Novel active hydraulic control packer

A packer and hydraulic control technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of complex structure, inability to be reused repeatedly, poor modularization, etc., and meet the structural requirements Effects of compactness, shortened working time, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

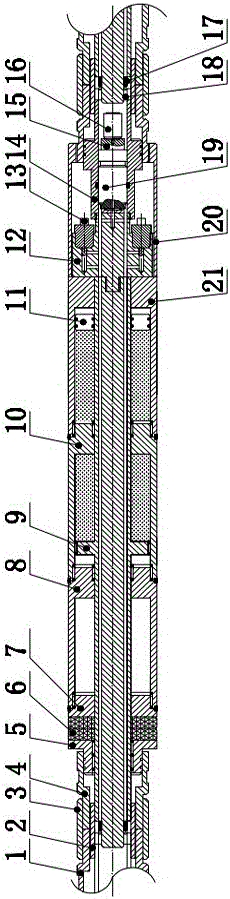

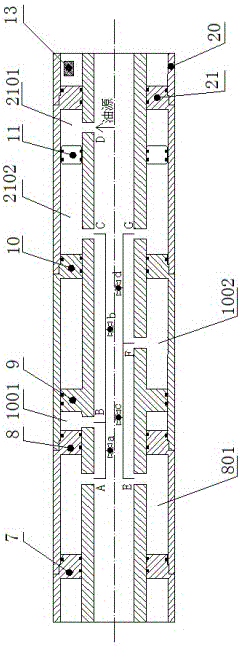

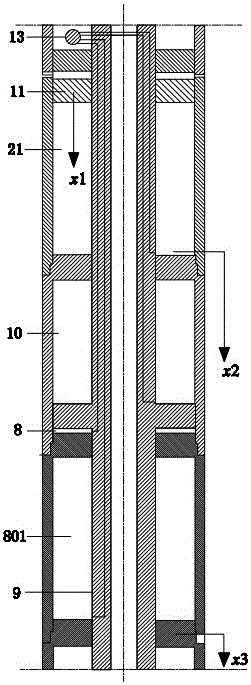

[0031] Such as figure 1 and figure 2 As shown, a new type of active hydraulic control packer includes a fixed mandrel 9, on which an upper joint 1 and a lower joint 4 are sheathed, one end of the upper joint 1 and one end of the lower joint 4 are in close contact and the upper The outer side of the joint 1 and the lower joint 4 is threaded through the sleeve ring 3, and the inner side of the upper joint 1 and the lower joint 4 is threaded with the mandrel 9 through the balance sleeve 2; the mandrel 9 is also provided with a connecting block 5, the connecting block One end of 5 is threadedly connected with the other end of lower joint 4, and connecting block 5 is threadedly connected with mandrel 9.

[0032] The mandrel 9 is also sequentially provided with a push hydraulic cylinder 8 , an action hydraulic cylinder 10 and a power hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com