Automatic drainage system of long tunnel reverse slope

A long tunnel and automatic drainage technology, applied in drainage, safety devices, mining equipment, etc., can solve the problems of smaller space and affect the entry and exit of large equipment, and achieve the effect of increasing the passage space of vehicles and machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

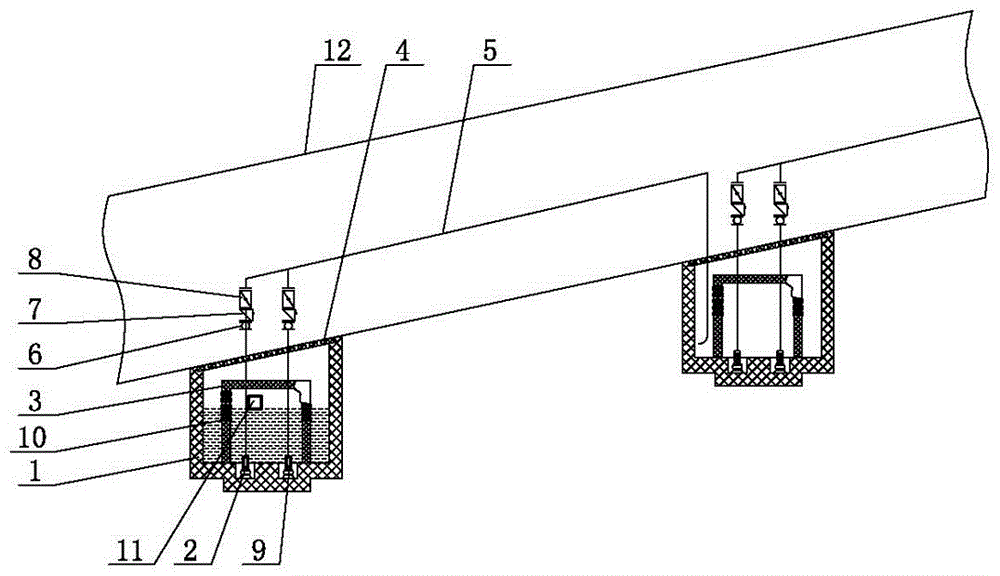

[0009] The anti-slope automatic drainage system for long tunnels, such as figure 1 As shown, it includes several water collection wells 1 arranged along the length direction of the tunnel 12, the water collection wells 1 are all set at the bottom of the tunnel 12, and the upper part of each water collection well 1 is provided with a well cover 4, and several through holes are provided on the well cover 4, and the well cover 4 can be closed On the upper part of the water collection well 1, a water filter box 3 is arranged in the water collection well 1, and several filter holes 10 are provided on the upper part of the side wall of the water filter box 3, and a water level measuring device, a first water pump 2 and one end of the drain pipe 5 are arranged in the water filter box 3, and the water level is measured. The device is connected with the first water pump 2, and the first water pump 2 is connected with the drain pipe 5, and the other end of the drain pipe 5 is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com