Evaporation tank cleaning equipment

A technology for cleaning equipment and evaporating tanks, used in lighting and heating equipment, flushing, cleaning heat transfer devices, etc., can solve the problems of unstable rotation, insufficient rigidity of the secondary joint arm, and unsmooth rotation of the primary joint arm, etc. Achieve the effect of reducing friction, avoiding unstable rotation, and reducing torque load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

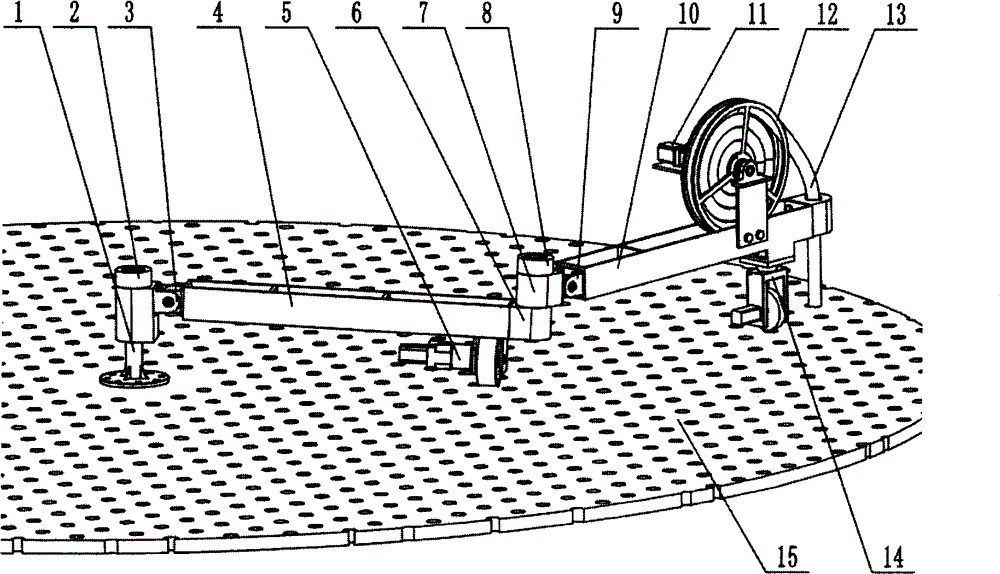

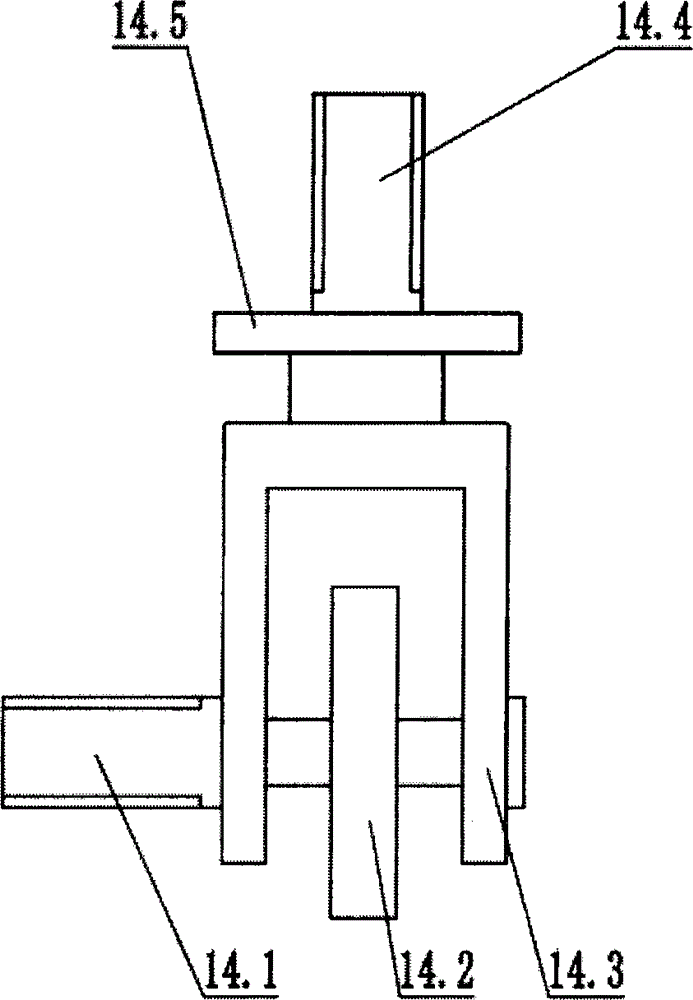

[0016] An evaporation tank cleaning device of the present invention, as attached figure 1 , attached figure 2 As shown, it includes a central rotary support 1, a first angle sensor 2, a first hinge mechanism 3, a first articulated arm 4, a first articulated arm drive mechanism 5, a first rotary seat 6, a second rotary seat 7, a second Angle sensor 8, second hinge mechanism 9, second articulated arm 10, water pipe feed drive mechanism 11, water pipe turntable 12, water pipe 13, second articulated arm drive steering mechanism 14. Among them, the central slewing support 1, the first articulated arm 4, the first slewing seat 6, the second slewing seat 7, the second articulated arm 10 and the water pipe turntable 12 form the backbone mechanism; the first angle sensor 2 and the second angle sensor 8 form the The angle sensor group; the first hinge mechanism 3 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com