A kind of preparation method of grid-like microporous membrane formed by polymer cross-linking

A grid-like, high-molecular technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of undiscovered, slow-controlled release of membrane materials, etc., to achieve uniform distribution and concentrated distribution of micropores , the effect of a large number of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

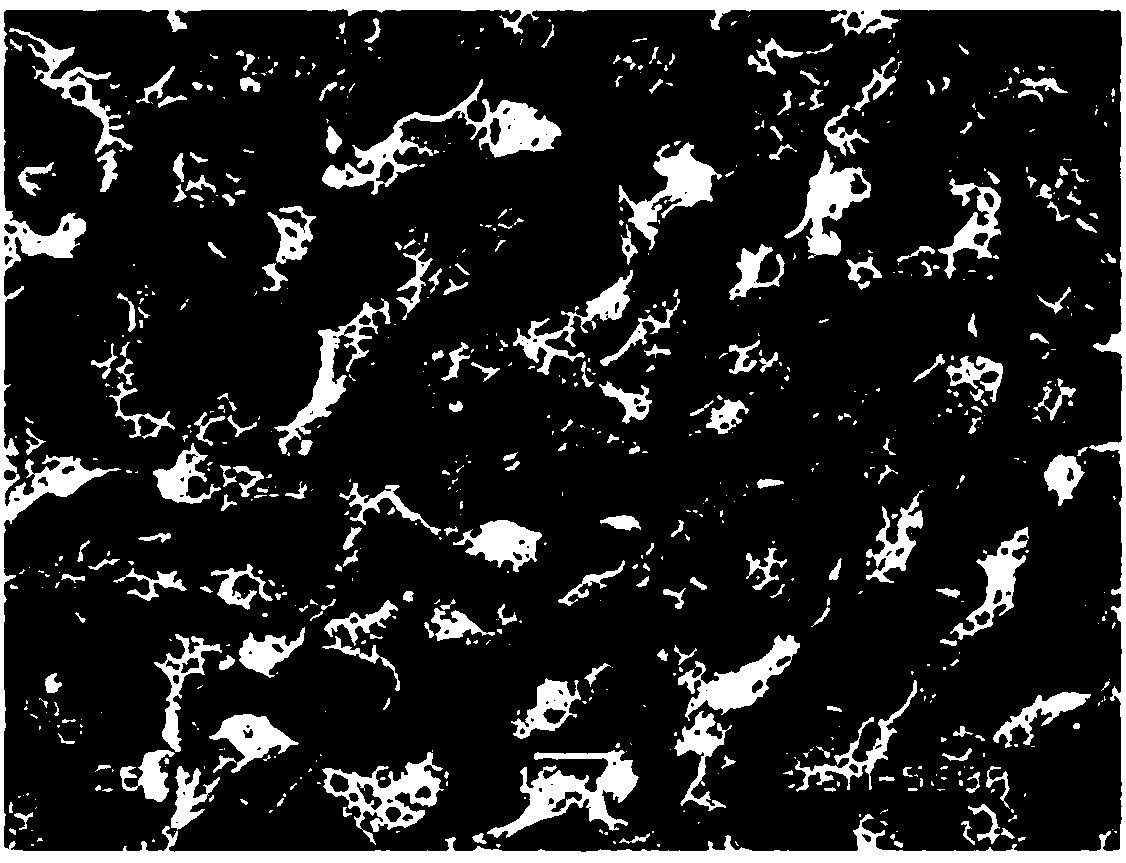

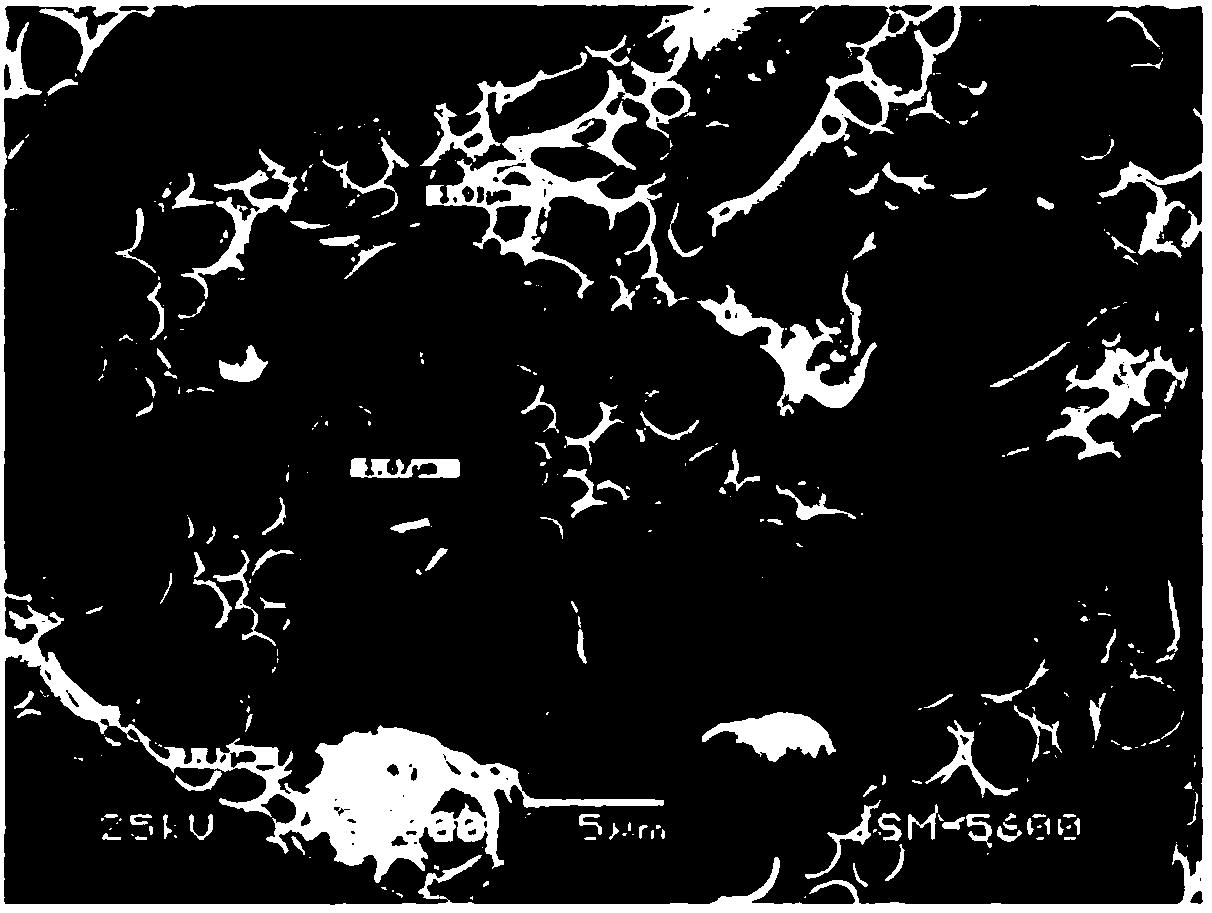

Image

Examples

Embodiment 1

[0015] Example 1 A method for preparing a mesh-like microporous membrane formed by polymer crosslinking, the steps and conditions are as follows:

[0016] (1) The ratio of solvent (mL), film forming agent (g), toughening agent (g) and crosslinking agent (mL) is 100:1:12.5:3, and the mass and volume of the corresponding material are: solvent 20 mL of dimethyl sulfoxide, 0.20 g of polyvinyl alcohol, 2.5 g of thermoplastic polyurethane elastomer as the toughening agent, and 0.6 mL of formaldehyde solution with a mass concentration of 40% as the crosslinking agent;

[0017] (2) According to the proportion, first add the film-forming agent polyvinyl alcohol into a 100mL three-necked flask, add the solvent dimethyl sulfoxide, reflux at 40°C until completely dissolved, add thermoplastic polyurethane elastomer, reflux at 65°C until completely dissolved, and add formaldehyde The solution was refluxed for 30 minutes to obtain a uniform casting solution;

[0018] (3) Cool down the unifo...

Embodiment 2

[0029] Example 2 A preparation method of a grid-shaped high-strength microporous membrane formed by polymer crosslinking, the steps and conditions are as follows:

