Power supply system of heavy-duty car SCR system

A technology of SCR system and power supply system, which is applied in the direction of electric control of exhaust treatment device, exhaust treatment, mechanical equipment, etc. It can solve the problems that the SCR system cannot work normally and affects the normal use of vehicles, and achieves simple structure and reliability High, the effect of small circuit changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

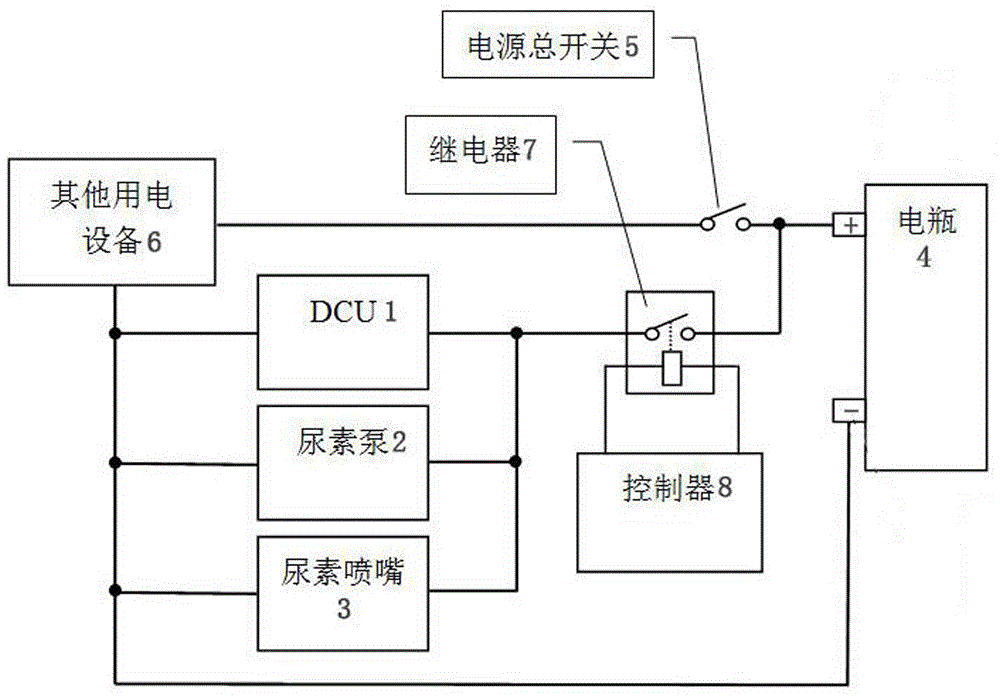

[0016] like figure 1 As shown, the power supply system of the heavy-duty vehicle SCR system of the present invention includes a DCU1, a urea pump 2, a urea nozzle 3, a storage battery 4, a main power switch 5, other electrical equipment 6, a relay 7 and a controller 8 for controlling the relay. The timer 8 is provided with a timer. After the DCU1, urea pump 2, and urea nozzle 3 are connected in parallel, their power supply pins are connected to the positive pole of the storage battery 4 through a relay 7, and the power supply pins of other electrical equipment 6 are connected through the main power switch. 5 is connected to the positive pole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com