Teaching device for demonstrating all form and location tolerance detection methods

A technology of shape and position tolerance and detection method, which is applied in the direction of teaching models, educational tools, instruments, etc., can solve the problems of limited functions, expensive teaching equipment and instruments, and inconvenient carrying, so as to exercise hands-on and thinking ability and improve hands-on And the effect of thinking ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

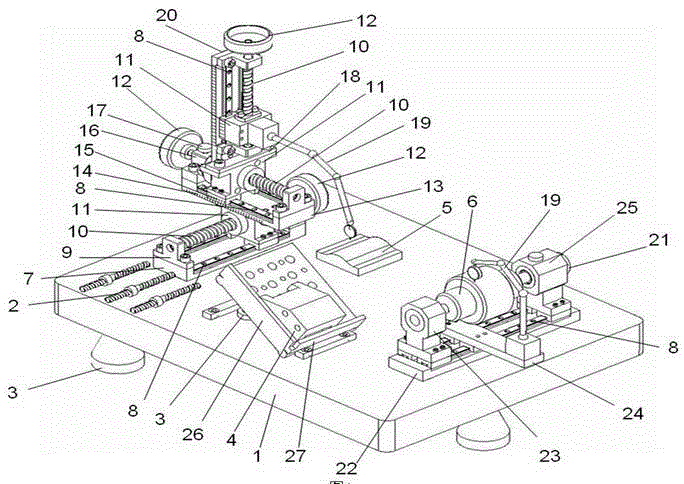

[0012] figure 1 , 2 , 3, and 4 show: one end of the double-headed left and right helical bolts 2 is installed on the bottom of the reference platform 1, and the other end is installed on the base 3 with threaded holes; the lower base 7 is fixed on the reference platform 1, and the side of the lower base 7 is engraved There is a base scale line 14 with a length of 10 cm and the smallest scale in millimeters. The two ends of the lower base 7 are fixed with a bearing seat 9 and a threaded bearing seat 16 at the top. The two ends of the screw rod 10 of the lower floor are fixed on the bearing seat 9 by bearings. And on the threaded bearing seat 16 on the top, one end of the screw mandrel 10 of the lower floor stretches out and connects the scale knob 12, and the locking bolt 17 is installed on the top of the threaded bearing seat 16 on the top, and the lower base 7 is fixed with 2 and the lower floor. The screw rod 10 is parallel to the linear guide rail 8, and the screw rod 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com