Pipeline plugging device with resonance switch

An occluder and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of resistance in the recovery process and the lack of strict blocking of pipeline occluders, so as to reduce resistance and safety. High and reduced risk of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

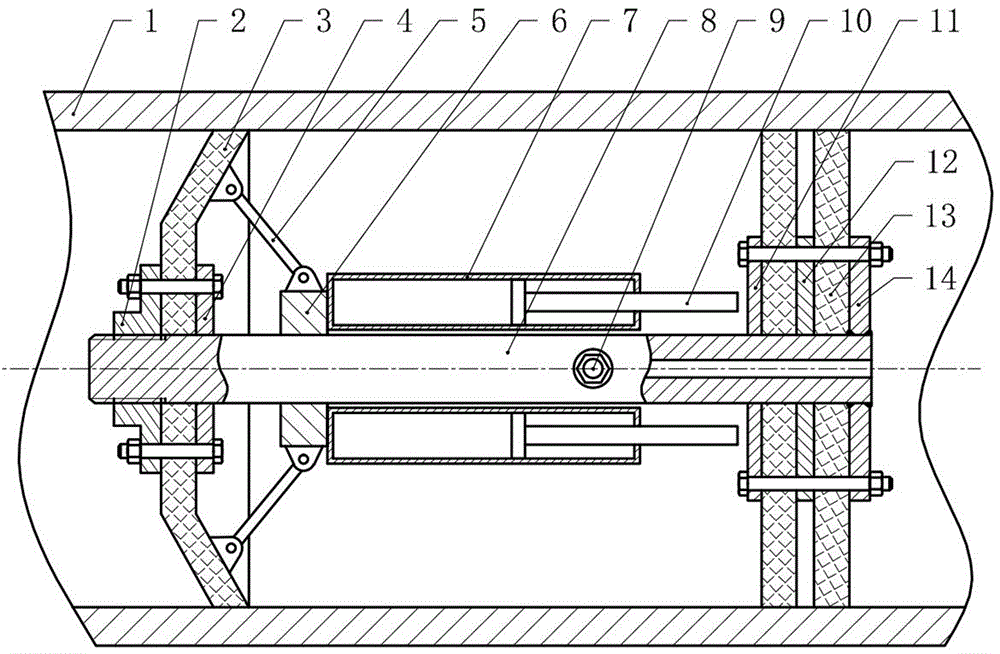

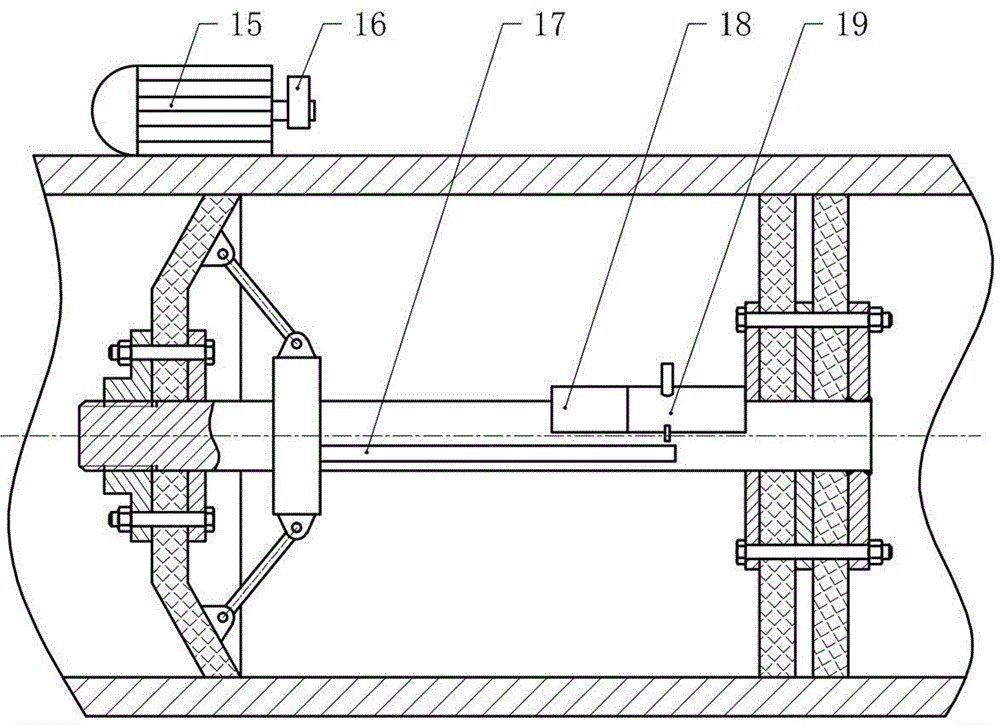

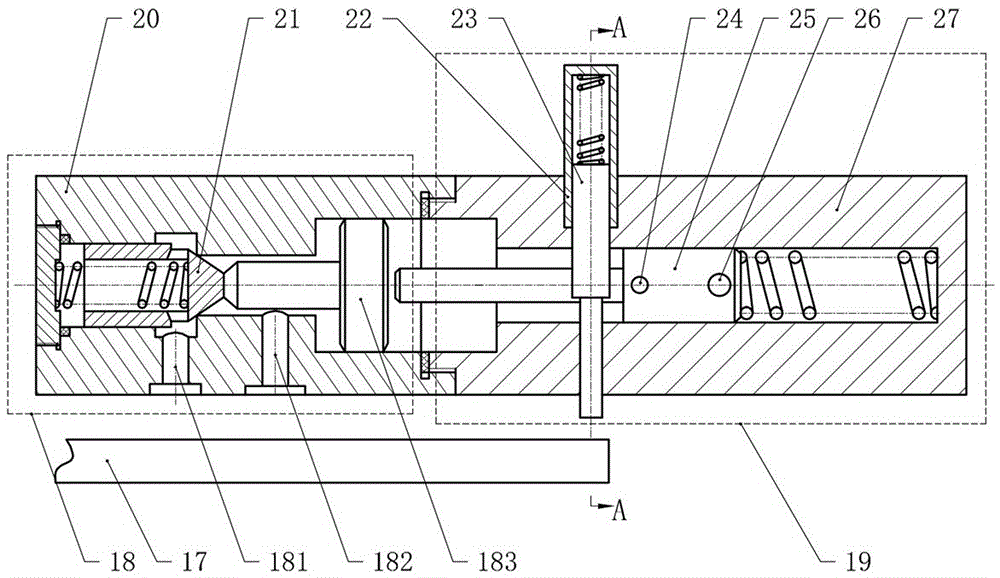

[0022] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below Figure 1~6 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0023] The front cup 3 is dish-shaped with a central hole. The front end cover 2 is installed on the front end of the mandrel 8 and connected with threads. The front cup 3 is pressed on the front cover 2 through the front mounting ring 4 and the front cover 2 and the front mounting ring are connected by bolts. 4. The rear end of the mandrel 8 is installed with a rear end cover 14 and fixed by welding. The rear cups 13 are circular, and the two rear cups 13 are pressed on the rear end cover 14 through the rear mounting ring 11 and the rear end cover 14 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com