Construction method for milling cement soil stirring wall waterproof curtain through double wheels

A technology of cement-soil mixing wall and water-stop curtain, which is applied in the construction field of water-stop curtain and water-stop curtain of cement-soil mixing wall, can solve the problems of poor anti-seepage effect, unstable pile quality of three-axis mixing piles, etc. The effect of less soil replacement, less mud transportation, and high construction efficiency

Inactive Publication Date: 2016-08-24

ZHONGYIFENG CONSTR GRP

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a construction method of double-wheel milling cement-soil mixing wall water-stop curtain to solve the problems of unstable pile quality and poor anti-seepage effect of three-axis mixing piles in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

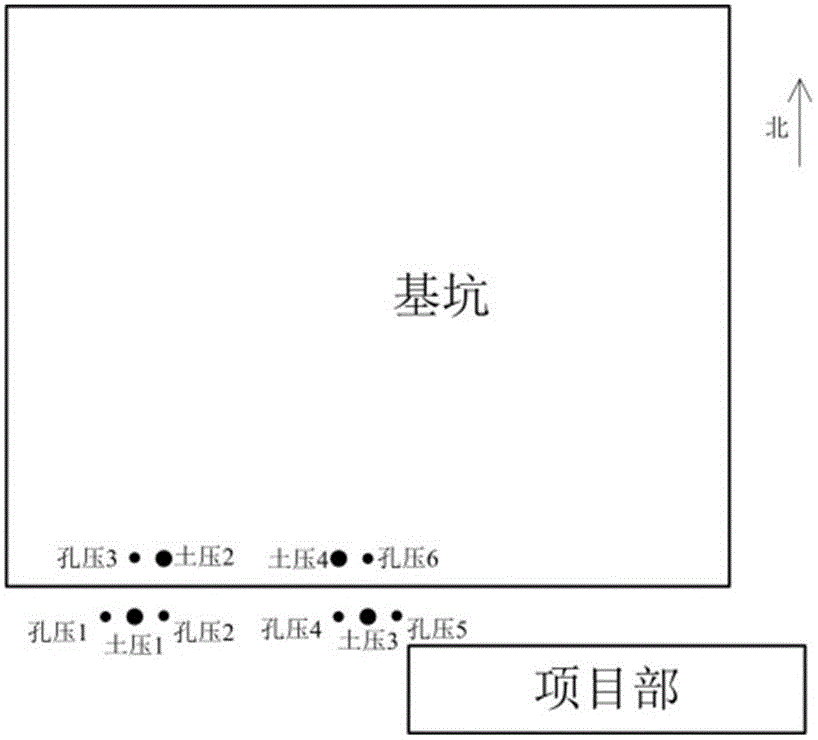

[0028] Example: see figure 1 As shown, a construction method of double-wheel milling cement-soil mixing wall water-stop curtain is used for the construction of the experimental site.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

