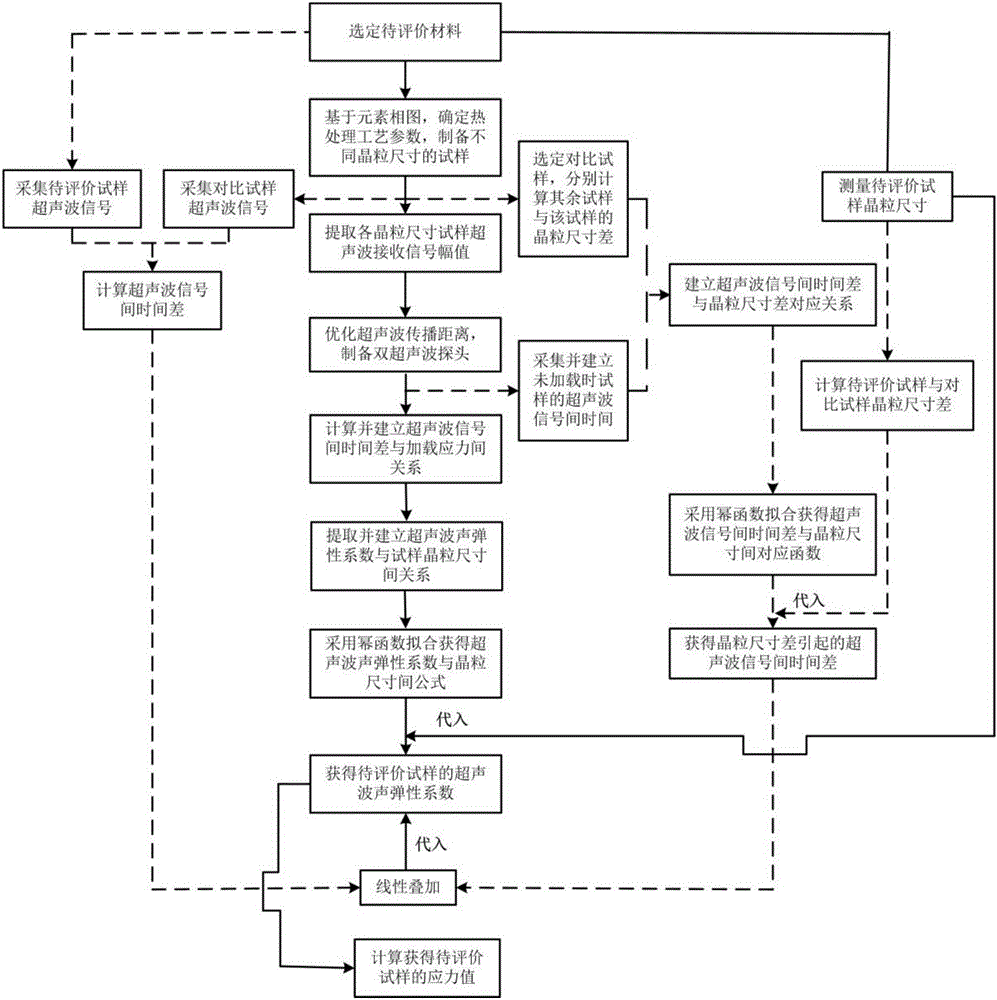

Correcting method for evaluating material stress by influencing ultrasonic waves through grain sizes

A technology of grain size and material stress, which is applied in the direction of material analysis, material analysis, and detection response signal processing using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as difficulty in accurately measuring ultrasonic propagation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Select Q235 steel as an example to describe the correction method of grain size affecting ultrasonic evaluation of material stress. The specific process is as follows:

