A highly adaptable sound-absorbing and shock-absorbing automobile exhaust pipe bracket

An automobile exhaust and adaptability technology, which is applied in the field of auto parts, can solve the problems of wasting resources, increasing costs, and poor adaptability, and achieves the effects of reducing fuel consumption, reducing weight, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

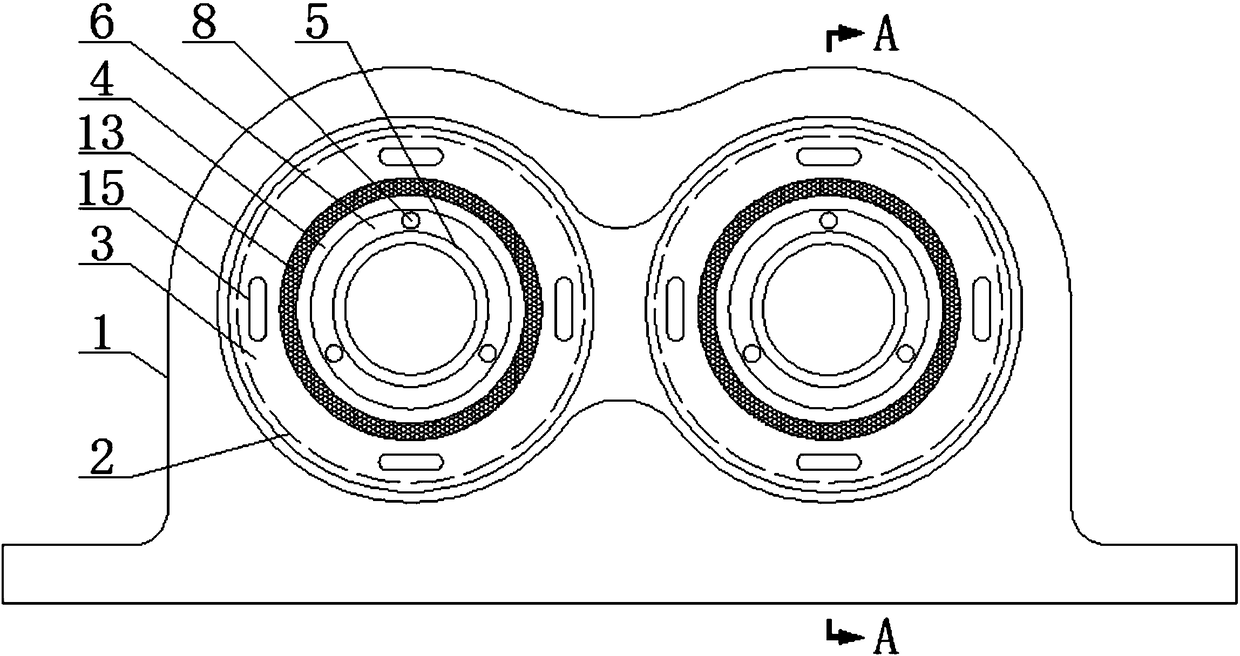

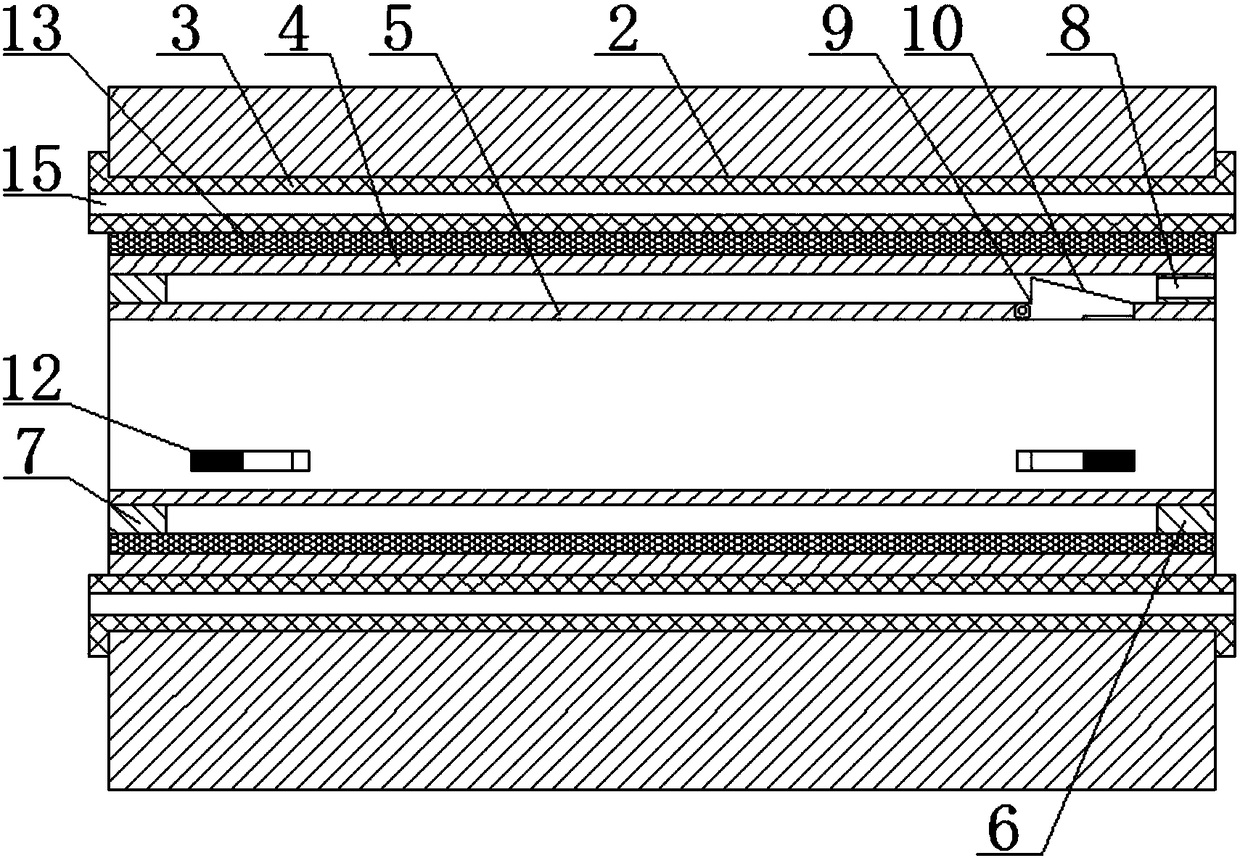

[0027] Such as Figure 1 to Figure 5 As shown, a high-adaptability sound-absorbing and shock-absorbing automobile exhaust pipe bracket includes a bracket body 1, and the bracket body 1 is provided with two installation holes 2, and the axes of the two installation holes 2 are parallel to each other. The mounting holes 2 of each are provided with a connecting sleeve, and a rubber layer 3 is provided between the connecting sleeve and the mounting hole 2. The connecting sleeve includes an outer tube 4 and an inner tube 5 with a diameter of one large and a small one, and a welded seal on the outside. The front cover 6 and the back cover 7 at both ends of the tube 4 and the inner tube 5 are circular in shape and connected between the outer tube 4 and the inner tube 5. The front cover 6 is provided with several threaded holes 8. A pressing device is provided on the inner tube 5 close to the front cover 6. The pressing device includes a rectangular through-hole 9 arranged on the inne...

