A Method of Improving the Vibration Monitoring Accuracy of Multi-rotor Aeroengine

An aero-engine and vibration monitoring technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as large measurement errors, achieve the effects of reducing the number, increasing the amount of effective information, and avoiding spectrum leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

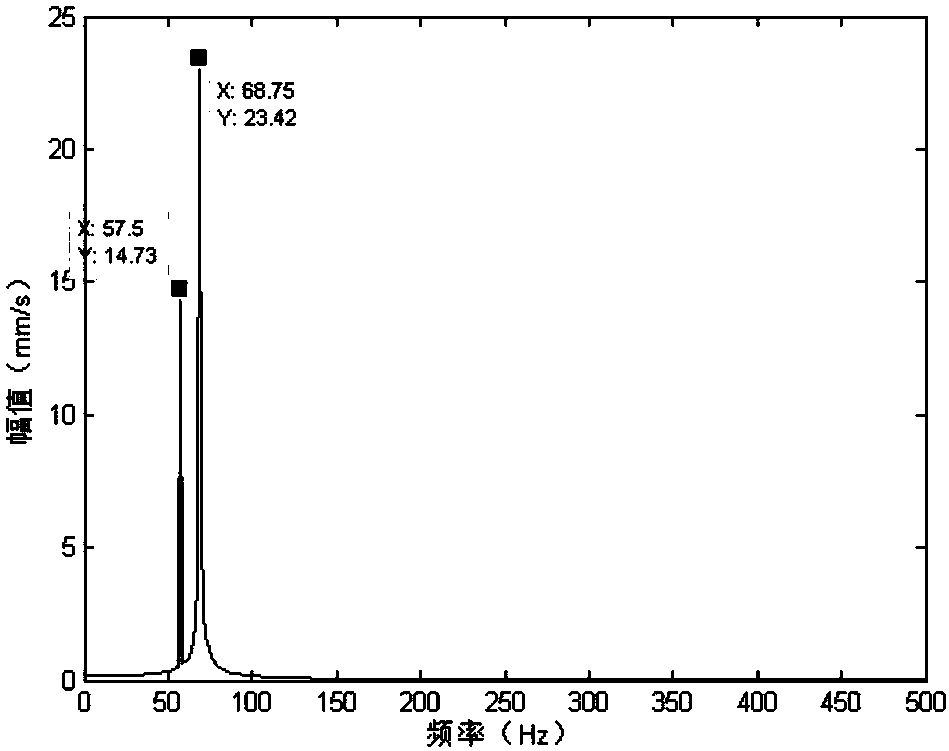

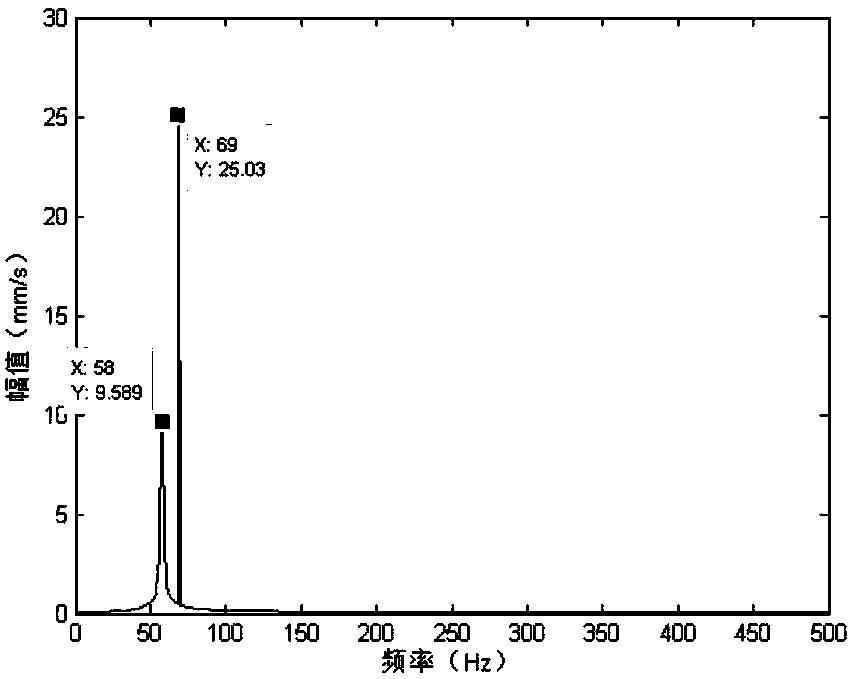

Image

Examples

Embodiment 1

[0057] This embodiment is a method for improving the vibration monitoring accuracy of a dual-rotor aeroengine, and the specific process is:

[0058] Step 1, collect the rotational speed of each rotor of the engine. Acquisition based on onboard sensor signals.

[0059] For a dual-rotor engine, the high-pressure rotor speed n of the engine is collected at the same time 2 and low pressure rotor speed n 1 .

[0060] Step 2: Determine the sampling frequency of the vibration signal according to the structural parameters of the engine.

[0061] According to formula (1), the sampling frequency f of the vibration signal is determined by two parameters, namely the reference rotor rotation frequency f 0 and the number of sampling points per cycle 2 Z .

[0062] Among them, the reference rotor rotation frequency f 0 Determined by formula (2):

[0063] f=2 Z f 0 (1)

[0064] The reference rotor selects the rotor with the highest rotational speed among the rotors of the engine. ...

Embodiment 2

[0090] This embodiment is a method for improving the vibration monitoring accuracy of a three-rotor aero-engine, and the specific process is:

[0091] Step 1, collect the rotational speed of each rotor of the engine. Acquisition based on onboard sensor signals.

[0092] For a three-rotor engine, the high-pressure rotor speed n of the engine is collected at the same time 3 , Medium pressure rotor speed n 2 and low pressure rotor speed n 1 . The unit of each rotor speed is rev / min.

[0093] Step 2: Determine the sampling frequency of the vibration signal according to the structural parameters of the engine.

[0094] According to formula (1), the sampling frequency f of the vibration signal is determined by two parameters, namely the reference rotor rotation frequency f 0 and the number of sampling points per cycle 2 Z .

[0095] f=2 Z f 0 (1)

[0096] The reference rotor selects the rotor with the highest rotational speed among the rotors of the engine. Using equati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com