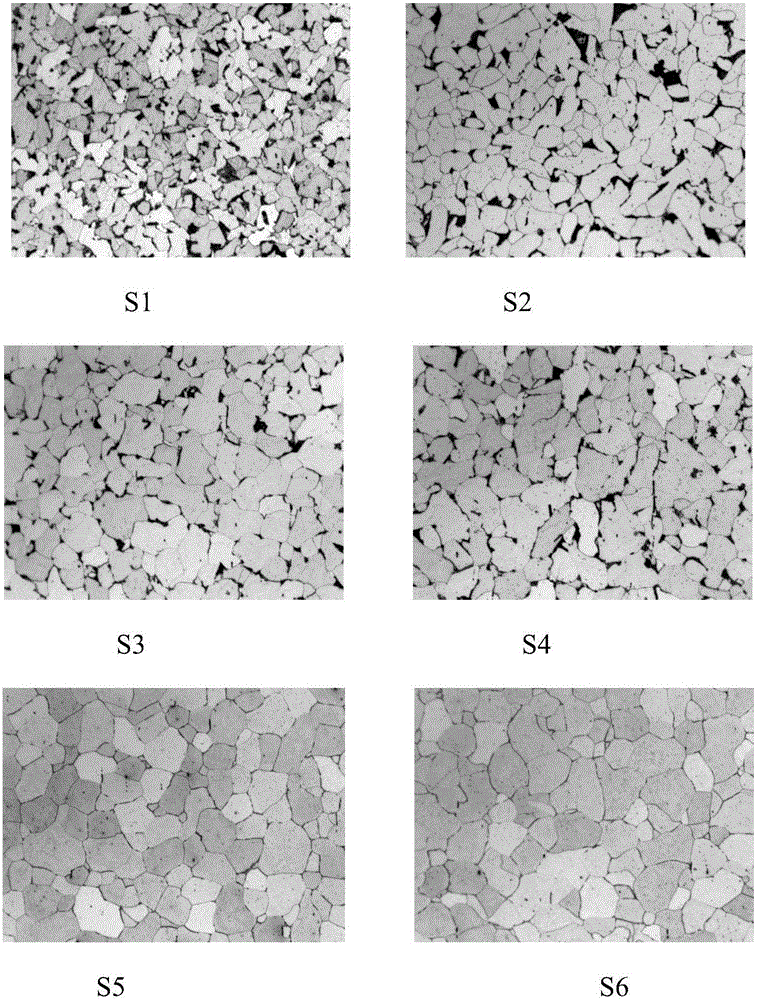

[0031] 1. Select Q235 steel as the evaluation object, combine the Fe-C binary alloy phase diagram to formulate the heat treatment process curve, and obtain six groups of Q235 steel samples with different grain sizes, which are respectively marked as S1-S6 ( figure 1 shown). The heat treatment process and the grain size of each sample are shown in Table 1.

[0032] Table 1 Heat treatment process parameters and grain size of Q235 steel

[0033]

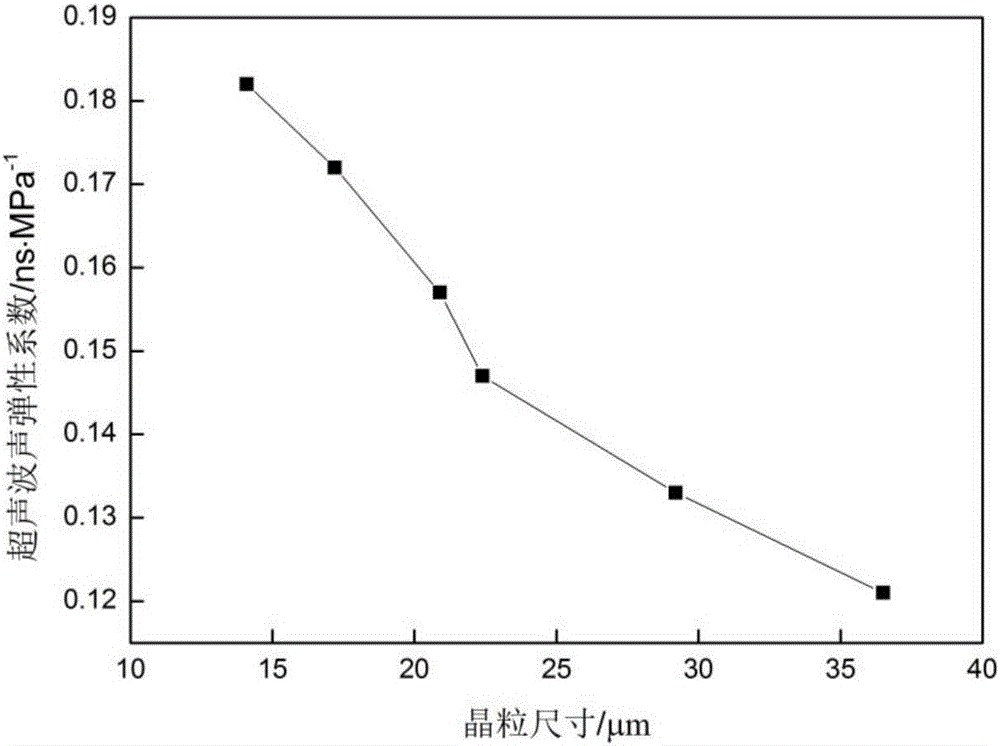

[0034] Step 2: Optimizing the excitation parameters of the ultrasonic signal, collecting the ultrasonic signals of the S1-S6 samples sequentially at intervals of 20mm, extracting the amplitude of the ultrasonic receiving signal at each propagation distance, and establishing the corresponding relationship between the amplitude of the ultrasonic receiving signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com