Silencer assembly and compressor

A muffler and compressor technology, which is applied in the field of compressors, can solve the problems such as the limited noise reduction effect of the muffler, and achieve the effect of improving the noise reduction effect and increasing the baffle path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

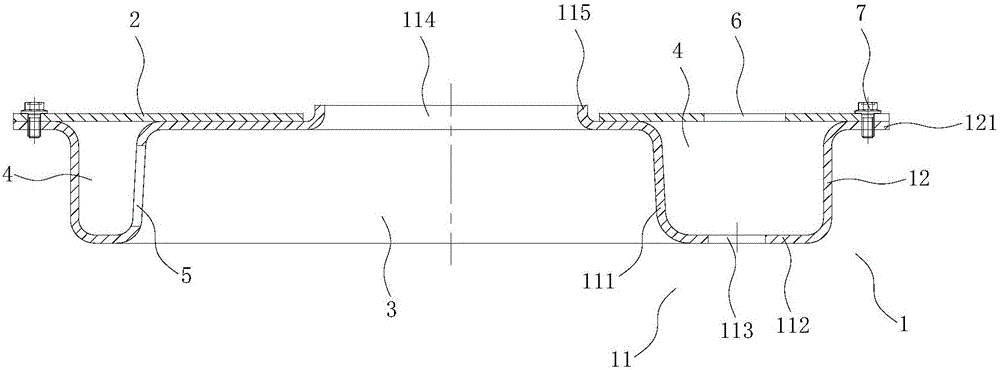

[0027] This embodiment provides a muffler assembly 10, such as figure 2 As shown, the muffler assembly 10 includes a muffler 1 and a cover plate 2, wherein the muffler 1 includes a raised portion 11 and a skirt 12 surrounding the raised portion 11 in the circumferential direction, and the cover plate 2 is fixed on the skirt 12 , and the first chamber 4 is formed between the above-mentioned cover plate 2, the raised portion 11 and the skirt 12, the raised portion 11 is provided with an opening-shaped chamber 3, and the raised portion 11 is provided with At least one exhaust hole 5 communicates with the chamber 3 and the first chamber 4 , and at least one exhaust port 6 communicated with the first chamber 4 is provided on the cover plate 2 . After the gas passes through the chamber 3, it will flow into the first chamber 4 through the exhaust hole 5, and then be discharged from the first chamber 4 through the exhaust port 6. Circulation, the baffle path of the gas has been incr...

Embodiment 2

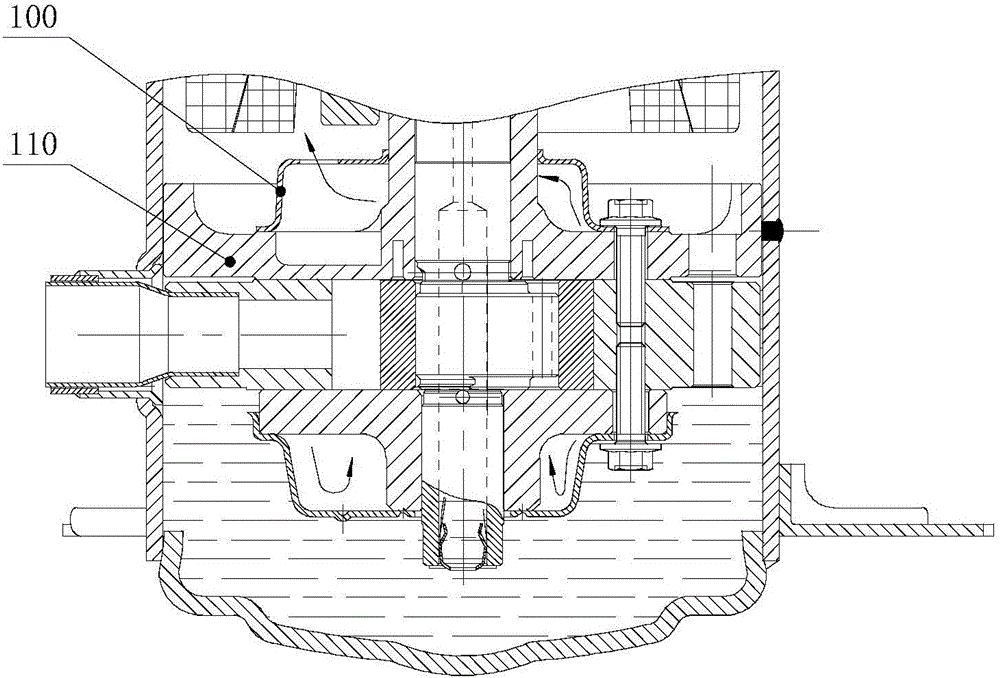

[0037] This embodiment provides a compressor, which may be a rolling rotor compressor in this embodiment, such as Image 6 As shown, the compressor includes the muffler assembly 10 described in Embodiment 1, and the upper flange 20 affixed to the muffler assembly, the muffler 1 of the above muffler assembly 10 and the upper flange 20 form a The second chamber 30, specifically the opening-shaped chamber 3 on the raised portion 11 and the upper flange 20 jointly form the second chamber 30, the second chamber 30 and the first chamber 4 pass through the exhaust hole 5 connected. The compressed gas produced by the compressor first enters the second chamber 30 , then flows into the first chamber 4 through the exhaust hole 5 , and then flows into the lower cavity of the motor through the exhaust port 6 on the cover plate 2 . Through the above-mentioned muffler assembly 10, the exhaust noise of the compressor can be effectively reduced, and the newly added first chamber 4 of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com