High-suitability sound absorbing and damping automobile exhaust pipe support

A technology for automobile exhaust and adaptability, applied in the field of auto parts, can solve problems such as increased cost, waste of resources, poor adaptability, etc., and achieve the effect of reducing fuel consumption, weight, and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

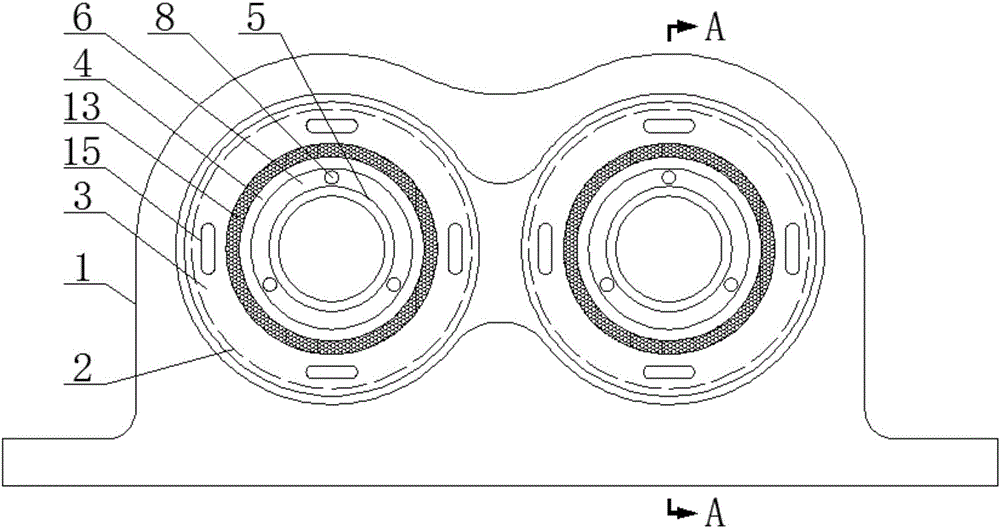

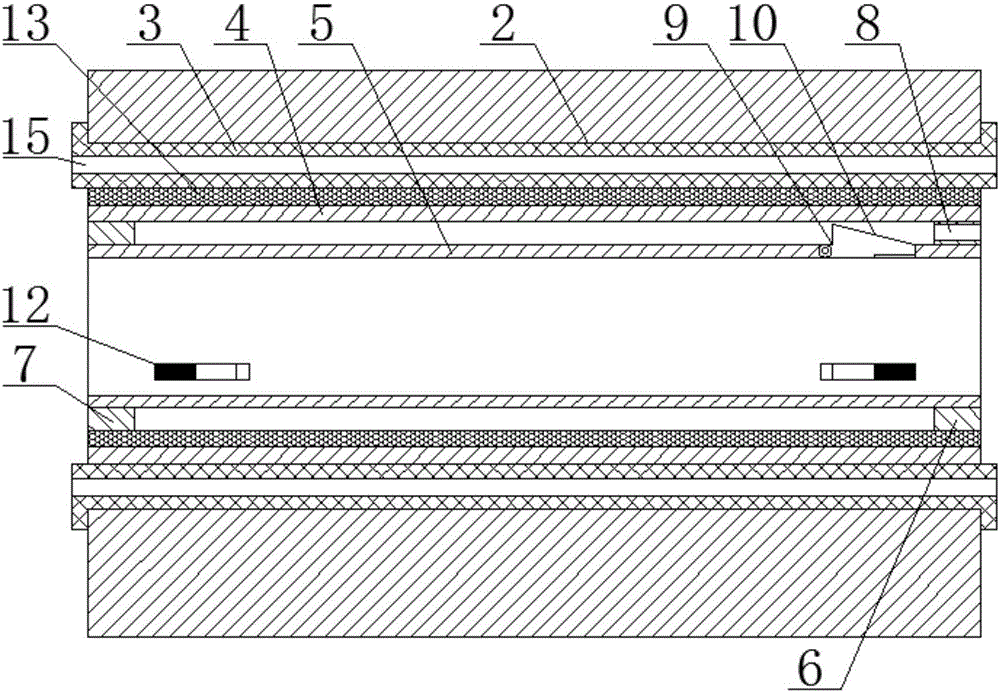

[0027] like Figure 1 to Figure 5 As shown in the figure, an automobile exhaust pipe bracket with high adaptability for sound absorption and shock absorption includes a bracket body 1. The bracket body 1 is provided with two mounting holes 2, and the axes of the two mounting holes 2 are parallel to each other. The mounting holes 2 are provided with connecting sleeves, and a rubber layer 3 is arranged between the connecting sleeves and the mounting holes 2. The connecting sleeves include an outer tube 4 and an inner tube 5 with a larger diameter and a smaller diameter, and are welded and sealed on the outside. The front cover 6 and the rear cover 7 at both ends of the tube 4 and the inner tube 5, the shape of the front cover 6 and the rear cover 7 are annular and connected between the outer tube 4 and the inner tube 5, and the front cover 6 is provided with a number of threaded holes 8. A pressing device is provided on the inner tube 5 near the front cover 6. The pressing devic...

Embodiment 2

[0034] like Figures 6 to 8 As shown in the figure, an automobile exhaust pipe bracket with high adaptability for sound absorption and shock absorption includes a bracket body 1. The bracket body 1 is provided with two mounting holes 2, and the axes of the two mounting holes 2 are parallel to each other. The mounting holes 2 are provided with connecting sleeves, and a rubber layer 3 is arranged between the connecting sleeves and the mounting holes 2. The connecting sleeves include an outer tube 4 and an inner tube 5 with a larger diameter and a smaller diameter, and are welded and sealed on the outside. The front cover 6 and the rear cover 7 at both ends of the tube 4 and the inner tube 5, the shape of the front cover 6 and the rear cover 7 are annular and connected between the outer tube 4 and the inner tube 5, and the front cover 6 is provided with a number of threaded holes 8. A pressing device is provided on the inner tube 5 near the front cover 6. The pressing device incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com