Method for preparing supported palladium catalyst electrode on basis of graphene-doped Nafion film modification

A palladium catalyst and graphene technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as difficult to remove, mutagenic, and toxic, and achieve stability, simple operation, The effect of enhancing the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Put the 2cm×2cm titanium mesh into 0.3mol / L sodium carbonate solution to soak and remove oil, boil in 0.1mol / L oxalic acid solution for 30min to remove surface oxide, and then rinse with double distilled water Clean and dry with nitrogen gas for later use;

[0025] (2) Get graphene to disperse in the isopropanol solution that mass concentration is 0.2% Nafion, graphene mass concentration 0.04%, ultrasonic dispersion 30min, the Graphene-Nafion dispersion liquid that makes uniform dispersion is standby;

[0026] (3) adopt the hydrochloric acid solution 100ml that every 1g palladium chloride corresponds to add 3mol / L and correspondingly add water and dilute to obtain the palladium chloride solution of 4g / L;

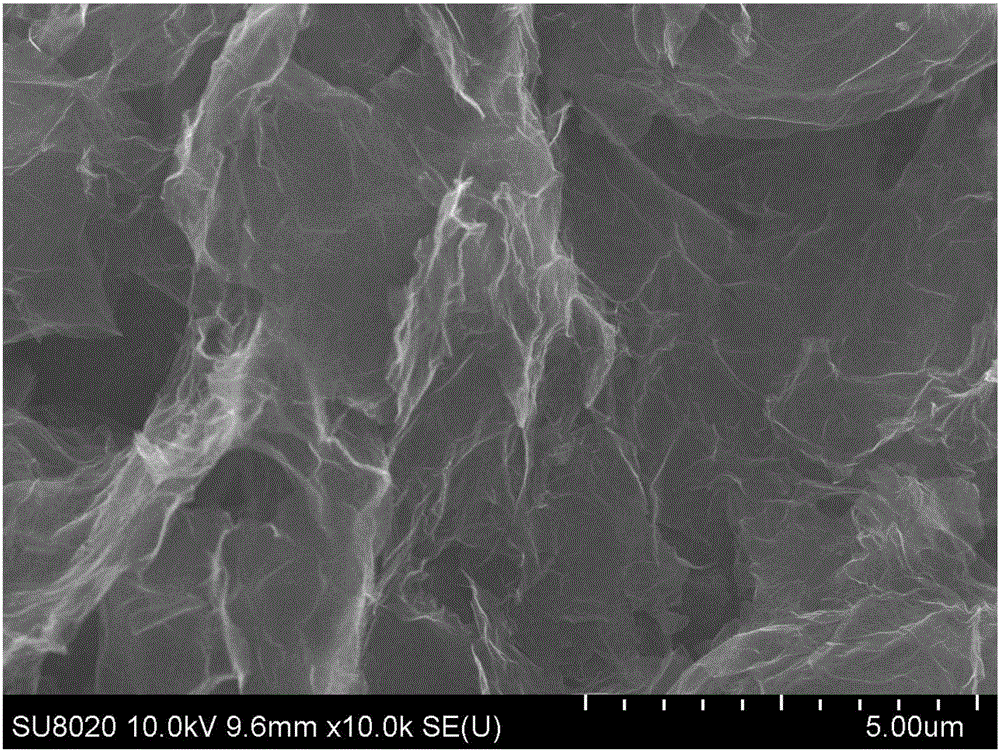

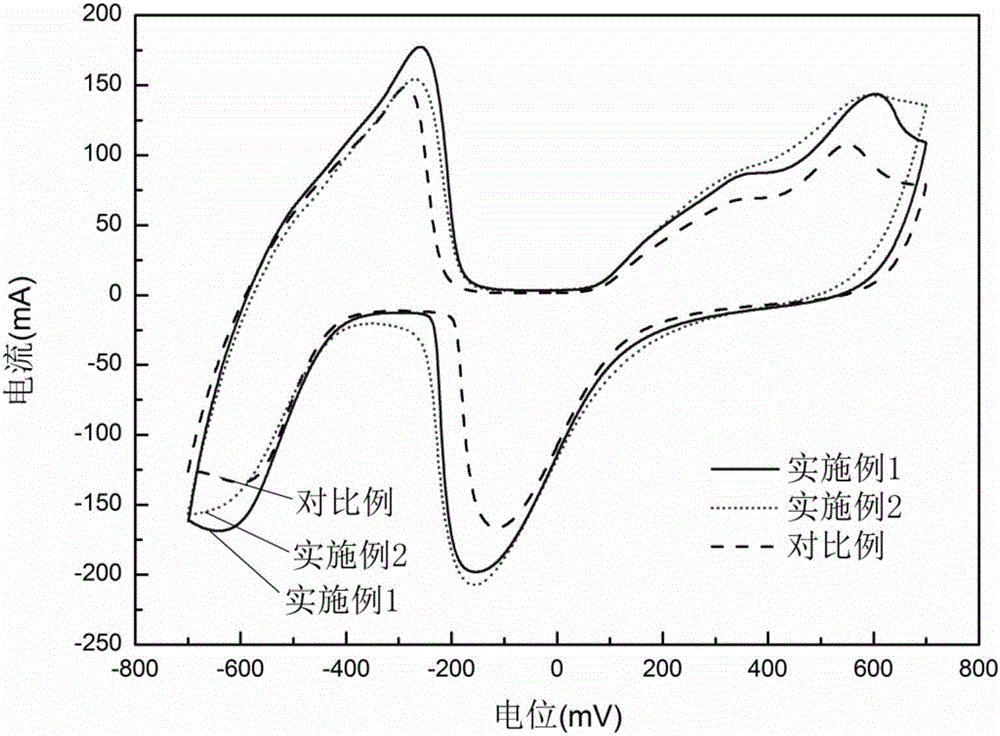

