Intelligent remote cloud measurement and control system for strip shape

A technology of measurement and control system and plate shape, which is applied in general control system, control/adjustment system, program control, etc., can solve the problems of poor compatibility of hardware, large amount of communication data, and difficult replacement, so as to improve the level of automation and resist Strong interference ability and confidentiality, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

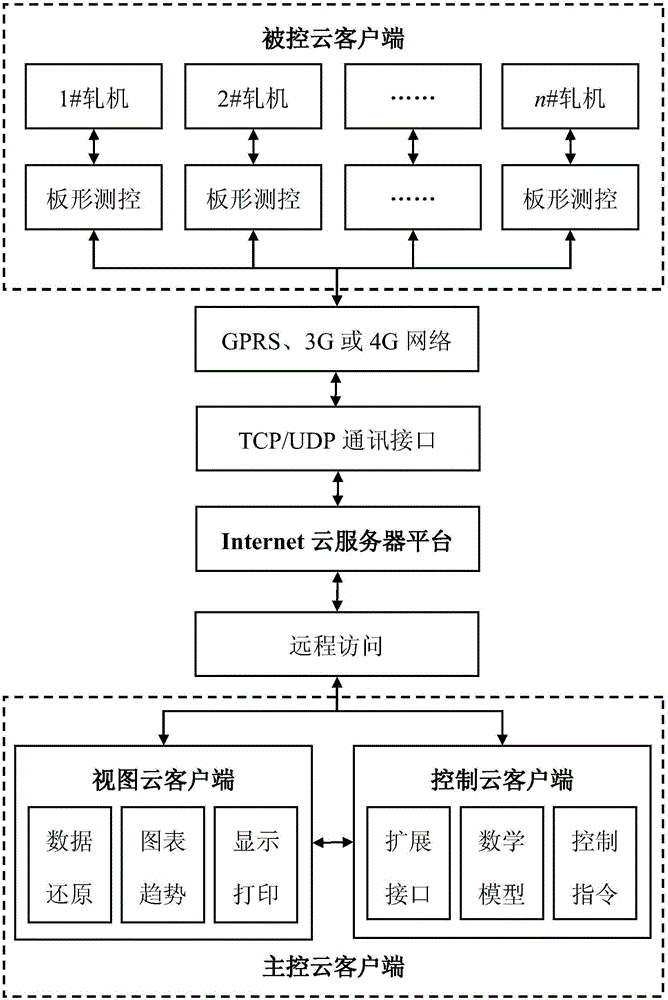

[0023] Such as figure 1 , 2 As shown, the cloud measurement and control system of the present invention includes three parts: the controlled cloud client, the cloud server platform and the master cloud client.

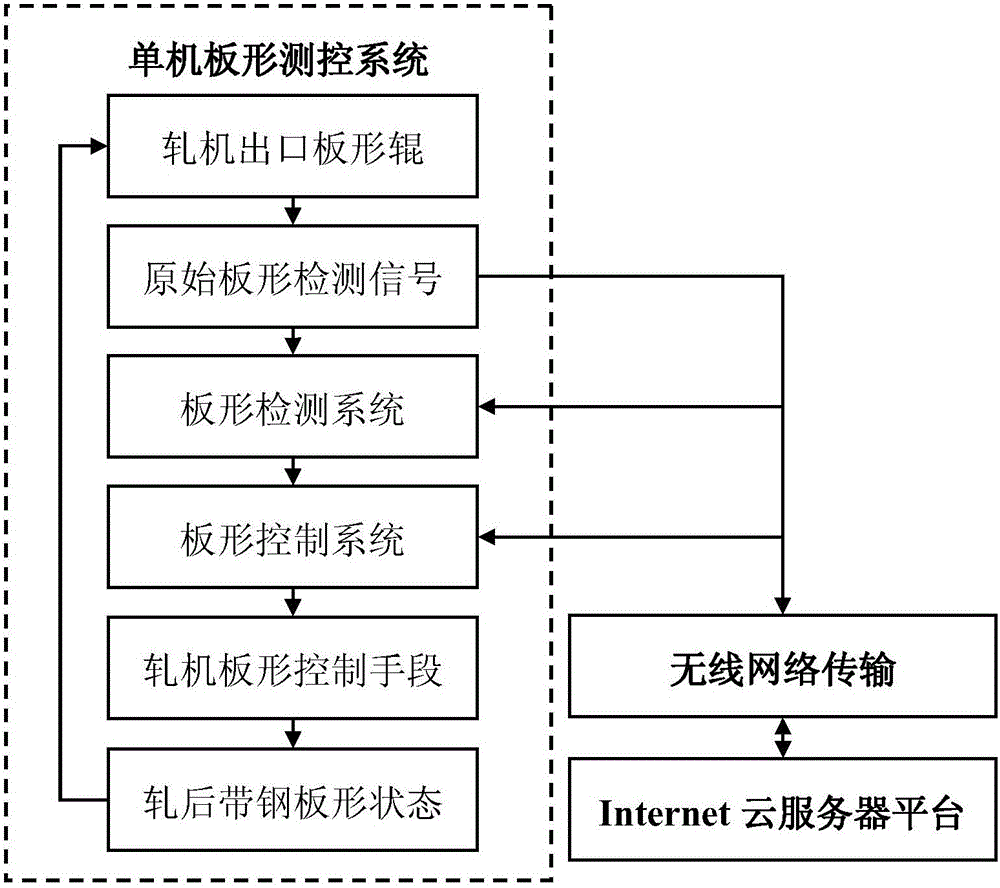

[0024] The controlled cloud client is composed of multiple single-machine flatness measurement and control systems. The single-machine flatness measurement and control system mainly consists of flatness detection rollers, flatness signal processors, flatness measurement and control cabinets (internal fixed industrial computers, switches, power boxes, etc.) and Rolling mill shape control means (tilting roll, bending roll, roll traversing and segmental cooling, etc.). The controlled cloud client serializes all the stand-alone shape measurement and control systems. The serial number is unique in the entire network for accurate identification and positioning, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com