Winding molding method of all-composite material shells

A composite material and winding molding technology, which is applied in the field of winding molding of all-composite material shells, can solve the problems of complicated assembly and disassembly of core molds, large equipment operating inertia, and large central axis deflection, etc., to achieve simple and practical operation and Promote, reduce the difficulty of production operations, and the effect of low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

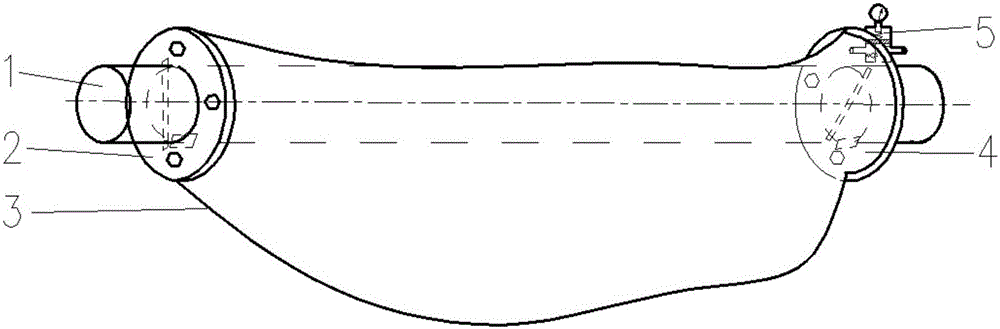

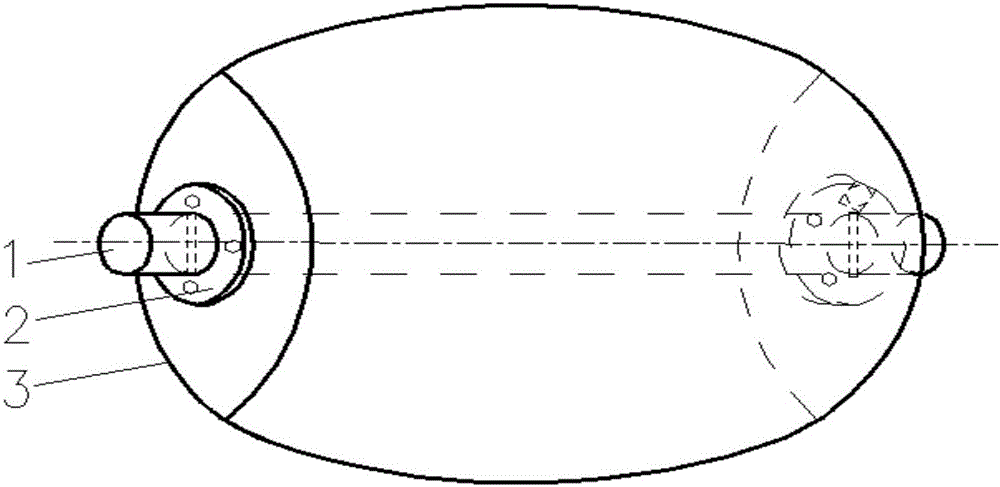

Embodiment 1

[0018] Example 1 According to the design requirements: preform a carbon fiber phenolic resin-based composite shell with an inner wall length of 2000mm, a diameter of 500mm, a head radius of 300mm, two head openings with a diameter of 300mm and 200mm, and a thickness of 10mm. The designed metal rotating shaft 1 has a length of 3000 mm, a diameter of 150 mm and a thickness of 10 mm. The airbag 3 is made of high-temperature-resistant silicon rubber airbag, which is filled with 0.5MPa nitrogen gas 6 and expands. The length of the outer wall is 2000mm, the diameter is 500mm, the radius of the head is 300mm, and the thickness is 5mm; the outer diameter of the positioning flange in the positioning part 2 is 200mm , the inner diameter is 150mm, and the thickness is 30mm; the outer diameter of the fixed flange in the fixed part 4 is 300mm, the inner diameter is 150mm, and the thickness is 20mm.

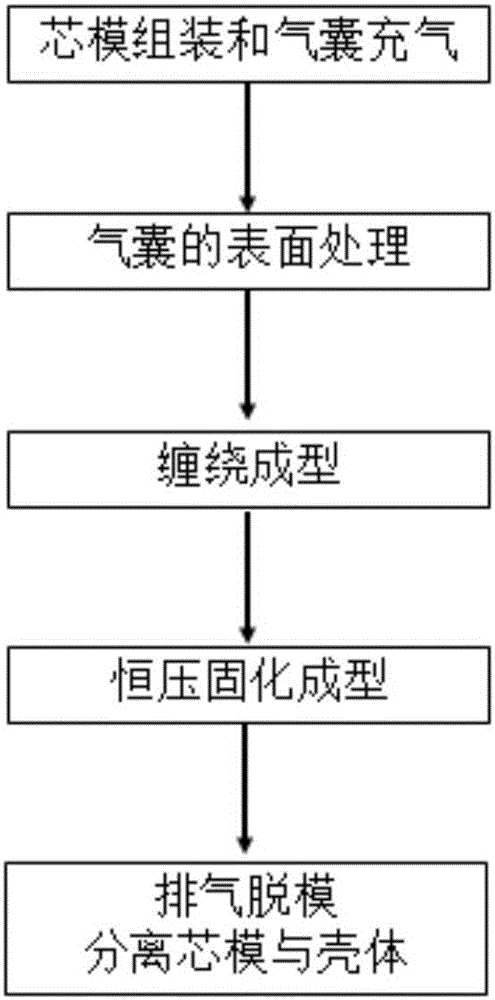

[0019] figure 1 It is a flow chart of the winding forming method of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com