Screwdriver for precision equipment

A technology of precision equipment and screwdrivers, applied in screwdrivers, wrenches, manufacturing tools, etc., can solve problems such as difficult alignment, effect effect, and single function, and achieve the effect of increasing service life and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings of the description.

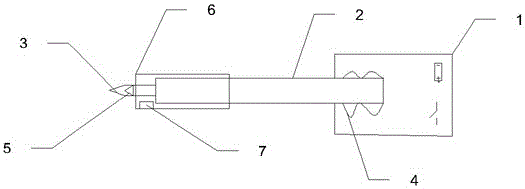

[0012] like figure 1 As shown, the screwdriver includes a handle 1, a cutter body 2 and a cutter head 3, the cutter body 2 goes deep into the handle 3, and the part where the cutter body 2 goes deep into the handle 1 is wound with a solenoid 4; the cutter body 2 and the cutter head 3 There are wires running through the interior, a light emitting diode 5 is provided at the position of the cutter head 3, and an auxiliary tube 6 is set on the cutter body, and an adsorption block 7 is arranged at one end of the auxiliary tube 6 close to the position of the cutter head.

[0013] The cutter body 2 and the cutter head 3 are fixedly connected, and the cutter body 2 and the cutter head 3 are made of electromagnetic materials, the diode 5 is connected in parallel with the solenoid and controlled by the power supply and the switch in the handle, and the adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com