[0030] (1) The ratio of solvent (mL), film forming agent (g), toughening agent (g) and crosslinking agent (mL) is 100:0.75:10:2.5, and the mass and volume of the corresponding material are: solvent 20 mL of dimethyl sulfoxide, 0.15 g of polyvinyl alcohol, 2.0 g of thermoplastic polyurethane elastomer as the toughening agent, and 0.5 mL of formaldehyde solution with a mass concentration of 40% as the crosslinking agent;

[0031] (2) According to the proportion, first add the film-forming agent polyvinyl alcohol into a 100mL three-necked flask, add the solvent dimethyl sulfoxide, reflux at 40°C until completely dissolved, add thermoplastic polyurethane elastomer, reflux at 65°C until completely dissolved, and add formaldehyde The solution was refluxed for 30 minutes to obtain a uniform casting solution;

[0032] (3)...

Embodiment 3

[0034] Example 3 A method for preparing a mesh-like microporous membrane formed by polymer crosslinking, the steps and conditions are as follows:

[0035] (1) The ratio of solvent (mL), film forming agent (g), toughening agent (g) and crosslinking agent (mL) is 100:1.25:14:3.5, and the mass and volume of the corresponding material are: solvent 20 mL of dimethyl sulfoxide, 0.25 g of polyvinyl alcohol, 2.8 g of thermoplastic polyurethane elastomer as the toughening agent, and 0.7 mL of formaldehyde solution with a mass concentration of 40% as the crosslinking agent;

[0036](2) According to the proportion, first add the film-forming agent polyvinyl alcohol into a 100mL three-necked flask, add the solvent dimethyl sulfoxide, reflux at 40°C until completely dissolved, add thermoplastic polyurethane elastomer, reflux at 65°C until completely dissolved, and add formaldehyde The solution was refluxed for 30 minutes to obtain a uniform casting solution;

[0037] (3) Cool down the uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com