A kind of compressed air foam side spray release device and using method

A technology of compressed air foam and foam, which is applied in fire rescue and other fields, can solve the problems that cannot meet the actual application requirements of side spray nozzles, is not suitable for installation and use on side walls, and affects the normal entry and exit of cars, etc., and achieves simple structure, large protection range, The effect of high foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

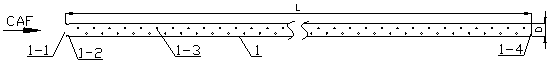

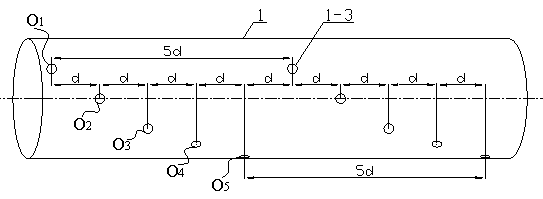

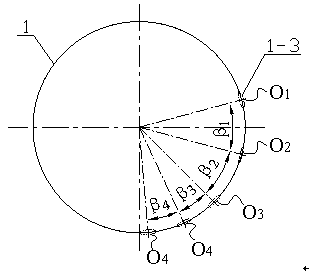

[0020] Such as figure 1 , 2 , 3, 4, and 7, the foam branch pipe 2 communicates with two release pipes 1 through the connection tee 3, wherein the release pipe 1 is made of galvanized steel pipe, the diameter D of the release pipe is 100mm, and the length L is 6m. Five rows of release holes 1-3 are evenly distributed on one side surface of 1 according to a certain distance and angle, and the number of release holes 1-3 from top to bottom is o 1 , o 2 ...o 5 , the hole diameters of each row of discharge holes 1-3 are 8mm, 8mm, 8mm, 6mm, and 6mm from top to bottom, and the horizontal distance between two adjacent discharge holes is 50mm. The distance d between the discharge holes is 250mm, and the angles between each row of release holes are 30°, 30°, 20°, and 20° from top to bottom, among which, according to the formula The foam inlet cross-sectional area A of the release pipe 1 can be calculated 1 0.00785 m 2 , according to the formula The total cross-sectional area A ...

Embodiment 2

[0030] Example 2 as Figure 5 , 6 , 7, the release pipe 1 communicates with the foam branch pipe 2 through the connection tee 3, wherein the release pipe 1 is made of galvanized steel pipe and is arc-shaped, the diameter D of the release pipe is 100mm, and the length L is 10m. Six rows of discharge holes 1-3 are evenly distributed on the surface according to a certain distance and angle, and the discharge holes 1-3 are numbered from top to bottom as o 1 , o 2 ...o 6, the diameter of each row of discharge holes 1-3 is 8mm, the horizontal distance between two adjacent discharge holes is 70mm, the distance d between two adjacent holes in each row of discharge holes is 420mm, and the release holes in each row are evenly arranged On the surface of the discharge pipe, the angles between the rows of discharge holes are 35°, 40°, 40°, 40°, and 35° from left to right, that is, the 190° arc surface of the discharge pipe is covered. In this embodiment The compressed air foam side spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com