High-voltage wire surface defect detection device

A high-voltage wire and detection device technology, applied in the field of high-voltage wire surface defect detection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

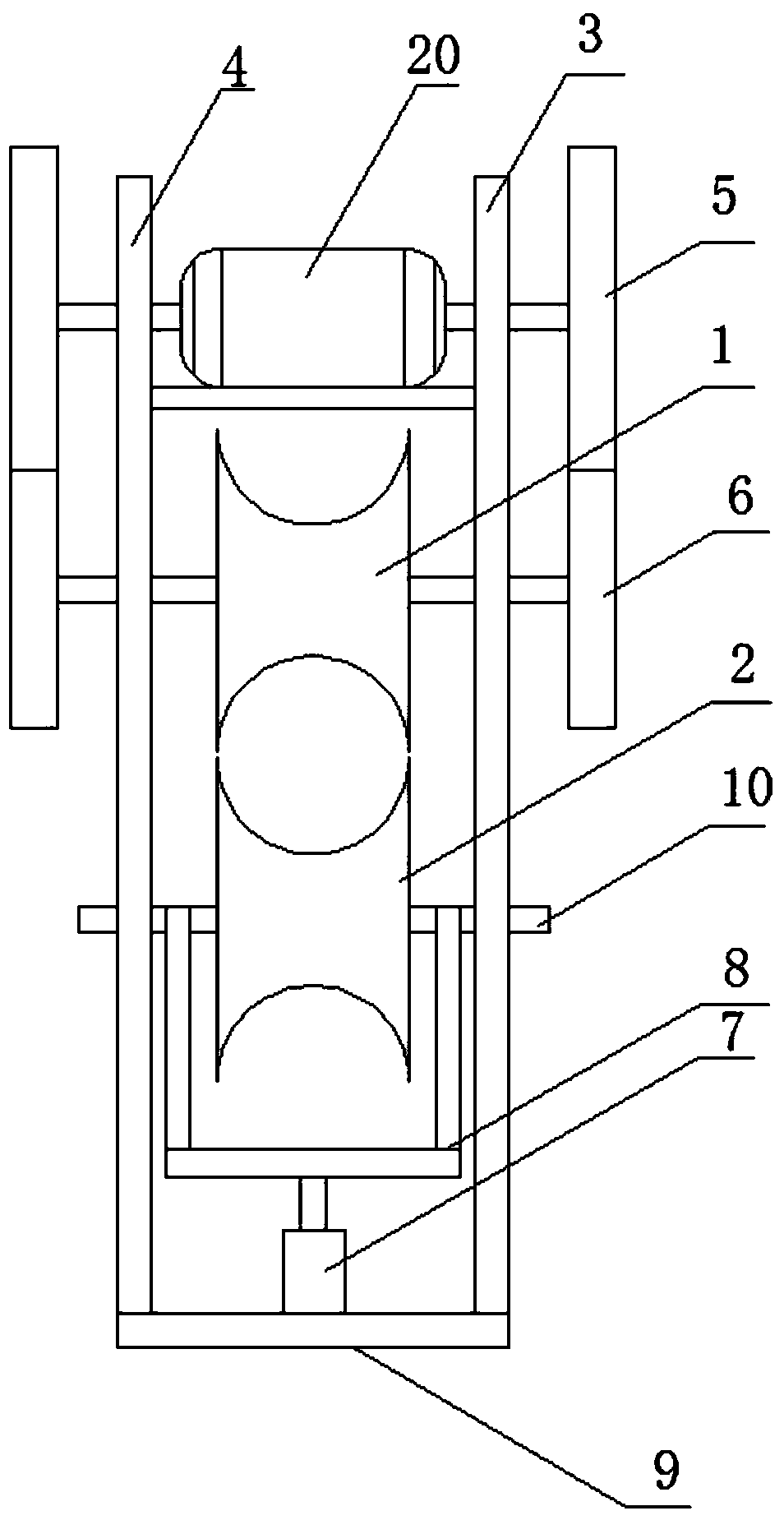

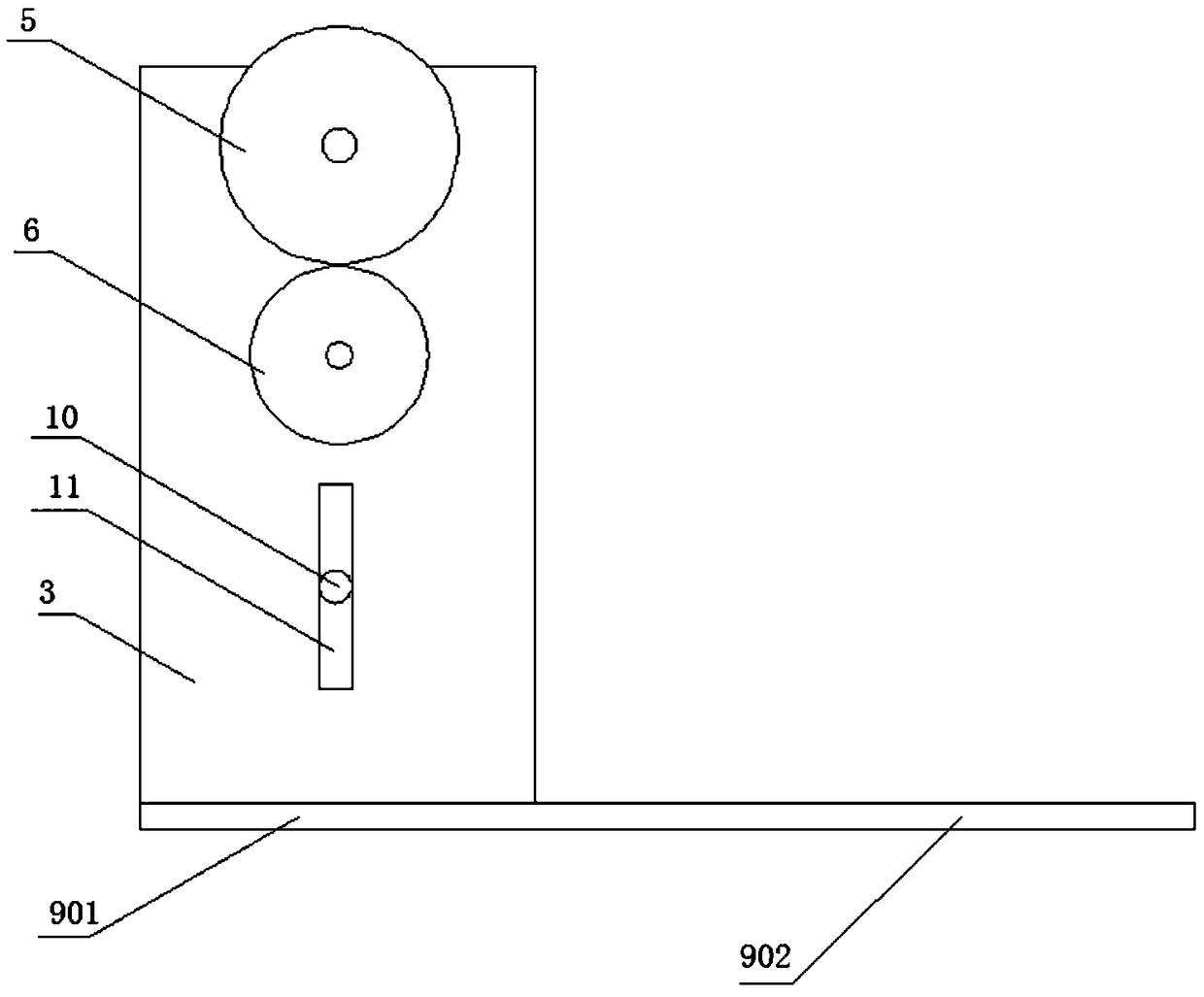

[0041] In this embodiment 1, if figure 1 , the running mechanism of the present invention is symmetrically arranged left and right, and the right side is used as an example for illustration. The traveling mechanism includes a roller set, which is composed of a first roller 1 and a second roller 2, and a gap is formed between them, and the gap is used to pass through high-voltage electric wires. The purpose is to use the first roller 1 and the second roller 2 to Squeeze the high-voltage wires, hang and fix the traveling mechanism as a whole on the high-voltage wires.

