Ultrasonic washing tub and washed woven belt production line

A water washing bucket and ultrasonic technology, applied in the field of webbing manufacturing, can solve the problems of dirty oil stains on the webbing surface, and the cleaning effect needs to be improved, so as to achieve the effect of thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

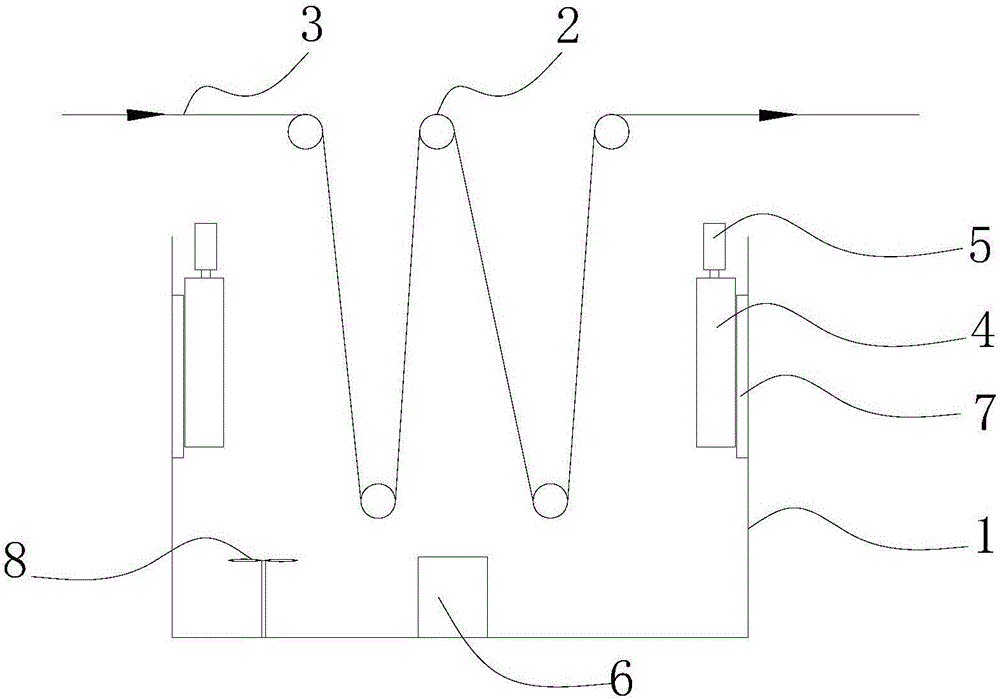

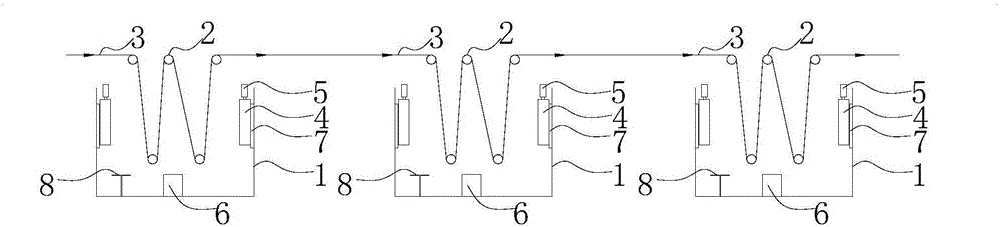

[0021] Combine below figure 1 , figure 2 The technical solutions of the present invention are further explained through specific implementations.

[0022] First of all, it should be noted that the "top", "bottom", "up", "down", "left", and "right" used in the present invention refer to the page view and should not be construed as protecting Limits of scope.

[0023] Such as figure 1 As shown, an ultrasonic washing bucket of the present invention includes a washing bucket 1. A number of transmission rollers 2 are arranged inside the washing bucket 1. The transmission rollers 2 are arranged up and down in rows. The transmission rollers 2 in the lower row are immersed in water, and the upper row is The transmission roller 2 and the lower row of transmission rollers 2 are arranged staggered. The webbing 3 goes around the drive roll 2 from left to right and is immersed in water and then output after cleaning, so that the webbing 3 is immersed in the heated water; among them, explained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com