Pipe expander for condenser

A condenser and tube expander technology, applied in heat exchange equipment, metal processing equipment, feeding devices, etc., can solve the problems of unguaranteed accuracy, low production efficiency, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

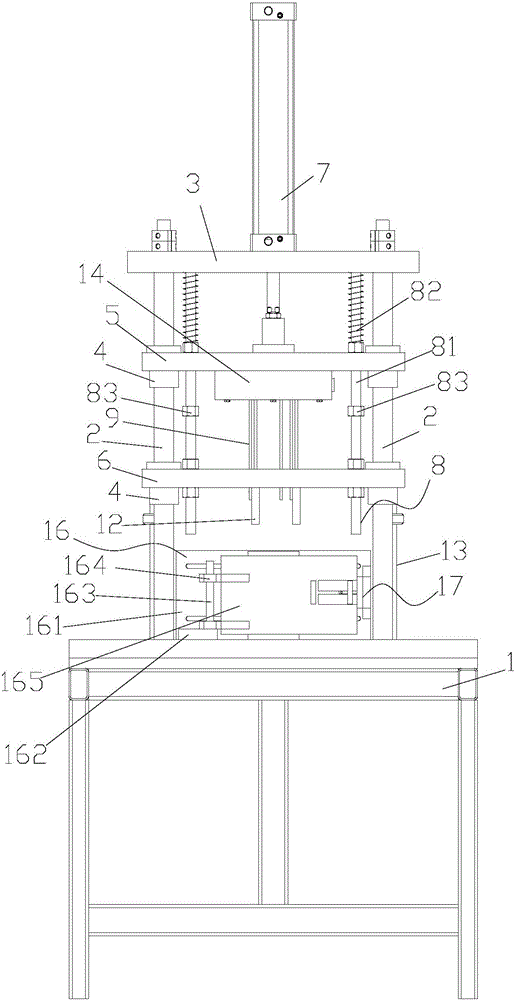

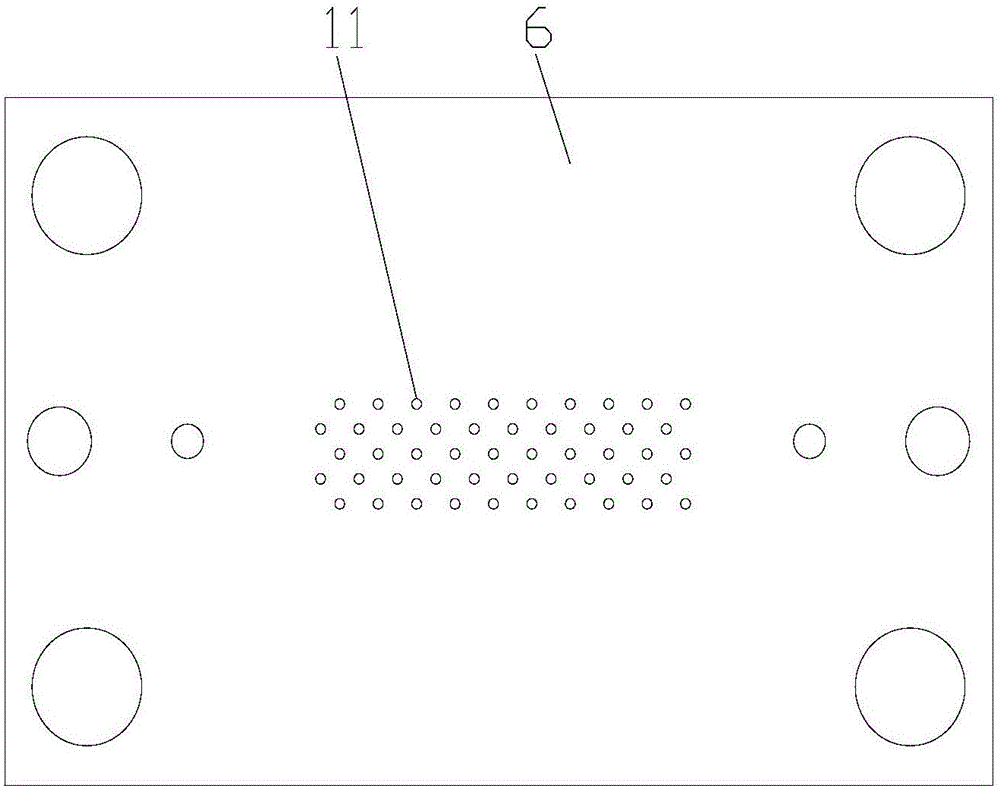

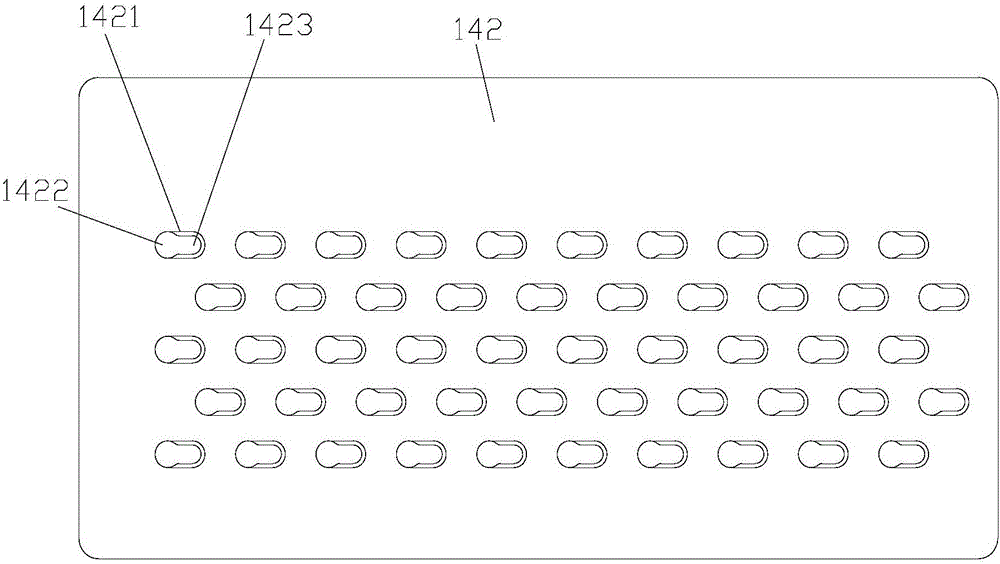

[0028] Example 1, such as Figure 1 to Figure 9 , a tube expander for condensers, including a frame 1, four fixed rods 2 are installed on the frame 1, the upper ends of the fixed rods 2 are connected with a mounting plate 3, and the lower part of the mounting plate 3 is provided with a set of guide sleeves 4 The cover plate 5 and the guide plate 6 on the fixed rod 2 are provided with an oil cylinder 7 for driving the cover plate 5 to move up and down on the mounting plate 3. Two buffer devices 8 are arranged between the plate 5 and the guide plate 6. The buffer device includes a screw 81 connecting the guide plate, the cover plate and the mounting plate, the screw rod is movably connected with the cover plate, and is fixedly connected with the guide plate and the mounting plate. A spring 82 sleeved on the screw rod is provided between the mounting plate and the cover plate, so that a safe distance can be kept between the cover plate and the mounting plate, and a stop nut 83 is...

Embodiment 2

[0034] Example 2, such as figure 1 , Figure 10 and Figure 11 , the above is to provide a way to clamp the condenser, now provide a way to compress the condenser, place the condenser on the frame and stick it to the rear baffle, turn the shaft to make the limit block press the condenser , the other end of the tailgate is provided with a pressing device 17 for pressing the limit block. The pressing device includes a connecting plate 171 vertically connected to the tailgate, and an upper slide is arranged on the connecting plate 171. Groove 176 and down groove 177, and upper chute and down chute are respectively provided with upper pressing plate 172 and lower pressing plate 173 parallel to tailgate, can realize compressing limit block 165 by upper pressing plate and lower pressing plate, described A gap is provided between the upper pressing plate and the lower pressing plate, a movable slide block 174 is provided in the gap, a pressing block 175 located in the gap is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com