FRP (fiber reinforce plastic) rod armored nonmetal rat-proof optical cable and manufacture process thereof

A manufacturing process, non-metal technology, applied in the field of FRP rod armored non-metal rodent-proof optical cable and its manufacturing process, can solve the problems of lack of lightning protection performance, unsatisfactory rodent-proof effect, low production efficiency, etc. Optical cable communication failure, simple optical cable structure and processing technology, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] see figure 1 , Figure 3 to Figure 6 , embodiment 2 includes:

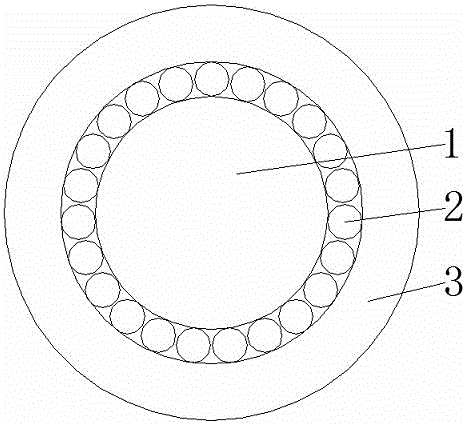

[0036] An FRP rod armored non-metal rodent-proof optical cable, comprising an optical cable core 1, an FRP rod armor layer and an outer sheath 3, the optical cable core 1 is covered with the FRP rod armor layer, and the FRP rod The rod armor layer is covered with the outer sheath 3, the FRP rod armor layer is a glass fiber reinforced plastic rod, and the FRP rod armor layer is arranged in an SZ twisted manner by a plurality of FRP rods 2 A fully-covered FRP rod armor layer is formed around the optical cable core 1, and the material of the outer sheath 3 is HDPE sheath material added with anti-rodent repellent.

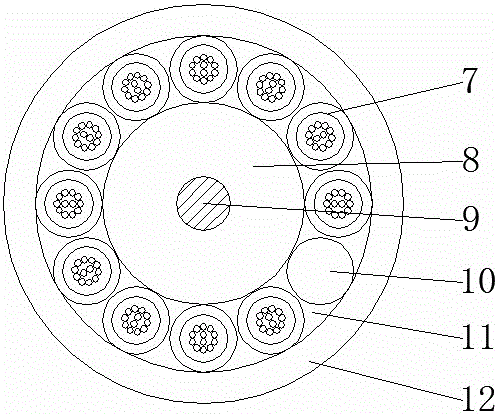

[0037] The optical cable core 1 is a layer-stranded cable core, including an optical fiber loose tube 7, a cushion layer 8, a central reinforcement FRP 9, a filling rope 10, a cable compound or a dry water-blocking material 11, and an inner sheath 12. The reinforcement FRP 9 is covered with a cus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com