A shaft assembly device for a front-wheel-drive automobile transmission assembly

A technology for automotive transmissions and assembling devices, which is applied to transmission parts, components with teeth, belts/chains/gears, etc. It can solve problems such as poor surface quality, damage to oil seals, time-consuming and labor-intensive problems, and achieve the effect of ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

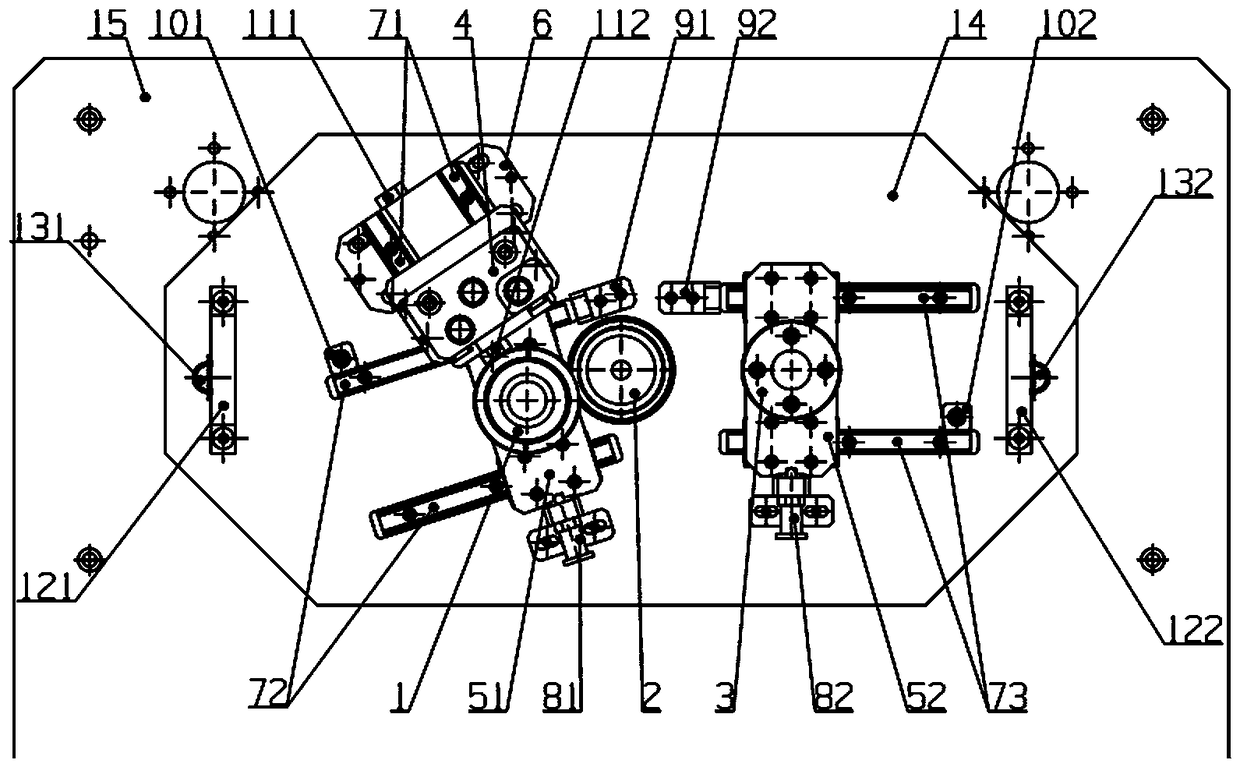

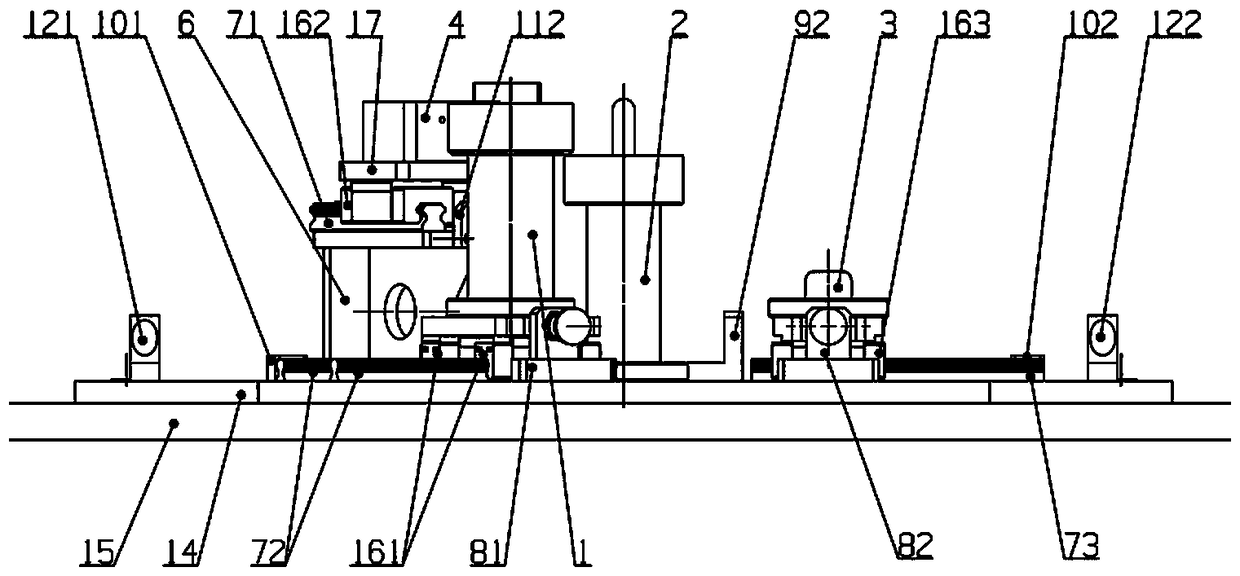

[0021] see figure 1 and figure 2 , the shaft assembly device of the front-wheel-drive automobile transmission assembly of the present invention includes an input shaft positioning part 1, an intermediate shaft positioning part 2, a differential positioning part 3, a shift fork shaft positioning part 4, a first support block 51, a second Two support blocks 52, left and right support frames 6, the first pair of guide rails 71, the second pair of guide rails 72, the third pair of guide rails 73, the first locking device 81, the second locking device 82, the first long limit block 91, The second long limiter 92, the first short limiter 101, the second short limiter 102, the first stopper 111, the second stopper 112, the bottom plate 14, the mounting plate 15, the first pair of sliders 161, The second pair of sliders 162 , the third pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com