Novel long spiral drilling hole cast-in-situ pile top and cap integrated construction device

A technology of long auger drilling and construction device, which is applied to drill pipes, drill pipes, sheet pile walls, etc., can solve the problems of overall structural instability, low efficiency of long auger drilling rigs, and reduce production costs, and achieve overall structural design. Reasonable, save raw materials and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

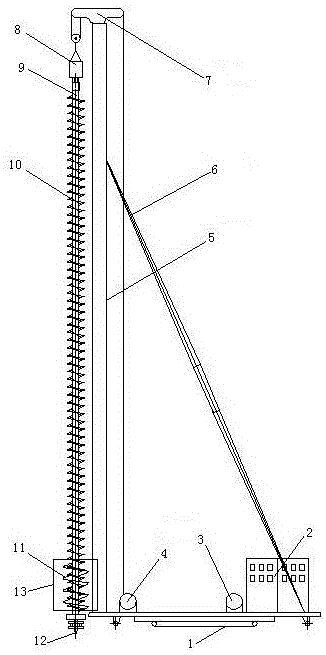

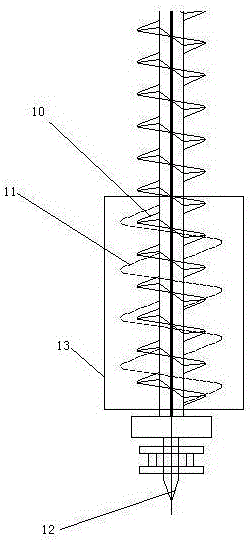

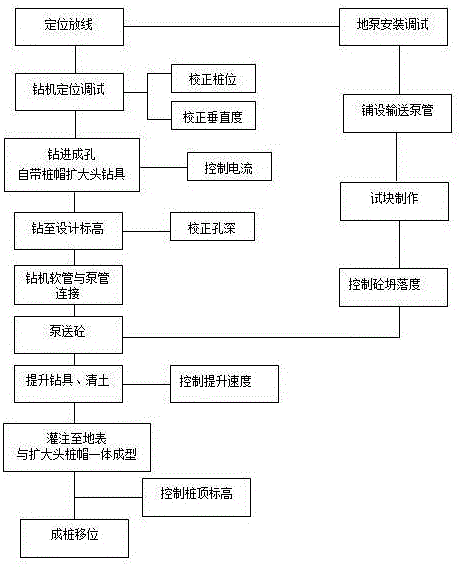

[0019] further as figure 1 , figure 2 and image 3 As shown, when the alloy drill bit 12 is drilled in the drilling and pouring construction, the drill bit is equipped with an expanding head drilling tool (the expanding head drilling tool is not marked in the figure), (the diameter of the pile can be 80cm, or 1m, depending on the diameter of the pile cap at the construction site The depth of the expansion head drilling tool is generally 60cm. After the expansion head part enters the soil layer of 60cm, it can automatically break away from the drill pipe, and the expansion head drilling tool stays at the position of the 60cm deep soil layer, so that the drill pipe continues to drill to the designed pile length position, lift the concrete, lift the drill pipe to the top 60cm position, and then lift it up with the drill tool of the expansion head, and make the 1m diameter of the drill tool of the expansion head be filled with concrete together to make it reach the concrete of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com