A rack operating component

A component and rack technology, which is applied in the field of hosiery machine transfer devices, can solve problems such as complex mechanisms and achieve the effect of facilitating transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0047] The embodiment of the present invention provides a rack operating assembly.

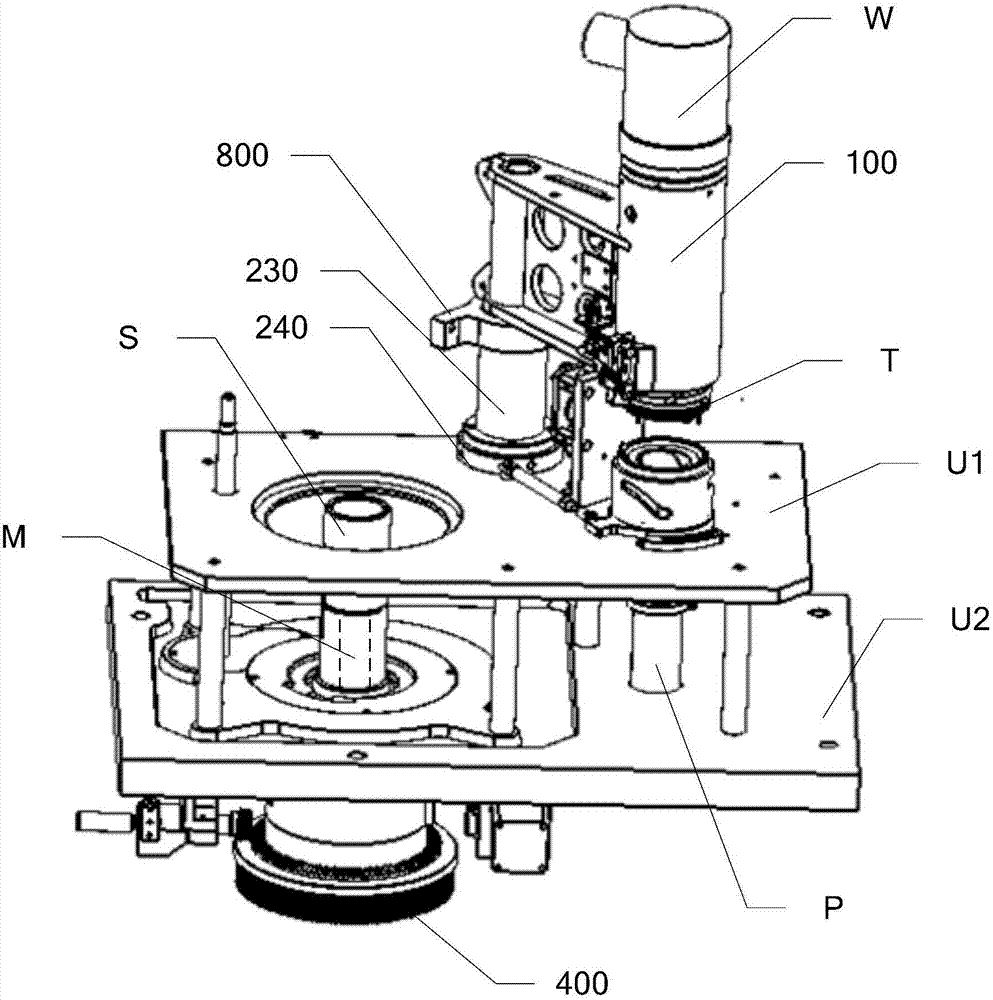

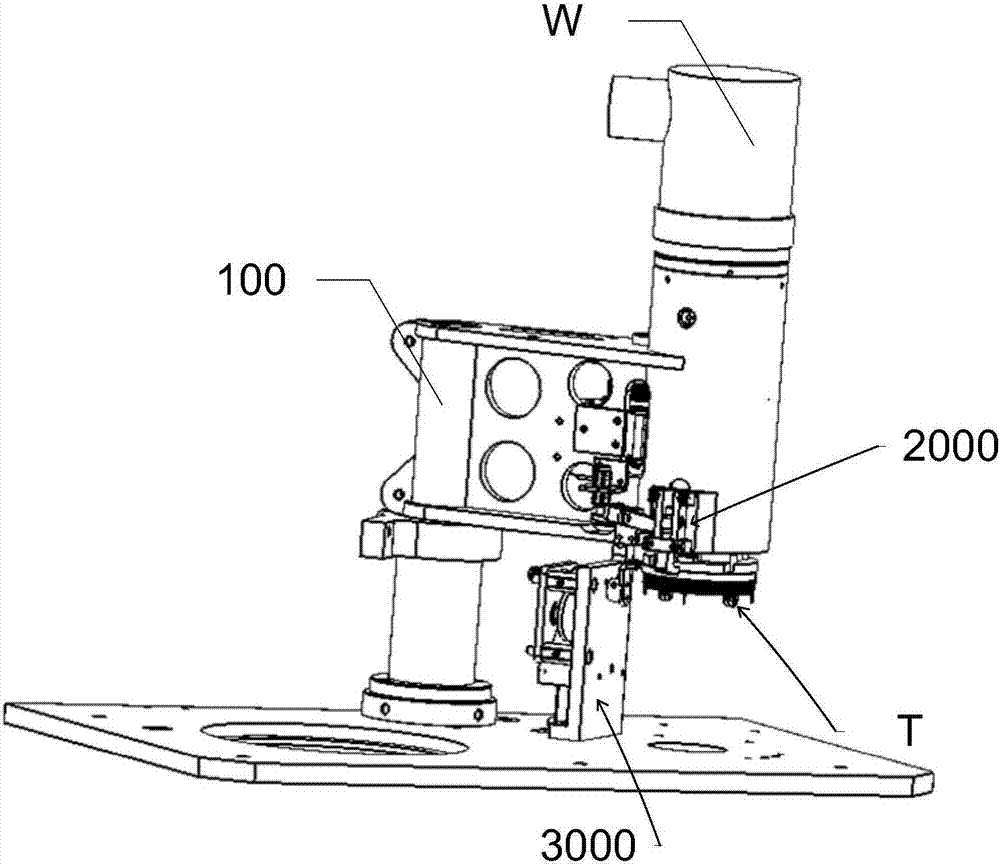

[0048] The hosiery machine transfer device is introduced below.

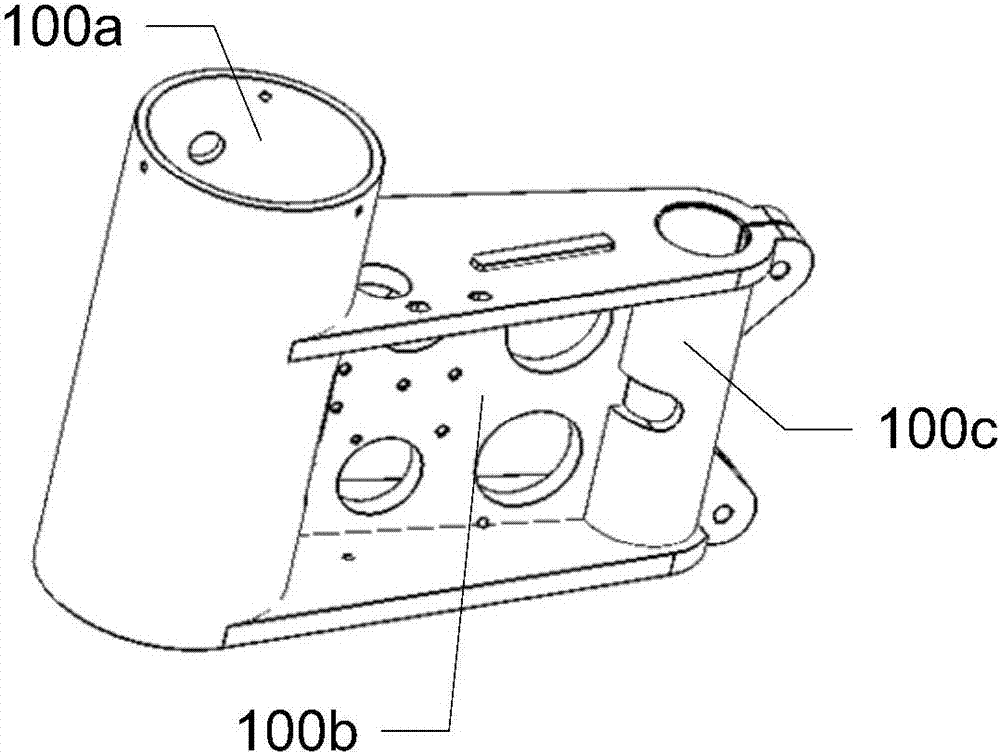

[0049] The hosiery machine transfer device may include: a turret 100 ; a central installation pipe 200 connected to the turret 100 ; and a transfer head installed on the central installation pipe 200 . The transfer head may include: a fixed half rack 140, which has at least one first functional tooth H1; an overturned half rack 120, which has at least one second functional tooth H2, which can be turned over relative to the fixed half rack 140 so that The first functional teeth H1 and the second functional teeth H2 are aligned, and the first functional teeth H1 and the second functional teeth H2 are of the same or different types.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com