Turbulent agglomeration chamber and method for removing ultrafine particles using the agglomeration chamber

A turbulent and particle technology, applied in the field of turbulent agglomeration chamber, can solve the problems of increasing the complexity of the device, poor utilization of the vortex wake, and increasing the investment cost, and achieves the effect of simple shape, obvious diversion effect, and prevention of wall surface aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

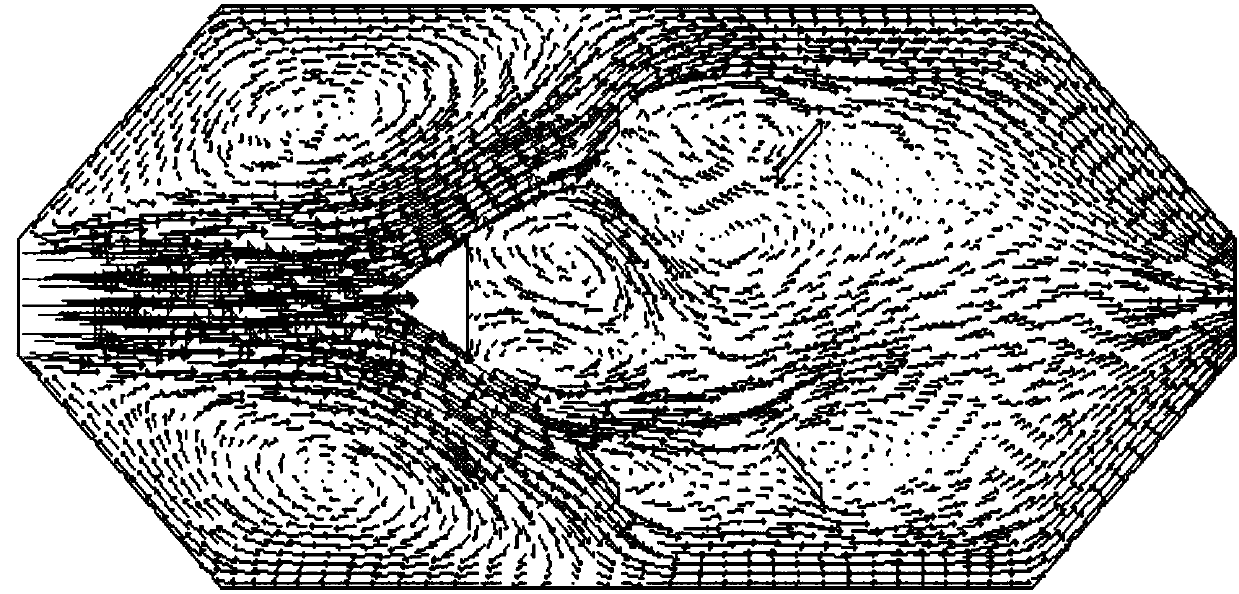

Embodiment 1

[0039] In this embodiment, the flue gas from the turbulent agglomeration chamber is an axisymmetric hexagonal structure, the entrance is in a sudden expansion shape, and the exit is in a zoom shape. The included angle of the center line of the incoming smoke is 45°. Triangular prism spoiler columns 3 and four vortex sheets 2 are arranged inside the reunion chamber. Every two vortex sheets form a group, and the incoming smoke is arranged axisymmetrically. The included angle between the vortex sheet 2 and the center line of the incoming smoke is 45°, and the shortest distance between the vortex sheet 2 and the wall of the reunion chamber is 0.18 of the total width of the reunion chamber; the front view shape of the triangular prism spoiler column 3 is equal to The base of the isosceles triangle is perpendicular to the center line of the incoming smoke, the apex of the isosceles triangle faces the entrance and is located on the center line of the incoming smoke, and the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com