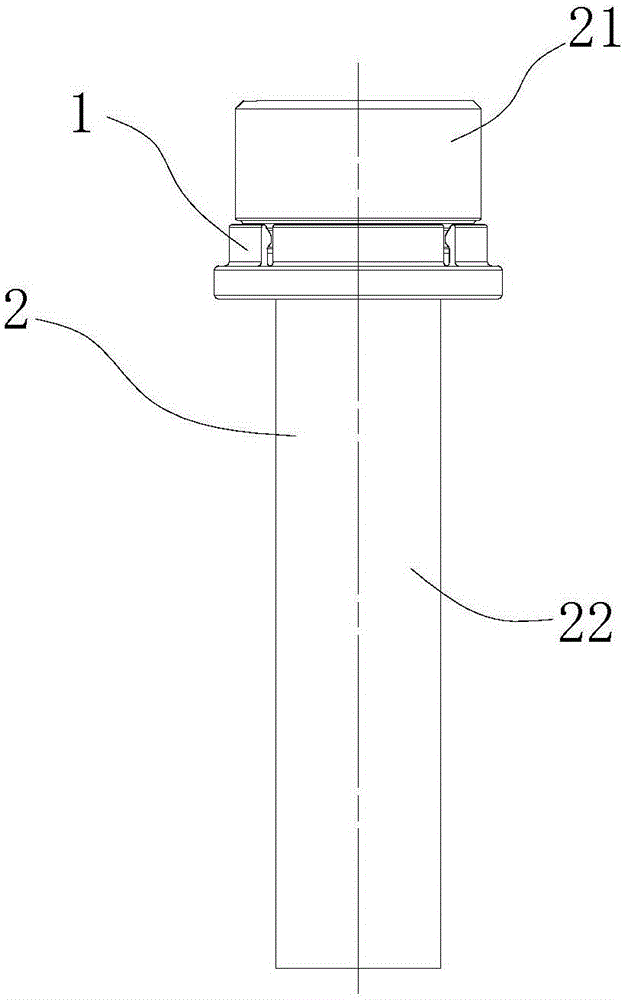

Gasket, screw and screw assembly

An assembly and screw technology, applied in the direction of screws, washers, threaded fasteners, etc., can solve the problems of repeated use of unfavorable washers, scattered washers, easy loss, etc., and achieve the effect of improving elasticity, avoiding loss, and easy snapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

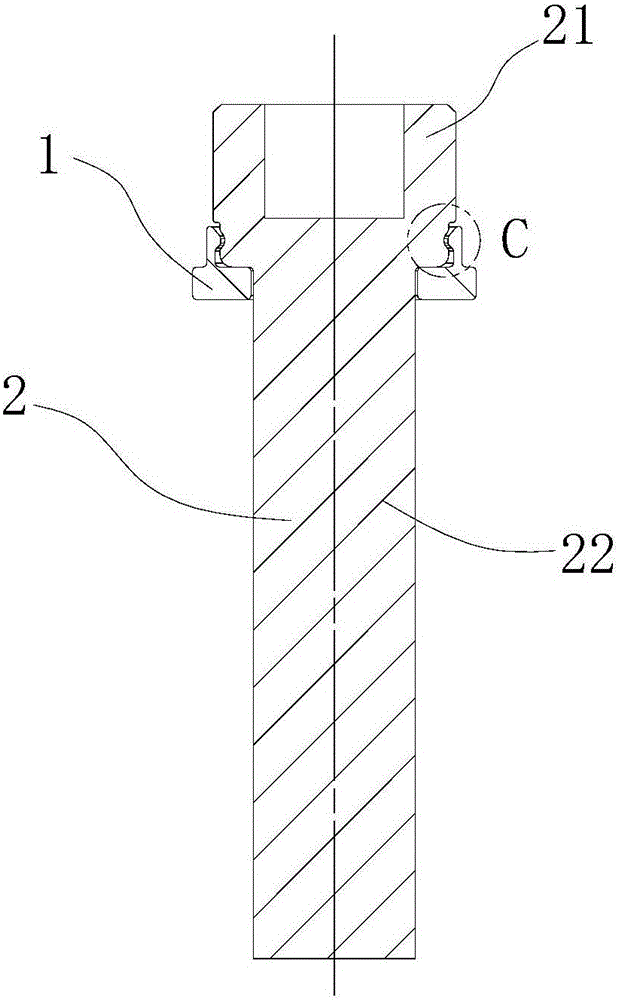

[0024] The present invention will be further described below in conjunction with accompanying drawing.