[0027] (4) Take 60 μL of the dispersion obtained in step (2), and evenly drop-coat it on the titanium mesh treated in step (1), and place it horizontally to dry naturally to prepare a Graphene-Nafion / Ti electrode. Depend on figure 1 It can be seen that graphene ...

Embodiment 2

[0031] (1) Put the 2cm×2cm titanium mesh into 0.3mol / L sodium carbonate solution to soak and remove oil, boil in 0.1mol / L oxalic acid solution for 30min to remove surface oxide, and then rinse with double distilled water Clean and dry with nitrogen gas for later use;

[0032] (2) Get graphene to disperse in the isopropanol solution that mass concentration is 0.2% Nafion, graphene mass concentration 0.06%, ultrasonic dispersion 30min, the Graphene-Nafion dispersion liquid that makes uniform dispersion is standby;

[0033] (3) adopt the hydrochloric acid solution 100ml that every 1g palladium chloride corresponds to add 3mol / L and correspondingly add water and dilute to obtain the palladium chloride solution of 4g / L;

[0034] (4) Take 60 μL of the dispersion obtained in step (2), and evenly drop-coat it on the titanium mesh treated in step (1), and place it horizontally to dry naturally to prepare a Graphene-Nafion / Ti electrode;

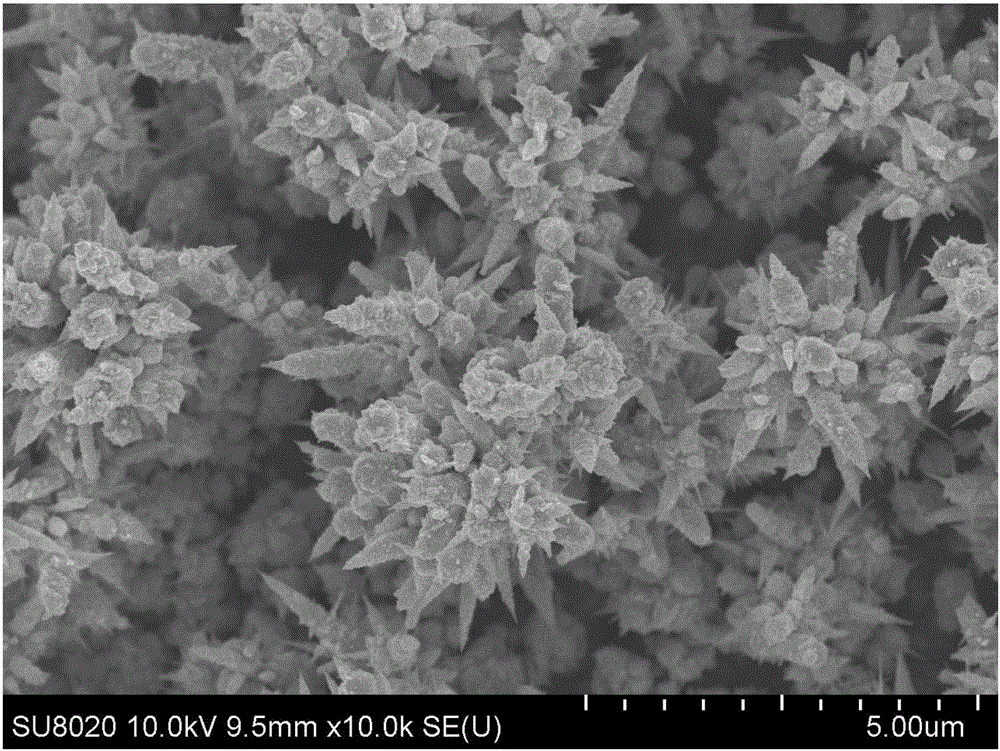

[0035] (5) The Graphene-Nafion / Ti electrode pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com