Ultrasonic phased array pipeline ring weld detection mechanism capable of moving stably

An ultrasonic phased array and detection mechanism technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices. Reliability, guaranteed smooth fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

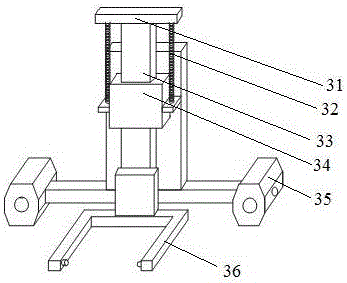

[0065] As shown in the accompanying drawings, the ultrasonic phased array pipeline girth weld detection mechanism that can move smoothly in this patent is used to detect flaws in the pipeline girth weld with an acoustic wave flaw detection instrument equipped with a flaw detection probe 8, including a main body and a fastening device 2. The left and right flaw detection probe brackets 10 and the left and right flaw detection probes 8 .

[0066] The main body includes a base 1, a first slide bar, a second slide bar, a slide bar top wire 11, a left and right slide bar coupling frame 35, a magnetic wheel 4 and a wheel shaft; the base 1 is hollow inside, and the side of the base 1 is provided with There are a first slide hole and a second slide hole parallel to each other; the first slide rod is set in the first slide hole; One slide hole and / or the second slide hole are provided with a top wire hole connected with the slide hole, and a slide rod top wire 11 is provided in the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com