Environment-friendly recyclable degradable paper material and preparation method thereof

A paper-made, environmentally friendly technology, applied in the field of paper materials, can solve the problem of not forming a system, reduce waste, meet the requirements of direct recycling and strength performance, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

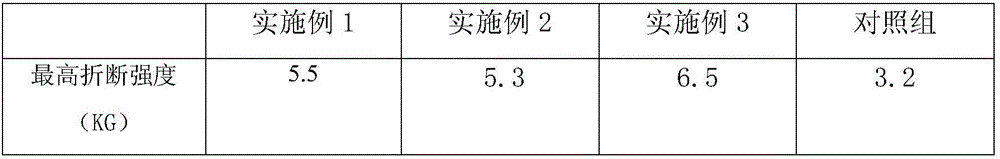

Examples

Embodiment 1

[0028] An environmentally friendly recyclable degradable paper material, the environmentally friendly recyclable degradable paper material is made by mixing gelatinized starch glue with a mass fraction of 20% and 80% paper powder, wherein the gelatinized starch glue includes Tapioca starch, starch modifier, wetting agent, reinforcing agent, polyvinyl alcohol, wherein, the mass fraction of each component is 30% of tapioca starch, 1% of starch modifying agent, 2% of wetting agent, 30% of reinforcing agent, polyvinyl alcohol Vinyl alcohol 37%.

[0029] The specific production steps of the above-mentioned environmentally friendly recyclable degradable paper material preparation method are as follows:

[0030] 1). Preparation of gelatinized starch glue

[0031] Tapioca starch, starch modifier, wetting agent, reinforcing agent, polyvinyl alcohol are according to mass fraction: 30% of tapioca starch, 1% of starch modifying agent, 2% of wetting agent, 7% of reinforcing agent, 60% of ...

Embodiment 2

[0037] An environmentally friendly, recyclable and degradable paper material, made of a mixture of 40% gelatinized starch glue and 60% paper powder; the gelatinized starch glue includes tapioca starch, starch modifier, and wetting agent , reinforcing agent, polyvinyl alcohol, wherein, the mass fraction of each component is 60% of tapioca starch, 2% of starch modifier, 5% of wetting agent, 3% of reinforcing agent, 30% of polyvinyl alcohol.

[0038] The specific production steps of the above-mentioned environmentally friendly recyclable degradable paper material preparation method are as follows:

[0039] 1). Preparation of gelatinized starch glue

[0040] Tapioca starch, starch modifier, wetting agent, reinforcing agent, polyvinyl alcohol are according to mass fraction: tapioca starch 48%, starch modifying agent 2%, wetting agent 5%, reinforcing agent 15%, polyvinyl alcohol 30% Proportionally put into the reactor, stir after adding water, start the reactor and stir until there...

Embodiment 3

[0046] An environmentally friendly, recyclable and degradable paper material, made of a mixture of 50% gelatinized starch glue and 50% paper powder; the gelatinized starch glue includes tapioca starch, starch modifier, and wetting agent , reinforcing agent, polyvinyl alcohol, wherein, the mass fraction of each component is 48% of tapioca starch, 2% of starch modifier, 5% of wetting agent, 15% of reinforcing agent, 30% of polyvinyl alcohol.

[0047] The starch modifier is a degradable polycaprolactone macromolecule, and the starch-based polyurethane (St-PCL) is prepared by introducing the degradable polycaprolactone (PCL) macromolecule into the backbone of the starch molecule and capping it with HDI. To a certain extent, the hydrophobicity and water resistance of starch-based materials are improved. At the same time, St-PCL, as a compatibilizer of the St / PCL blend system, can effectively improve the adhesion between the starch phase and the PCL phase interface and the compatibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com