Phosphating production method for automobile galvanized plate

A technology of phosphating treatment and production method, which is applied in the field of phosphating treatment process of automobile plates, can solve the problems of failure to find out, yellowing and blooming of phosphating plate surface, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] In order to better illustrate that the products prepared by the phosphating process of the present invention meet the standard requirements, further description will be made below in conjunction with specific examples.

[0104] In this implementation, five identical galvanized sheets are preferred, respectively labeled as 1, 2, 3, 4, and 5;

[0105] And ensure that the five galvanized sheets are completely activated and phosphated according to the process parameters in Table 2.

[0106] Table 2 Phosphating process parameters of galvanized sheet 1 to galvanized sheet 5

[0107]

[0108]

[0109] Above-mentioned galvanized sheet 1 ~ galvanized sheet 5 are processed by phosphating process, respectively obtain phosphating sheet 1, phosphating sheet 2, phosphating sheet 3, phosphating sheet 4 and phosphating sheet 5, for phosphating sheet 1 ~ The phosphating plate 5 is subjected to the neutral salt spray test, that is, the phosphating plate is placed in the test box, ...

Embodiment 2

[0116] In order to compare with the phosphating plate produced and prepared in Example 1, select the phosphating plate not prepared completely according to the process parameters required in Table 1, and the process parameters are as shown in Table 4, and the performance of the prepared phosphating plate is shown in the table 5.

[0117] Get two galvanized panels exactly the same as the galvanized panels used in Example 1.

[0118] Phosphating process parameters of galvanized sheet in table 4 comparative examples

[0119]

[0120] The performance test was carried out on the phosphating plate after meeting the above process parameters, and the table 5 was obtained.

[0121] The performance parameter of phosphating plate in the comparative example of table 5

[0122]

Phosphate film thickness (mm)

