Pressure test structure for long bored cast-in-situ pile and test method

A technology for bored piles and pressure testing, which is applied in the testing of foundation structures, foundation structure engineering, construction, etc. performance, ease of implementation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

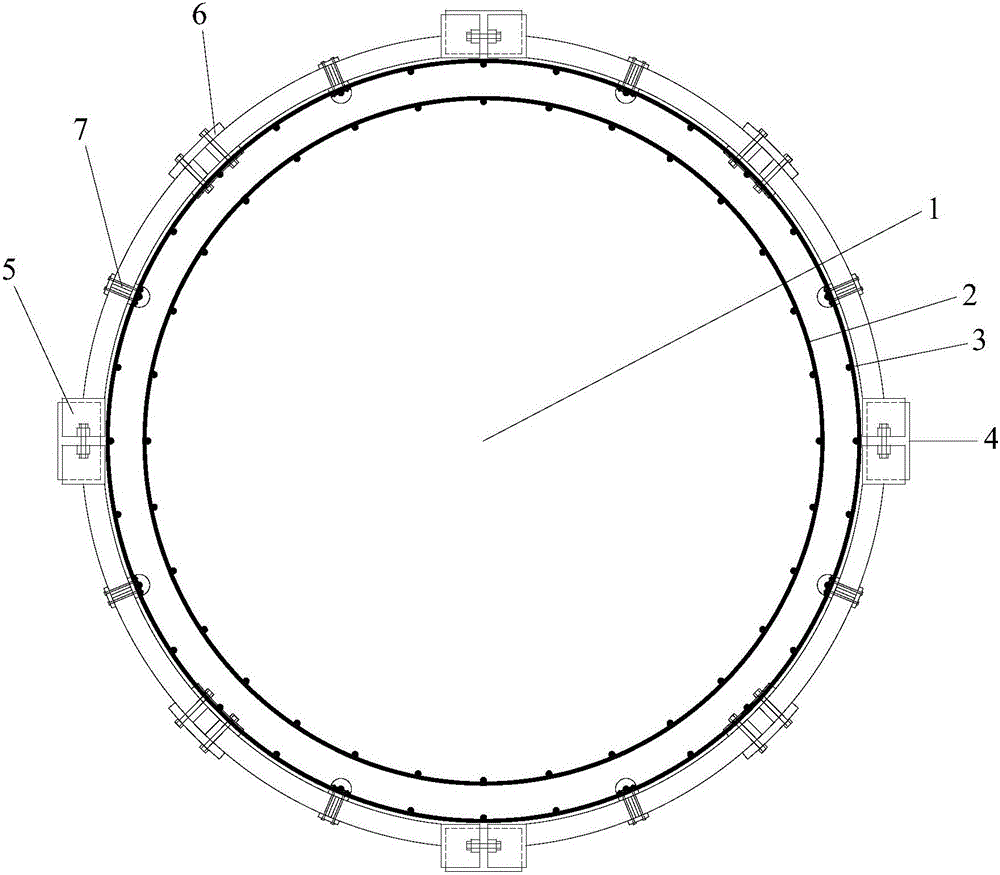

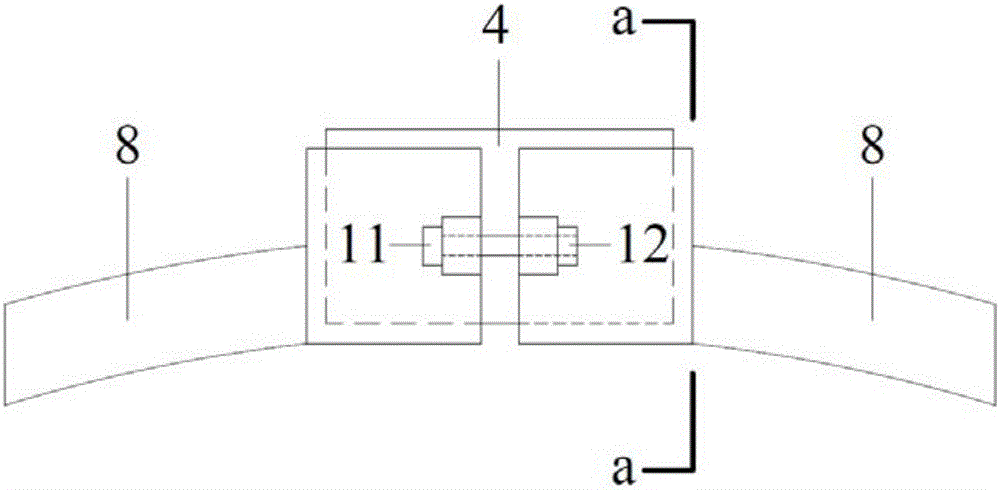

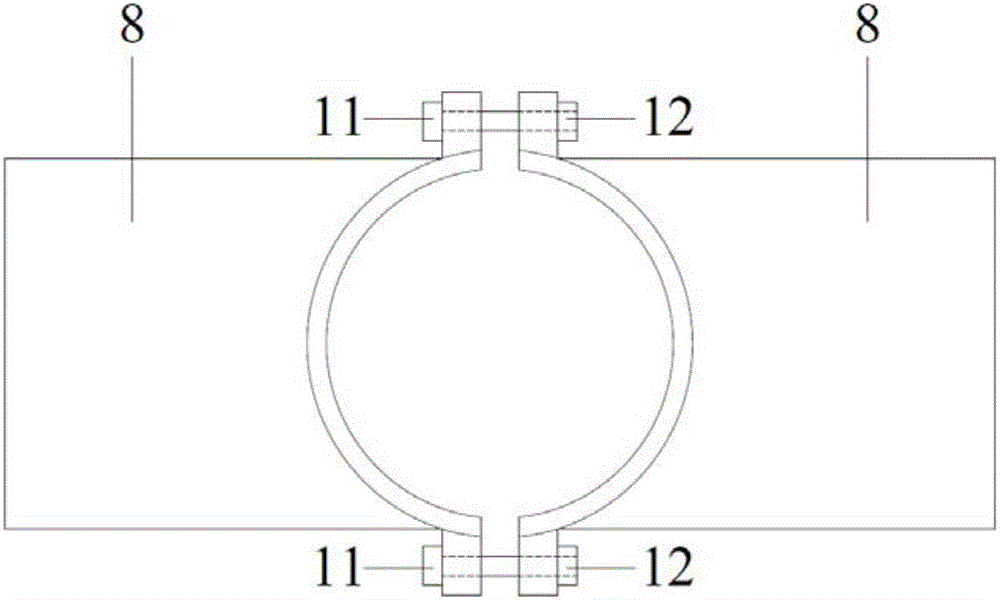

[0056] see figure 1 , figure 2 , image 3 and Figure 4 The shown large-diameter deep-length bored piles (including bored pile 1, reinforcement cage 2 and main reinforcement 3) and test method components (earth pressure box 4, earth pressure box protection and fixing device 5, earth pressure box lock The connecting part between the tightening device 6, the positioning and locking device between the connecting part and the main reinforcement of the steel cage 7, the main board 8, the auxiliary board 9, the vertical board 10, the screw 11 and the bolt 12), the pile length is 80m, and the pile side soil is respectively muddy Silty clay, silt, silt and silty clay, among them, silty silty clay up to 16m thick, silt up to 34m thick, silty sand up to 5m thick, silty clay up to 25m thick, and the pile foundation is designed as a friction pile , and bear a relatively large vertical load, the pile foundation is mechanically drilled, the ground is prefabricated with a steel cage, and...

Embodiment 2

[0058] (1) According to the "Technical Specifications for Building Pile Foundation Inspection" (JGJ 106-2003), select the appropriate earth pressure sensor according to the sensor technology and environmental characteristics, and according to the "Technical Specifications for Building Foundation Pit Engineering Monitoring" (GB 50497- 2009) Select the range of the earth pressure cell as well as the measurement accuracy and resolution;

[0059] (2) According to the "Technical Specifications for Monitoring Construction Foundation Pit Engineering" (GB 50497-2009), install the earth pressure cell into the earth pressure cell protection and fixing device. protection, and can form a good contact with the concrete on the pile side, and will not enter the earth pressure box protection and fixing device when the concrete is poured. Secondly, before locking the side of the half cylinder shell, the earth pressure box and the half cylinder The gap between the sides of the casing is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com