Double-side-sealed sliding window

A sliding window, double-sided technology, applied in the field of sliding windows, can solve the problems of poor sealing effect, easy falling off of sealing strips, and inability to seal well, etc., to prevent noise, reduce noise pollution, and solve the effect of poor sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

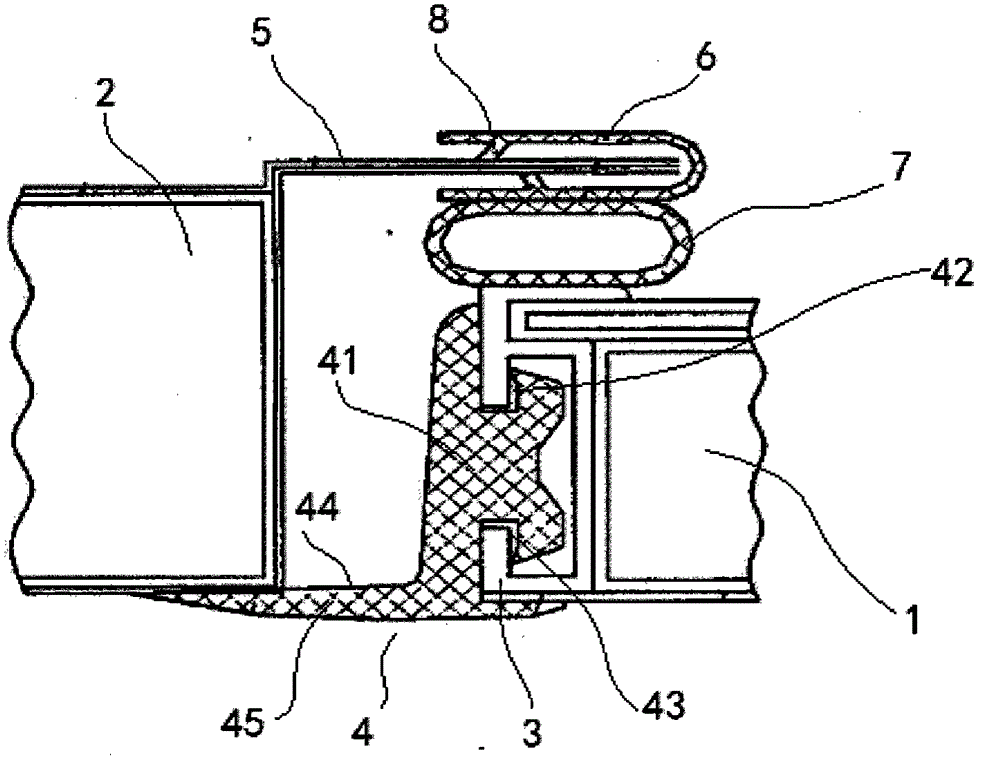

[0012] see figure 1 , a double-sided sealed sliding window, including a window frame 1 and a sliding window 2 arranged in the window frame 1, the inner side of the window frame 1 is installed with a first sealing strip 4 through an aluminum profile 3, and the first The sealing strip 4 includes a base portion 41 embedded in the aluminum profile 3 and a T-shaped outsourcing portion 45 that is connected to the outside of the base portion 41 and protrudes in the opposite direction. The inside of the sliding window 2 is provided with a A sealing stop 5, the sealing stop 5 is provided with a second U-shaped sealing strip 6 through a plurality of elastic clips 8, and an oval hollow first sealing strip 6 is connected to the inner side of the second sealing strip 6. Three sealing strips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com