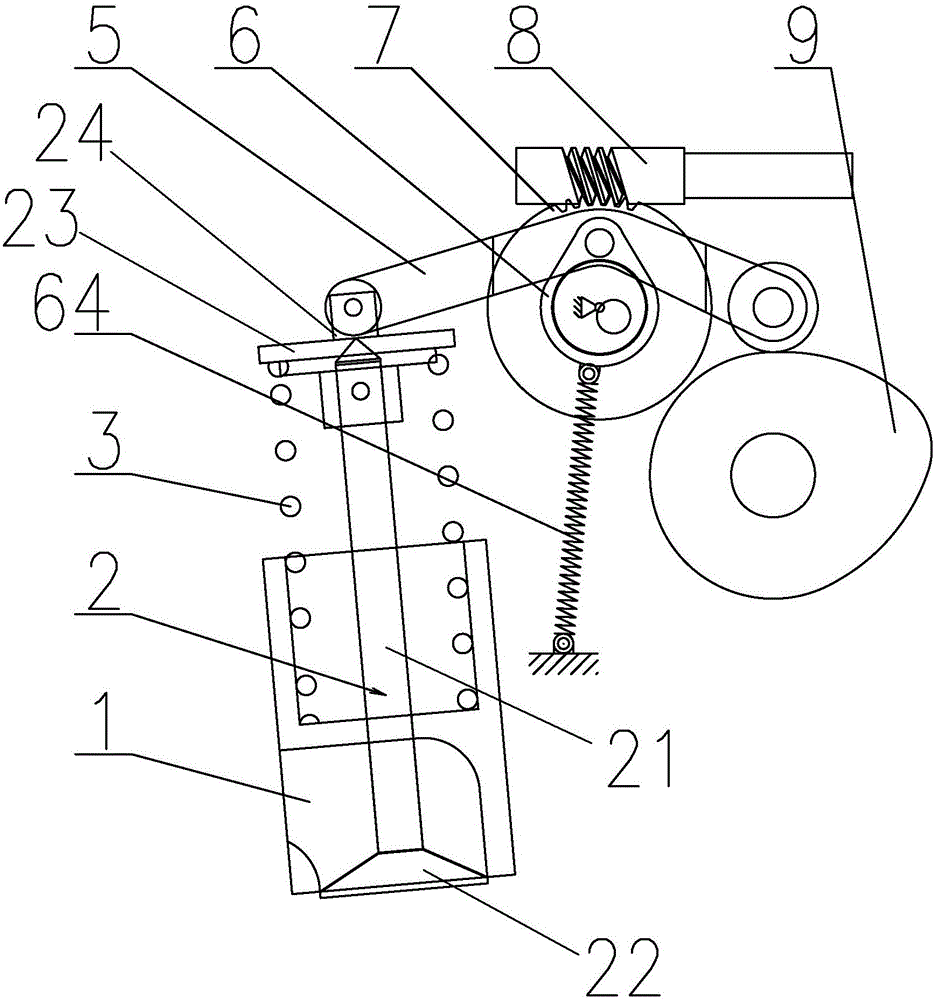

[0026] Such as figure 1 As shown, the valve rocker mechanism provided in this embodiment is used to cooperate with the valve rod of the valve device to control the size of the valve channel of the valve device. The whole valve device includes a valve seat 1, a valve rod 2, a valve rod spring 3, a valve Rocking arm 5, crank connecting rod 6, worm wheel 7, worm screw 8 and cam 9.

[0027] The lower part of the valve seat 1 is provided with a valve passage connecting the side wall and the bottom end, and the upper part of the valve seat 1 is provided with a spring groove, and the lower end of the spring groove communicates with the valve passage through a valve stem through hole. The valve stem 2 includes a stem portion 21, a plug 22, a spring top plate 23, and a rocker hinge block 24. The lower end of the stem portion 21 is fixedly connected to the plug 22, the upper end is fixedly connected to the spring top plate 23, and the middle part is passed through the valve stem of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com