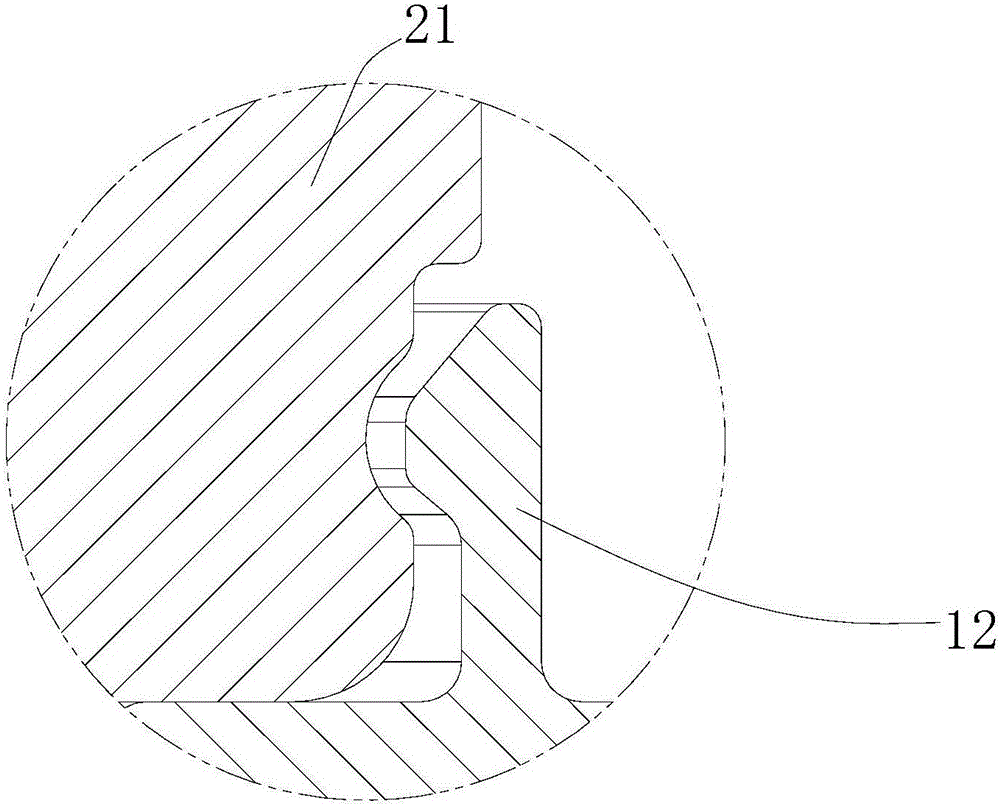

[0025] Such as Figure 4 and 5 As shown, the gasket of the present invention includes an annular ring body 11, the upper and lower surfaces of the ring body 11 are respectively a screw contact surface and an object contact surface, and the screw contact surface is provided with an annular locking protrusion 12, A washer locking structure 13 is provided on the inner ring surface of the locking protrusion 12 . The clamping protrusion 12 and the ring body 11 are usually integrally formed, the clamping protrusion 12 is coaxial with the ring body 11, and the washer clamping structure 13 on the inner ring surface of the clamping protrusion 12 is used to engage the screw on the screw head 21 The connection structure is matched with the card connection. The clamping structure generally adopts a buckle slot structure, and the slot and the buckle are respectively set on the washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com