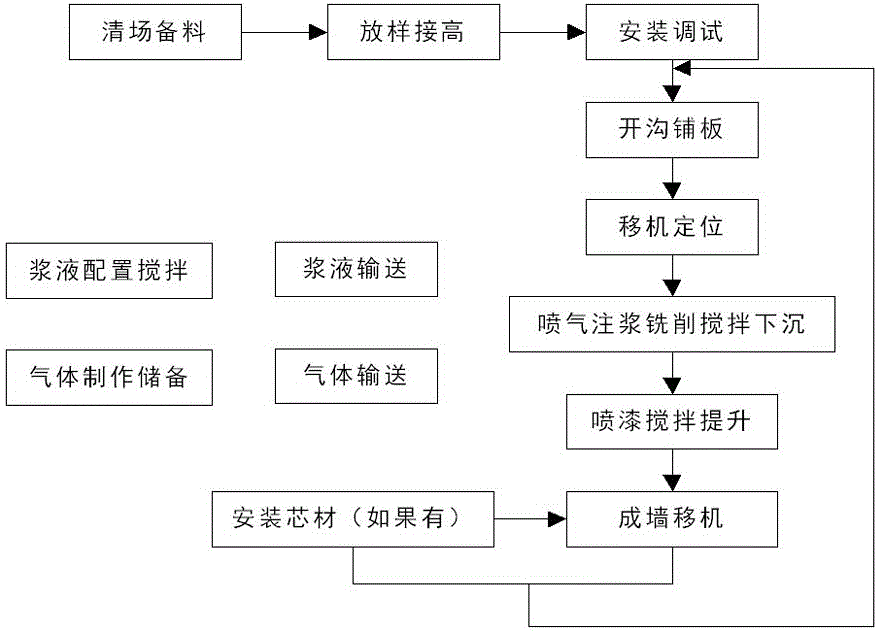

The invention discloses a construction method for milling a cement soil stirring wall waterproof curtain through double wheels. The construction method is characterized by comprising the following steps that firstly, surveying and setting out are conducted for positioning; secondly, a trench is excavated; thirdly, a double-wheel pile milling machine is arranged in place, a positioning red line is pulled to the construction side of the excavated trench, a framing point is set according to a surveying and setting-out result and marked, and the double-wheel pile milling machine is arranged in place; fourthly, at each frame of station, the double-wheel pile milling machine is used, a cutter head conducts cutting and digging and sinks to the target depth, meanwhile, cement grout is injected in a jetting manner, and the cement grout is injected in the jetting manner and stirred while the cutter head is elevated; and fifthly, after one frame of wall is constructed, the double-wheel pile milling machine is moved to the next position, the fourth step is repeated, and the next frame of wall is constructed till construction of the waterproof curtain is finished. According to the construction method, connectors are few, the water leakage risk caused by construction of cold joints can be completely avoided, and the construction efficiency is high. In the construction process, vibration is avoided, and safety performance is good. Replacement soil is little, environment friendliness is achieved, and outward transporting of slurry is reduced.

Description

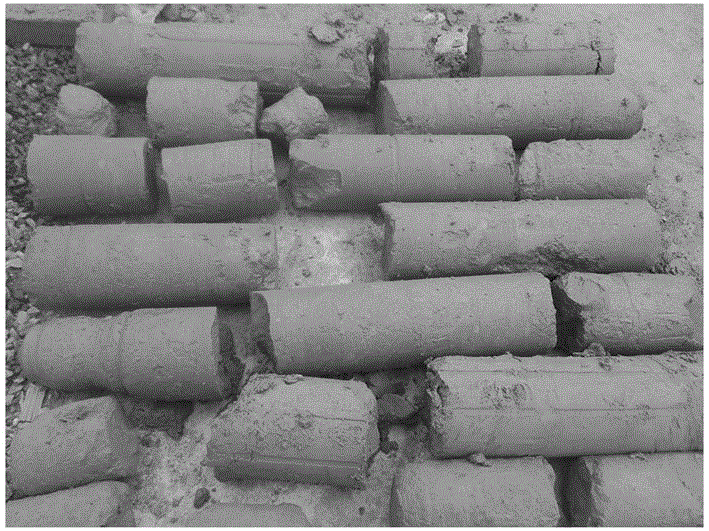

technical field [0001] The invention relates to a water-stop curtain, in particular to a construction method of a water-stop curtain for a cement-soil mixing wall, and belongs to the technical field of geotechnical engineering design and construction. Background technique [0002] In the coastal and southern regions where the groundwater level is relatively high, the water-stop curtain construction of the foundation pit protection project is an important part of the foundation pit project, and its form and construction machinery are also constantly developing. At present, the typical construction method with water-stop effect is the three-axis mixing pile. The three-axis stirring pile uses a three-axis stirring drilling tool to rotate in the vertical direction and inject grout to form a cylindrical improved pile body. The adjacent pile bodies are overlapped and overlapped to form a water-stop curtain. [0003] The construction of the three-axis mixing pile requires a 1.5m-w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D19/18

CPCE02D19/18

Inventor 牛洁雯程月红张翯张厚斌

Owner ZHONGYIFENG CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com