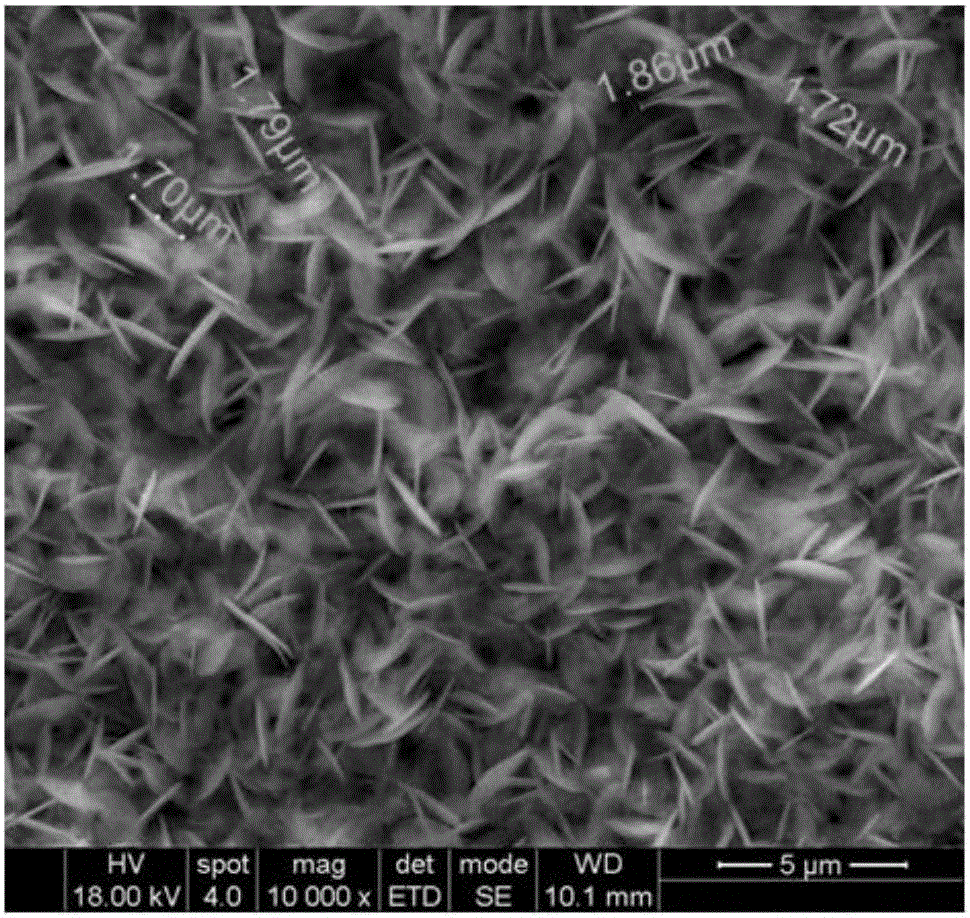

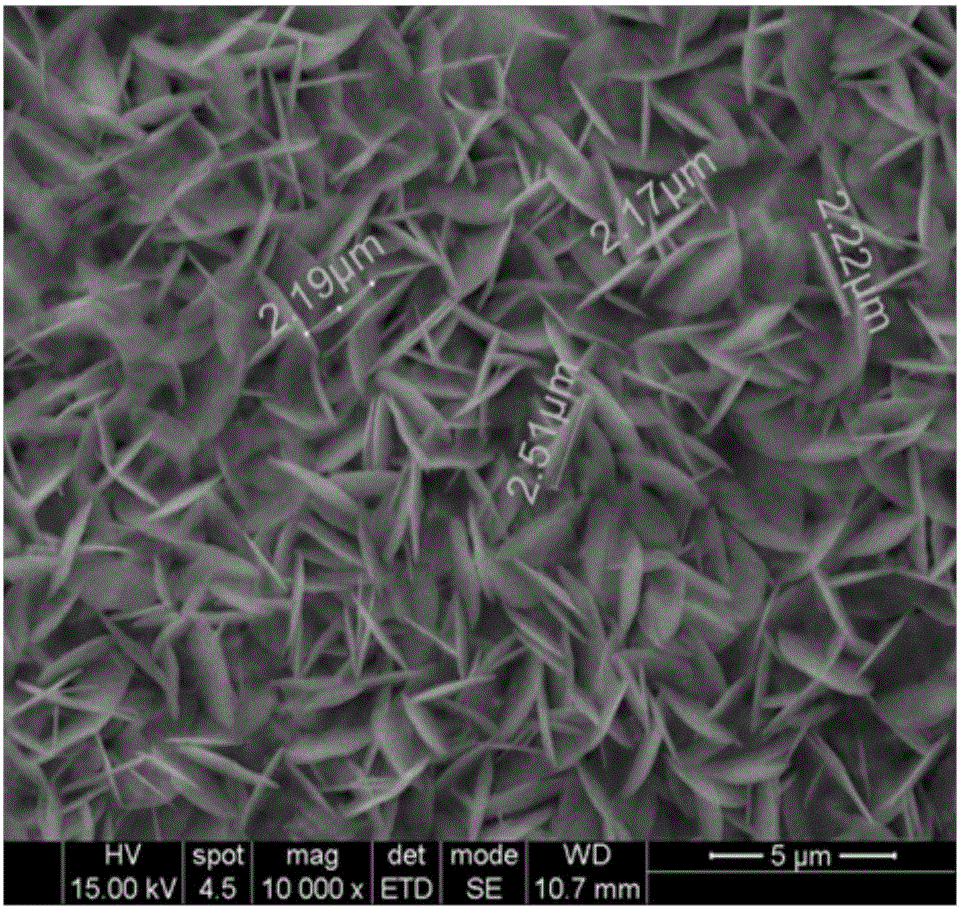

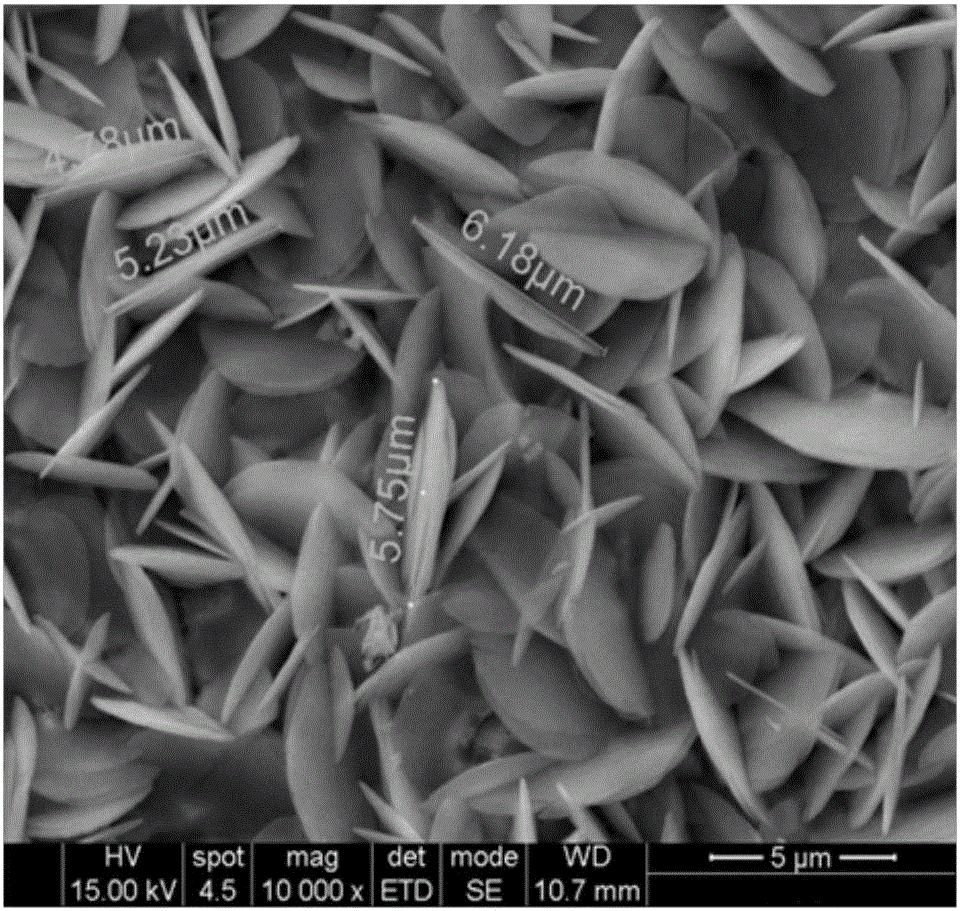

Grain microscopic size (μm)

Comparative example 1

2.8

5.0~6.0

Comparative example 2

3.4

6.0~7.0

[0123] It can be seen from Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com