Wire feeding mechanism

A wire feeding mechanism and wire feeding wheel technology, applied in auxiliary devices, arc welding equipment, auxiliary welding equipment, etc., can solve the problems of complicated wire feeding wheel replacement, unstable wire feeding, economic loss, etc., and achieve good welding effect, Accurate and stable wire feeding and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

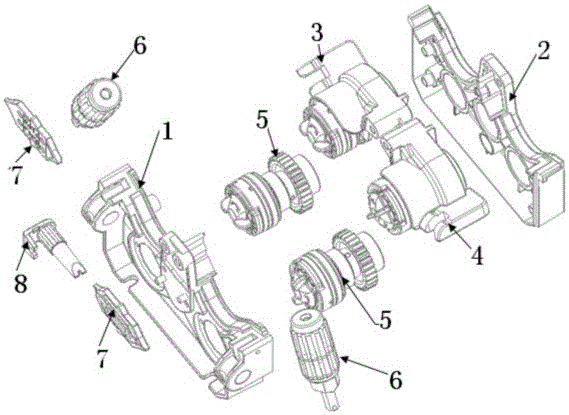

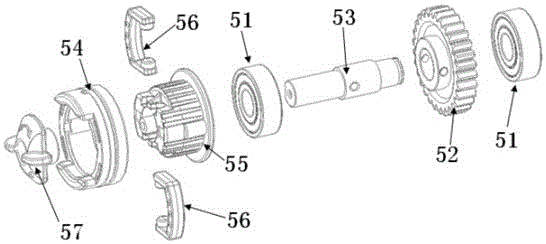

[0014] Such as figure 1 Shown is a wire feeding mechanism, including a front base 1, a rear base 2, a left pressing arm 3, a right pressing arm 4, a transmission assembly 5, a pressure adjustment assembly 6, an intermediate wire feeding module 7, and a wire feeding nozzle 8 . Such as figure 2 As shown, the transmission assembly 5 includes a precision bearing 51, a wire feeding gear 52, a finishing shaft 53, and a wire feeding wheel 54, and the wire feeding gear 52 is respectively connected to the left pressing arm 3 and the right pressing arm 4 through the precision bearing 51 , the finishing shaft 53 is connected to the wire feed wheel 54 through a fixing device, thereby driving the wire feed wheel 54 to rotate; two sets of transmission components are respectively assembled in the left pressing arm 3 and the right pressing arm 4, and the other two sets of transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com