Aluminum plastic reinforced type mullion structure

A medium-strength structure and reinforced technology, applied in the direction of the wing fan frame, etc., can solve the problems of affecting the lighting and ventilation performance of doors and windows, affecting the performance and quality of doors and windows, and destroying aesthetics, so as to improve the safety level and wind pressure resistance level of doors and windows. , Simple structure, increase the effect of wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

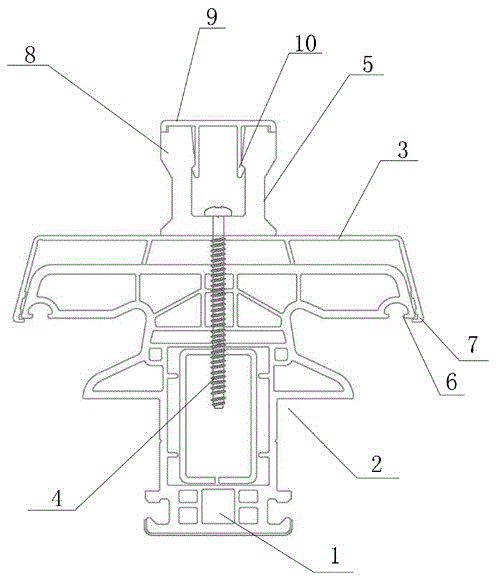

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a kind of aluminum-plastic-reinforced mid-strut structure according to the present invention comprises a mid-strut profile bar 1 whose two ends are horizontally connected in the middle of the mullions on both sides of the building doors and windows, and the entire doors and windows are divided up and down and strengthened. The upper and lower sides of the mid-stiff profile bar 1 are respectively provided with L-shaped glass insert grooves 2 for fixing glass, and the outdoor side of the mid-stiff profile bar 1 is connected with a strip-shaped aluminum alloy profile plate 3 by snap-fitting. On the outer surface of the aluminum alloy profile plate 3 is connected an outwardly protruding elongated central stiffening member 5 through a fastener 4 .

[0010] As shown in the figure, the middle stiff section bar 1 is made of a polymer heat-insulating section, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com