Drum-type hook screening and impurity removal method

A trommel and trommel technology, applied in chemical instruments and methods, sieves, solids separation, etc., can solve the problems of complex structure of the screening device, affecting the screening effect, clogging of the screen, etc., to achieve sufficient kinetic energy, ensure the screening effect, Avoid blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The drum-type hook tooth screening and impurity removal method of the present invention comprises:

[0027] (1) Assembling the drum-type hook tooth screening and impurity removal equipment:

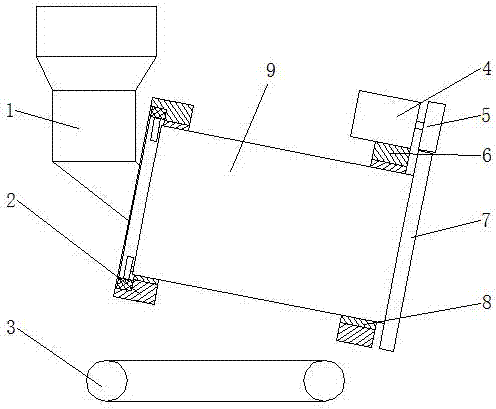

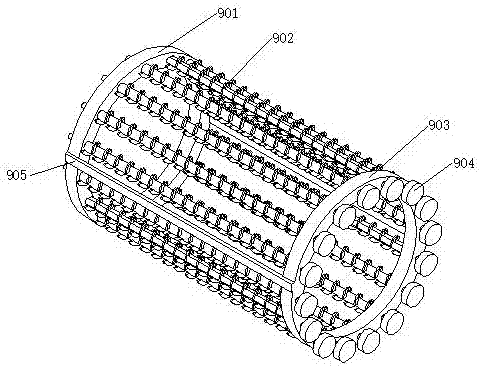

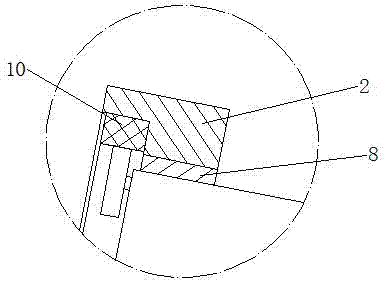

[0028] The two ends of the hook tooth shaft 902 of the drum screen 9 are installed in cooperation with the first screen frame 903 and the second screen frame 901 through sliding bearings, and a pinion 904 is added to the left end of the hook tooth shaft 902, so that the pinion 904 and the internal gear 10 Mesh installation; the internal tooth gear 10 is installed in cooperation with the left part of the inner cavity of the first support frame 2, the first support frame 2 and the second support frame are fixedly connected with the support, the first screen frame 903 at the two ends of the trommel 9 and the second screen The frame 901 is respectively connected with the first supporting frame 2 and the second supporting frame through the rolling bearing 8, and the right end of the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com