Coupling detection device during downhole tubing tripping

A detection device and tubing technology, which is used in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems of inability to achieve accurate and timely feedback of electrical signals, unresolved, slow response, etc., to meet the requirements of pressure-bearing operations, The effect of ingenious structure design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

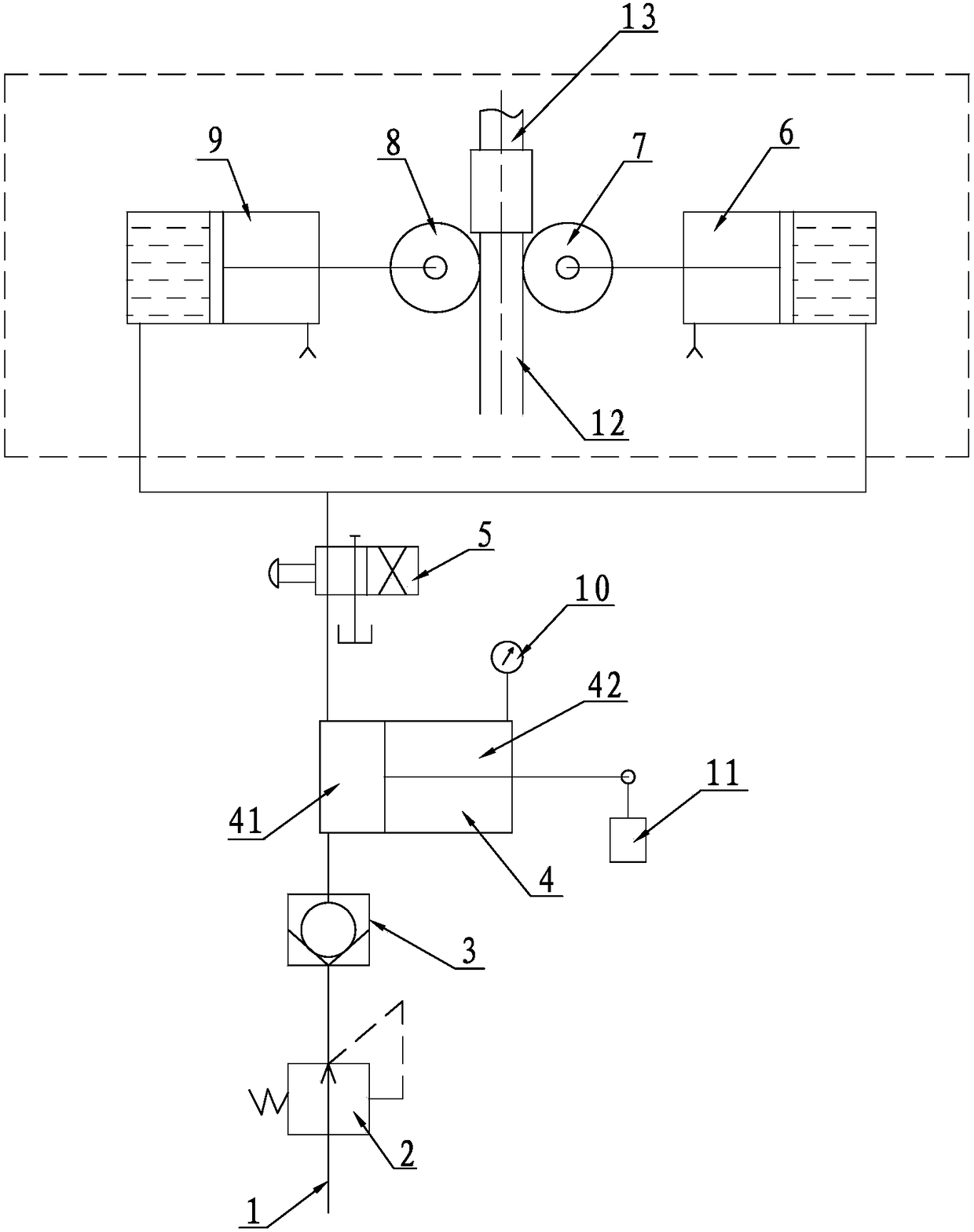

[0013] A coupling detection device during downhole tubing tripping, such as figure 1 As shown, it includes pressure oil oil pipe 1, pressure regulating valve 2, one-way valve 3, variable diameter signal detection valve 4, steering valve 5, right oil cylinder 6, right roller 7, left roller 8, left oil cylinder 9, air pressure gauge 10, Prompting device travel switch 11, oil pipe 12 and collar 13, right roller 7 is installed on the outer end of the piston rod of right oil cylinder 6, left roller 8 is installed on the outer end of the piston rod of left oil cylinder 9, oil pipe 12 and collar 13 The combination assembly is vertically arranged in the oil well, and the right roller 7 and the left roller 8 are symmetrically arranged on both sides of the combination assembly of the oil pipe 12 and the coupling 13, and the right roller 7 and the left roller 8 are connected with the oil pipe 12 or the coupling 13 respectively. The side walls are in close contact with each other. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com