Operation rotating speed and flow rate control module of pneumatic diaphragm pump

A pneumatic diaphragm pump, flow control technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc., can solve problems such as affecting the operation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

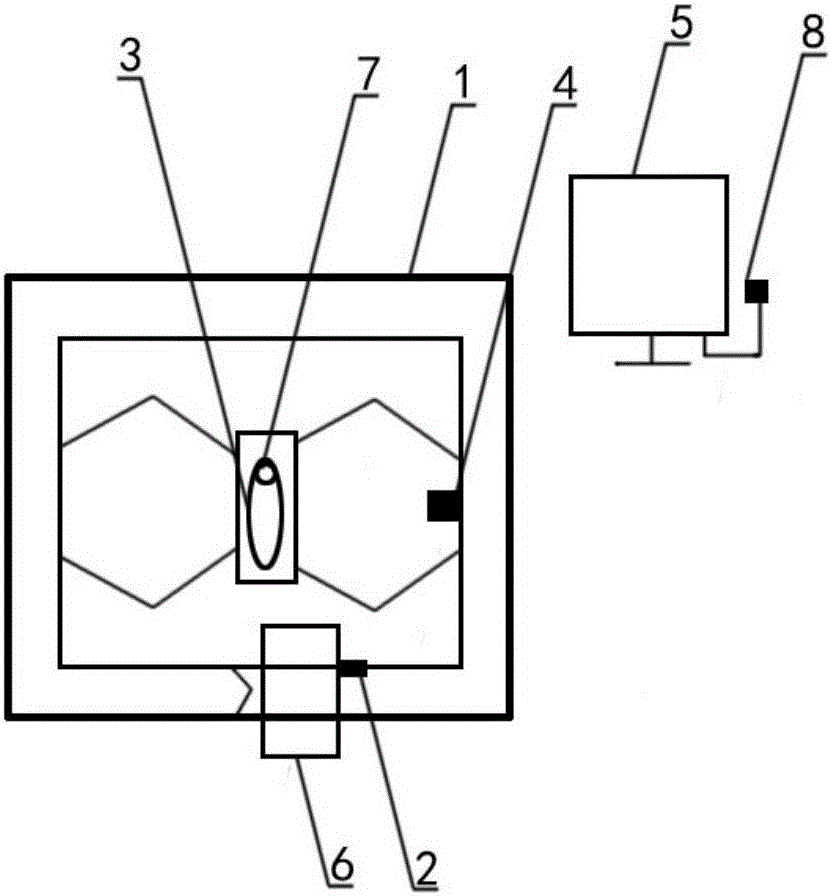

[0012] Embodiment: as shown in the accompanying drawing. The operating speed and flow control module of the pneumatic diaphragm pump includes a body (1), and a flow sensing module (2), a speed sensing module (3), a pressure sensing module (4), and a management module (5) are arranged on the body (1), The flow sensing module (2) senses the flow condition in the machine body, the speed sensing module (3) senses the operating speed of the pump body, the pressure sensing module (4) senses the value of pressure applied by the operation, and the sensed information is processed by the management module (5).

[0013] The operating speed and flow control module of the pneumatic diaphragm pump is provided with a particle buffer module (6) on the flow sensing module (2) to buffer excessive material particles when the flow rate is too large.

[0014] The operating speed and flow control module of the pneumatic diaphragm pump is provided with a setting module (7) on the speed sensing modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com