[0042] In this embodiment, in order to further optimize the extrusion and fixing effects of the first roller 1 and the second roller 2 on the high-voltage wires, see figure 1 , arc-shaped grooves are set on the extrusion peripheral surfaces of the first roller 1 and the second roller 2, so that the high-voltage wires can be partially embedded in the arc-shaped grooves, and the first roller 1 and the second rolle...

Embodiment 2

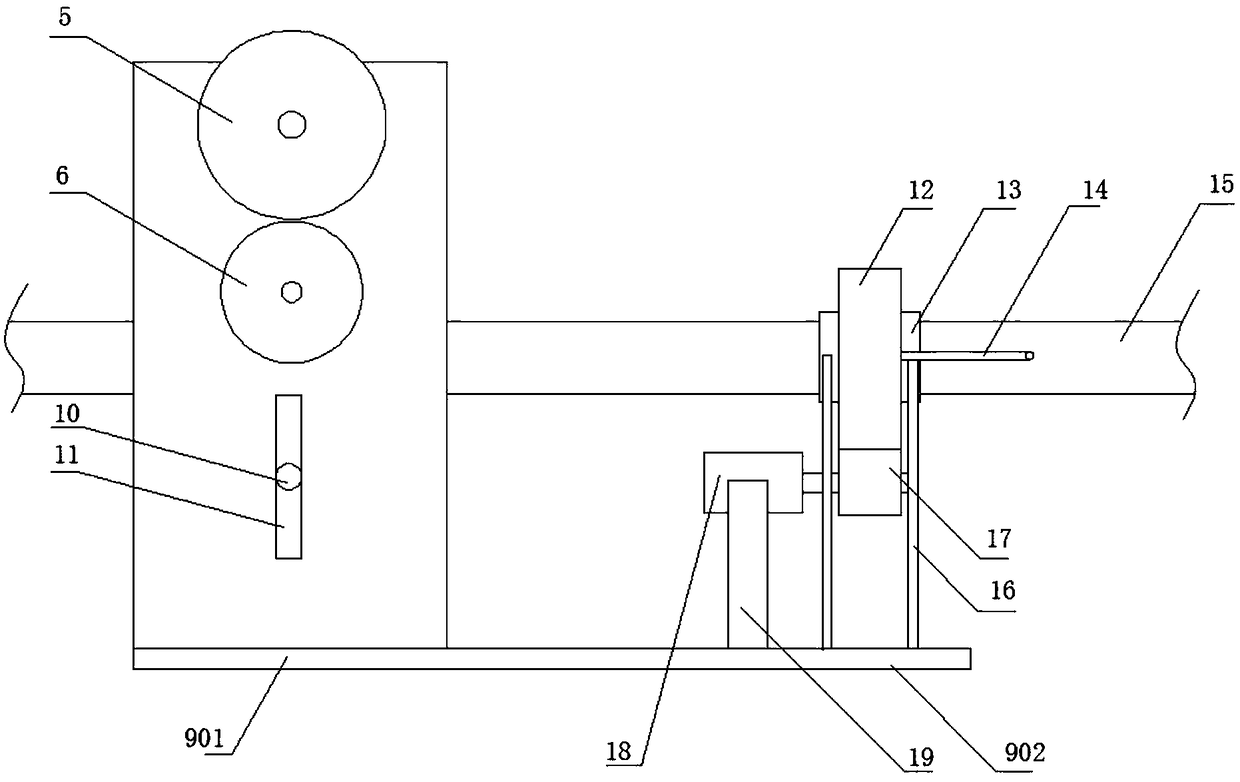

[0052] Compared with Embodiment 1, this embodiment is different in that: in this embodiment, the two main transmission wheels of the biaxial motor and the two corresponding slave transmission wheels of the first roller are transmitted through the track structure; the second power It is also driven by crawler belt structure between the running wheel 17 of the device and the outer sleeve 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com