Energy saving optimization method for grinding and grading system of mineral processing plant based on decision rule extraction

A hierarchical system and optimization method technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of increasing the difficulty of effective application, lack of rule knowledge dynamic maintenance methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

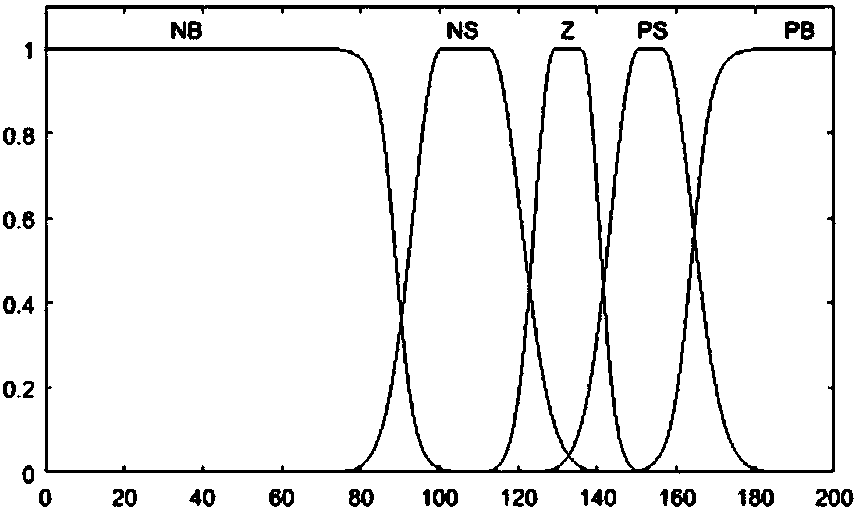

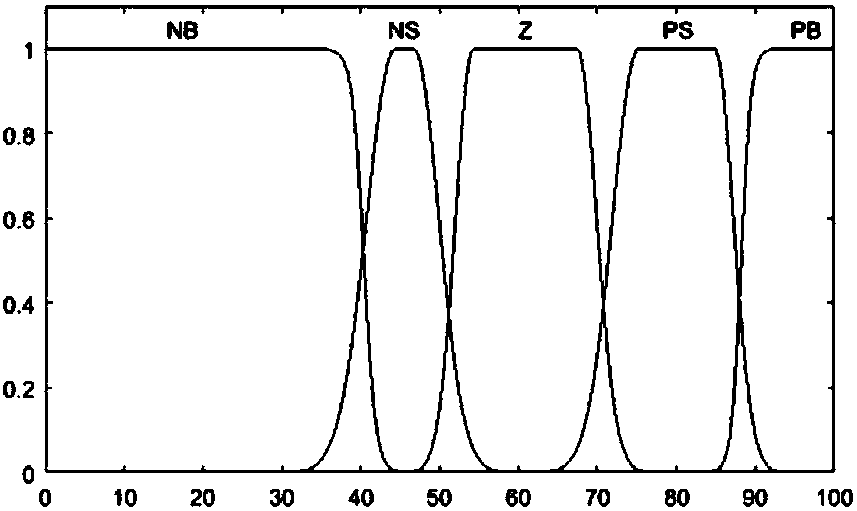

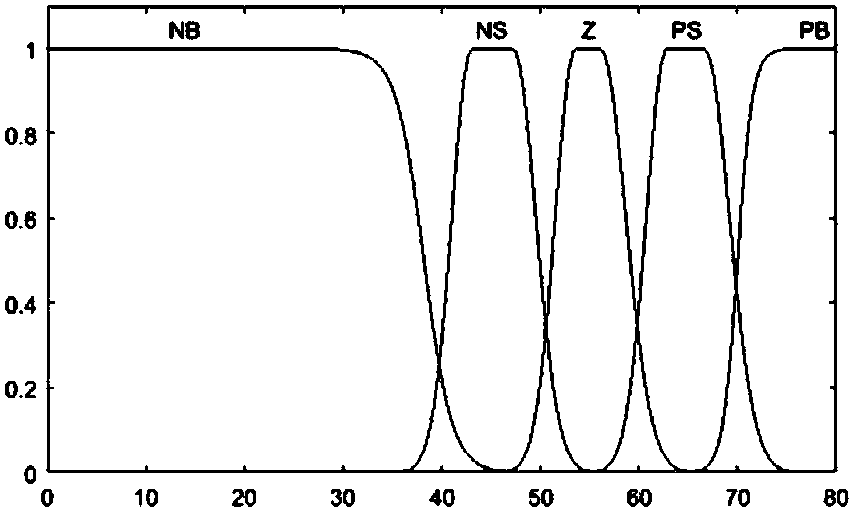

[0119] Taking the grinding and classification system of the #4 mill of a concentrator as an example, a specific application of the present invention is given. The main equipment of the grinding and grading system includes: a ball mill of model QM44Φ3.6x4.5, and a hydraulic spiral classifier of model 2FLCΦ2400x14050. Its working process is as follows: the raw ore is crushed and placed in the mine bin, the vibration feeder is controlled by the frequency converter to continuously feed the ore to the belt, and then the mineral is sent to the ball mill for grinding through the belt with an electronic scale; it is controlled by an electric regulating valve The amount of sand-returning water and ore-discharging water ensures that the mixture of ore and water is fully ground in the ball mill. The pulp discharged from the ball mill flows into the hydraulic spiral classifier for particle size classification. Fine) overflows to the next process under the action of the mine water discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com