Embodiment 2

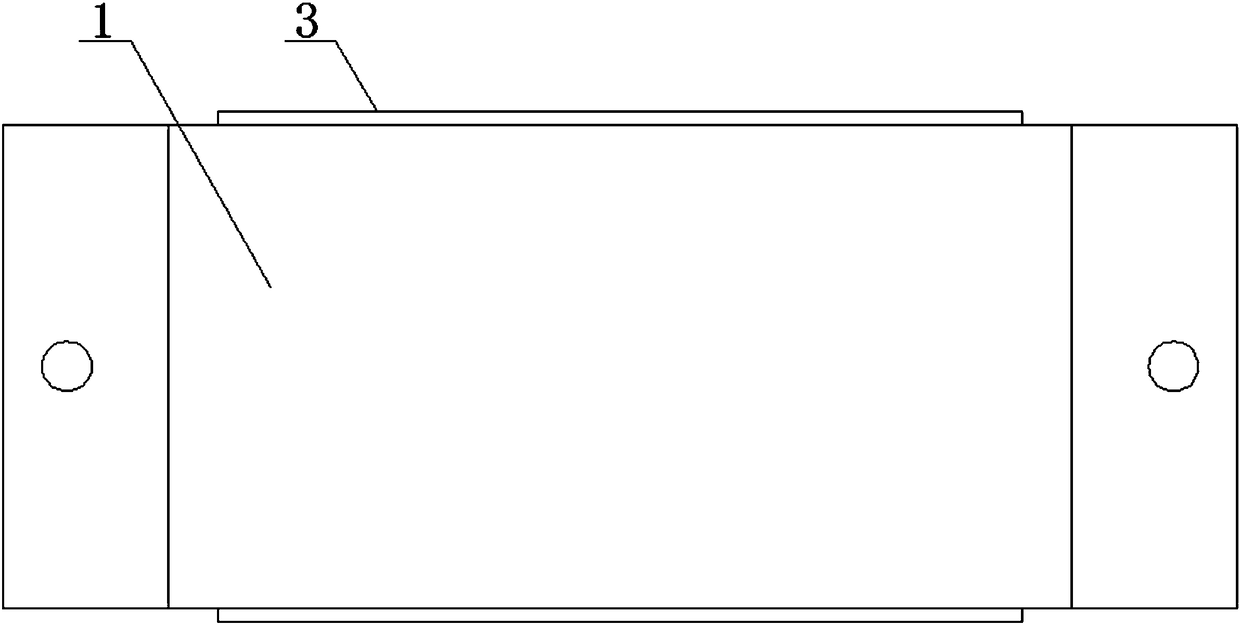

[0034] Such as Figure 6 to Figure 8 As shown, a high-adaptability sound-absorbing and shock-absorbing automobile exhaust pipe bracket includes a bracket body 1, and the bracket body 1 is provided with two installation holes 2, and the axes of the two installation holes 2 are parallel to each other. The mounting holes 2 of each are provided with a connecting sleeve, and a rubber layer 3 is provided between the connecting sleeve and the mounting hole 2. The connecting sleeve includes an outer tube 4 and an inner tube 5 with a diameter of one large and a small one, and a welded seal on the outside. The front cover 6 and the back cover 7 at both ends of the tube 4 and the inner tube 5 are circular in shape and connected between the outer tube 4 and the inner tube 5. The front cover 6 is provided with several threaded holes 8. A pressing device is provided on the inner tube 5 close to the front cover 6. The pressing device includes a rectangular through-hole 9 arranged on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com