Flow-type circulatory burdening squeezing granulator

A flow type, granulator technology, applied in the direction of die extrusion granulation, etc., can solve the problems affecting the service life and efficiency of the whole machine, troublesome maintenance and replacement work, increase the load of the rollers, etc., to achieve compact structure and flexible operation. Large, reducing the effect of the roller load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

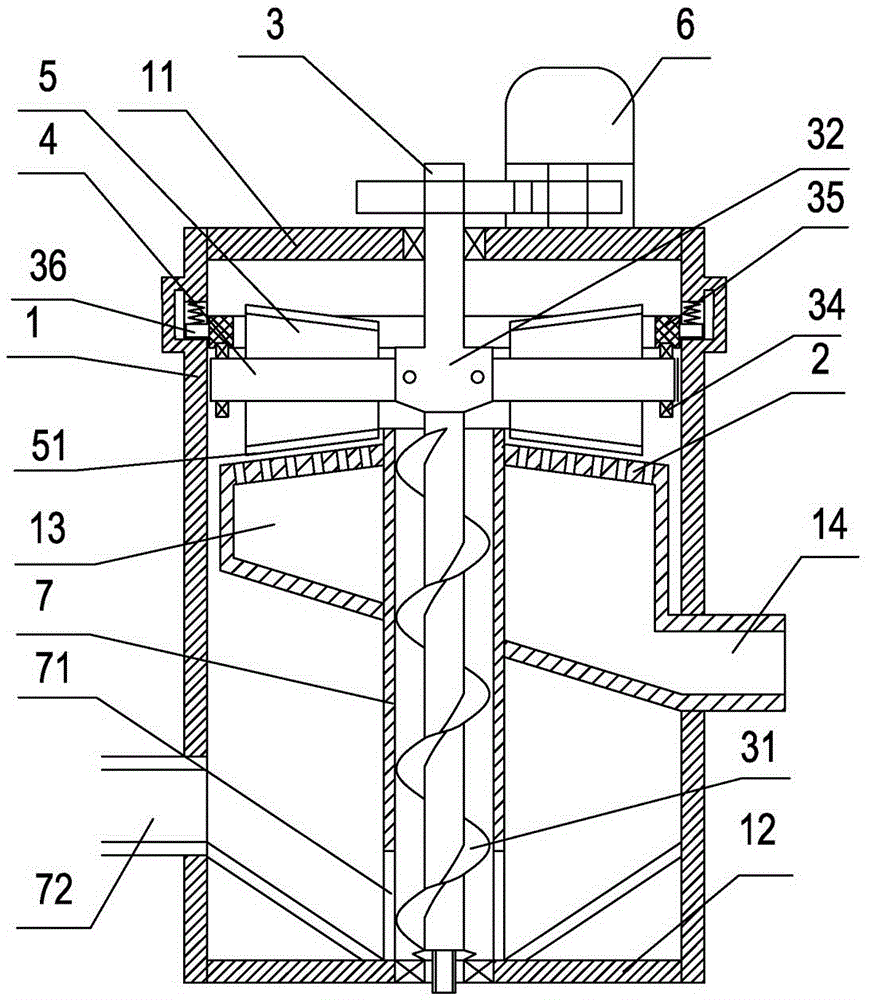

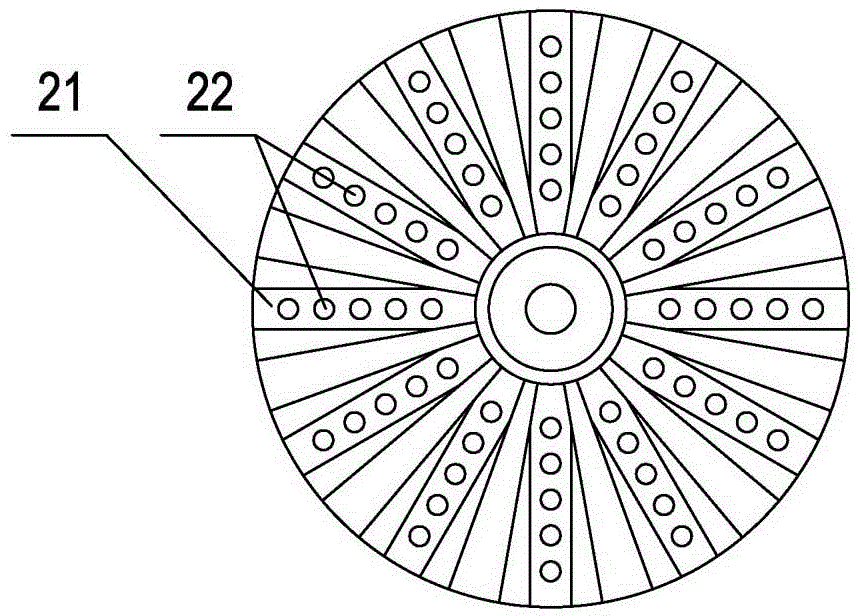

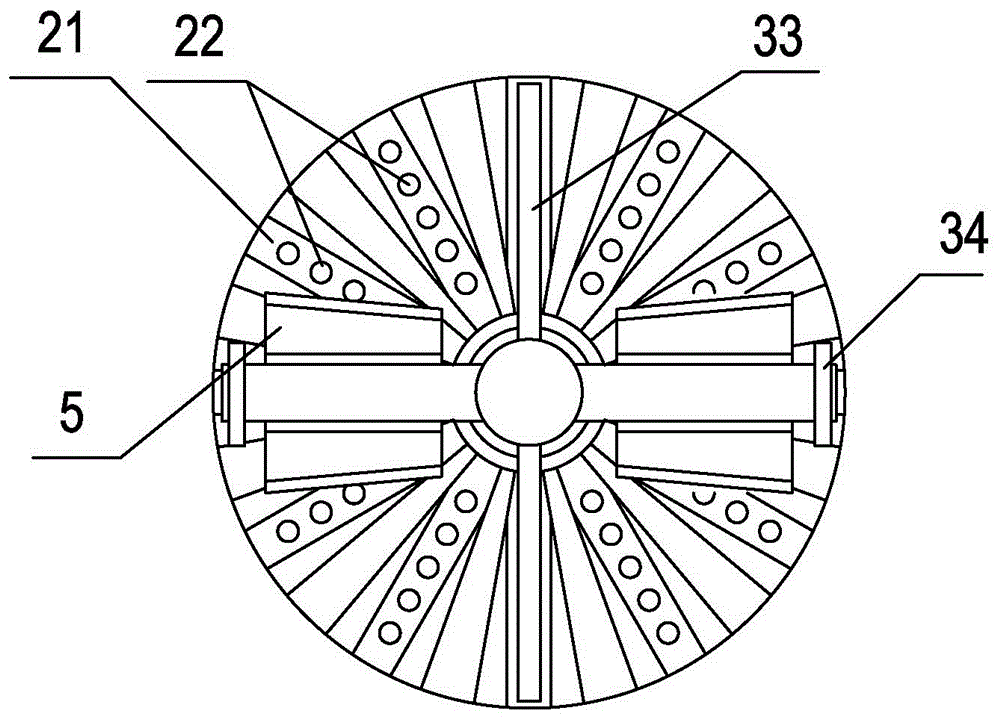

[0019] The flow type circulating batching extrusion granulator of the present invention comprises a shell 1, a sieve plate 2 fixedly installed in the inner cavity of the shell 1, a rotating shaft 3 arranged in the center of the shell 1, and a roller connected to the rotating shaft 3 Frame 4, the roller 5 mounted on the roller frame 4 through bearings, the upper end of the housing 1 is provided with a cover plate 11, and the lower end is provided with a bottom plate 12, the rotating shaft 3 is connected to the drive motor 6, and the rotating shaft 3 The upper end is rotatably connected to the cover plate 11 through bearings. The sieve plate 2 is a conical structure with a high center and low surroundings. The sieve plate 2 is provided with a sieve hole 22, and the bottom of the sieve plate 2 is fixedly connected to the finished product warehouse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com