Optimal dispatching method for warehousing systems combining rail guided vehicles and lifts

A warehousing system and optimized scheduling technology, applied in transportation, packaging, storage devices, etc., to achieve high utilization, optimized scheduling, and shortened access travel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

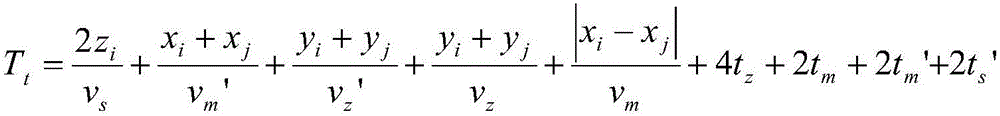

[0026] The present invention provides a mixed optimal dispatching method for a shuttle car and an elevator, which is specifically implemented according to the following steps:

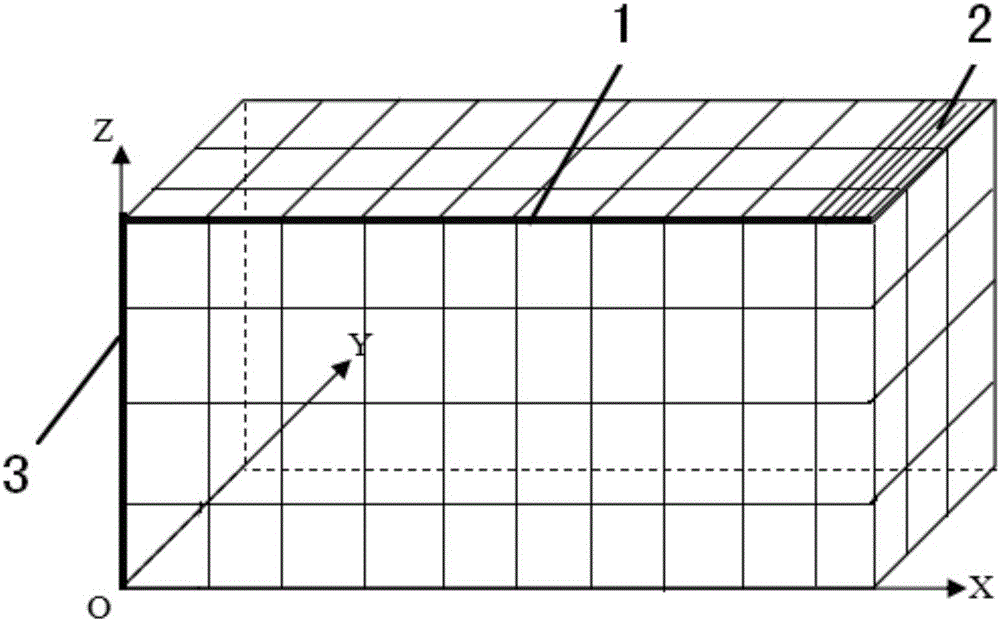

[0027] Step 1 establishes a reasonable mathematical model for the dispatching situation of an elevator with a set of shuttle car (1:1 type);

[0028] 1.1 Analyze and study the fully automatic three-dimensional warehouse of the shuttle bus, and formulate the rules for cargo storage and withdrawal

[0029] see figure 1 , The fully automatic three-dimensional warehouse of the shuttle car includes: the shuttle car (composed of the child car and the mother car), the mother car walking track (roadway), the child car walking track (shelf row), the shuttle shelf, the pallet vertical lifting system ( Lift), pallet conveying system, CMS equipment control system, WMS warehouse manageme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com