A covering assembly for covering bridge expansion joints

A technology covering components and expansion joints, applied to bridge parts, bridges, bridge construction, etc., can solve problems such as damage, installation and disassembly cost a lot of manpower and time, damage to the pavement matrix, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

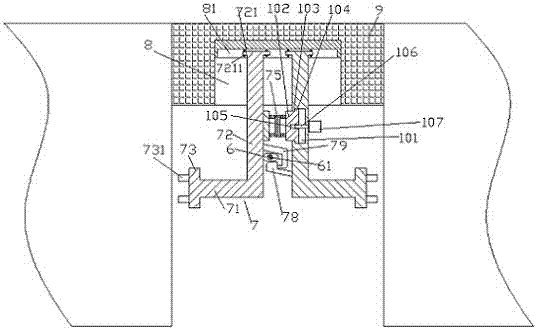

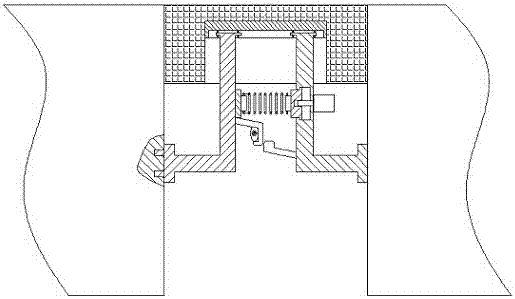

[0009] Combine below Figure 1-3 The present invention will be described in detail.

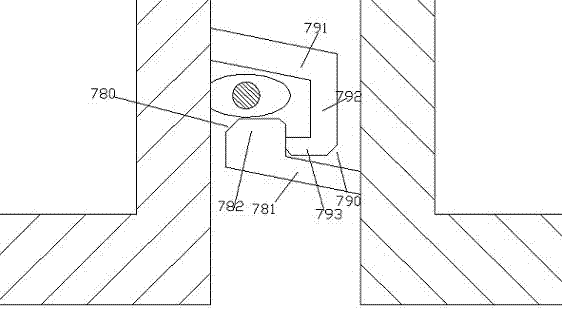

[0010] According to an embodiment, a covering assembly for covering bridge expansion joints is used to cover the road surface of the bridge expansion joints, and includes a rubber body 9 that is flush with the level of the bridge road surface and a rubber body 9 located inside the rubber body 9 Support body 8, and two extension support members 7 capable of moving toward and away from each other in the support body 8 and having a symmetrical structure, wherein each of the two extension support members 7 includes In the sliding groove 81 of the support body 8, a horizontally extended head 721 that slides horizontally, a vertical extension 72 connected to the horizontally extended head 721, and a lower end of the vertical extension 72 connected to the adjacent bridge The support arm 71 extended by the structure, wherein the ends of the two extension supports 7 are provided with a support plate 73 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com