Silencer of microtype gas thruster

A technology of gas propeller and noise reduction device, which is applied in the direction of noise reduction devices, machines/engines, engine components, etc., can solve problems such as noise pollution, equipment and device damage, air pollution, etc., to avoid vibration and damage, improve noise reduction effect, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

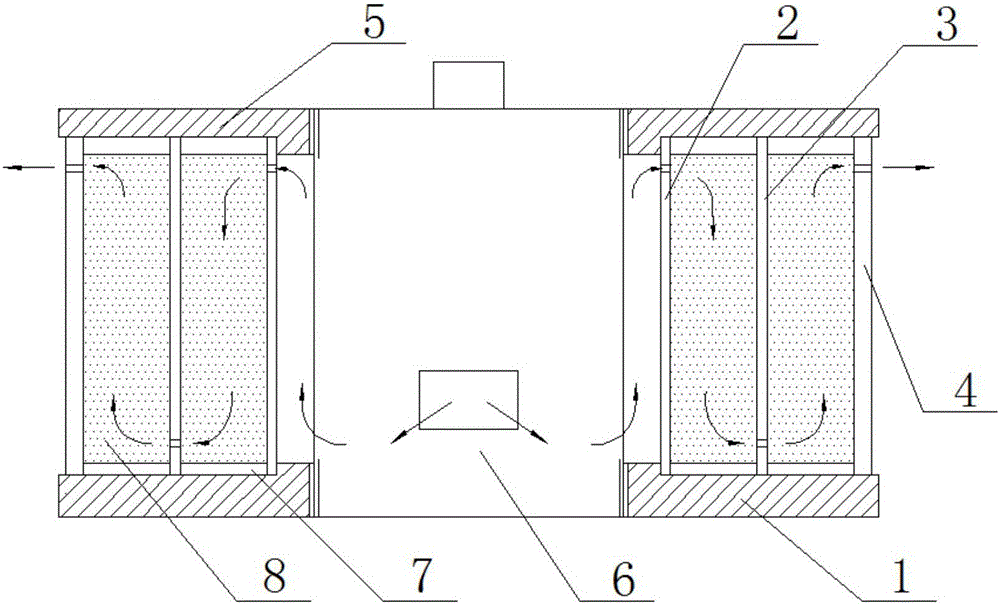

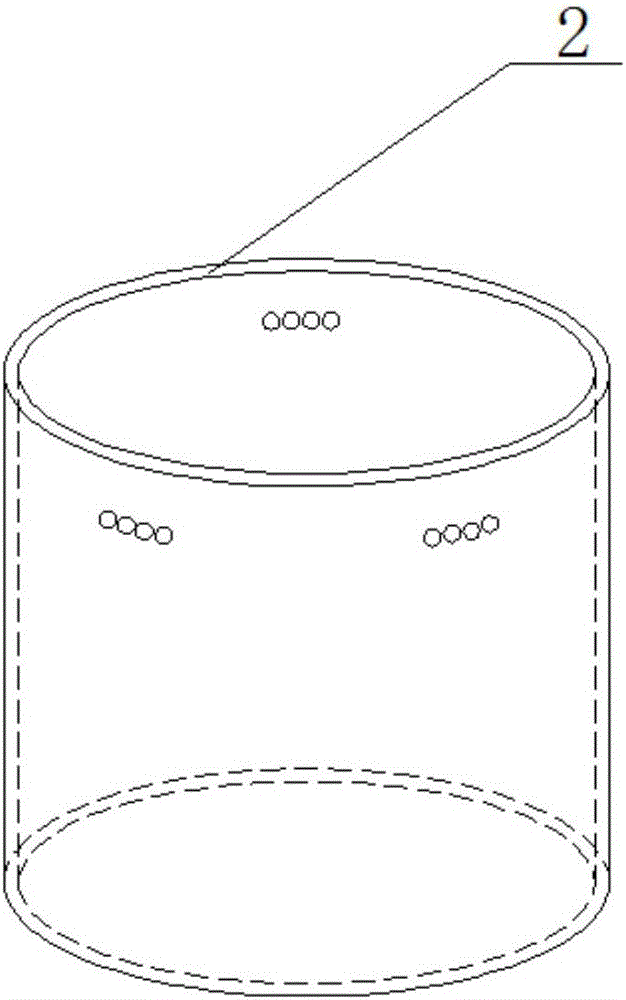

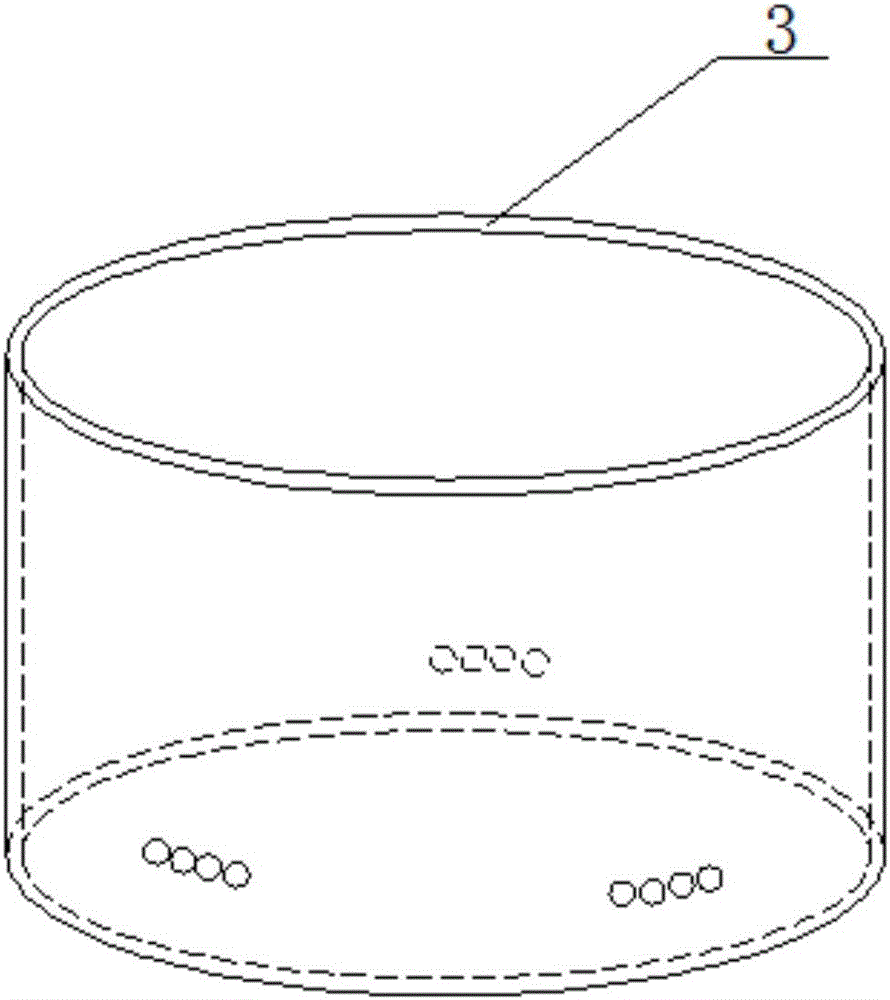

[0018] Such as Figure 1 to Figure 5 As shown, a kind of miniature gas propulsion silencer device in the present embodiment comprises a base 1 and a top cover 5, wherein: it also includes a first silencer circle 2, a second silencer circle 3, an outer circular shell 4, a fixing ring 7 and aluminum foam 8, the base 1 is threadedly connected to the lower end of the miniature gas propeller 6, and the first sound-absorbing ring 2, the second sound-absorbing ring 3 and the outer shell 4 are sequentially arranged on the periphery of the micro-gas propeller 6 and Its lower end is in contact with the base 1, and the aluminum foam 8 is filled in the middle of the first sound-absorbing ring 2 and the second sound-absorbing ring 3 to form a primary silencer, and the foam aluminum 8 is filled in the middle of the second sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com