Bubbly plastic heat-preservation shed film

A technology of shed film and plastic, which is applied in the field of daylighting and heat preservation of shed film in solar greenhouses, and can solve the problem of no heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

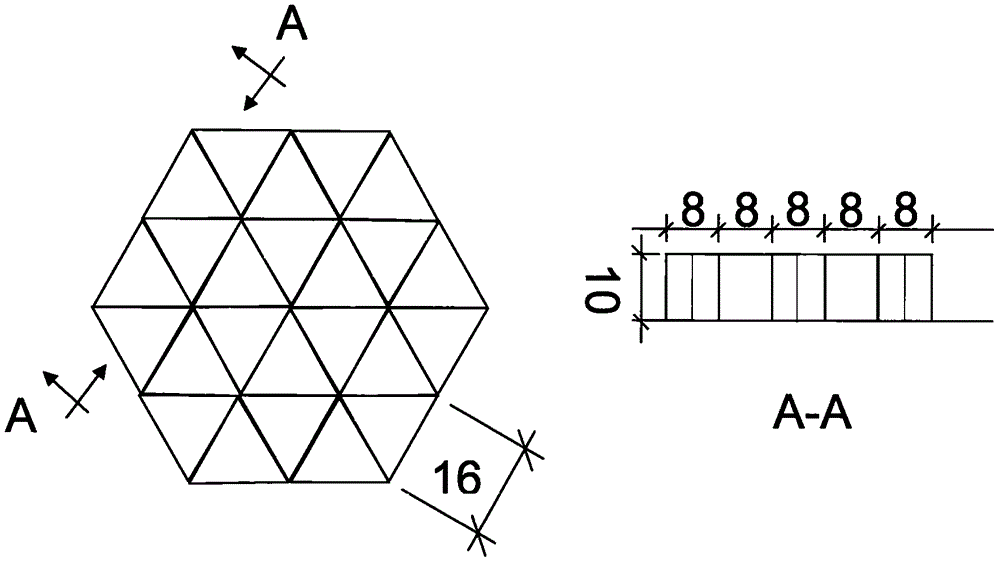

[0011] 1. The method of sticking and pressing a layer of bubbles on one side of the shed film is to stick and press a layer of bubbles on the side of the shed film (outside the greenhouse) based on the existing film technology. figure 1 Plastic air bubbles of the shape and size shown, the material selection of plastic air bubbles is mainly based on high light transmittance, and its thickness is preferably one-tenth of the thickness of the greenhouse film.

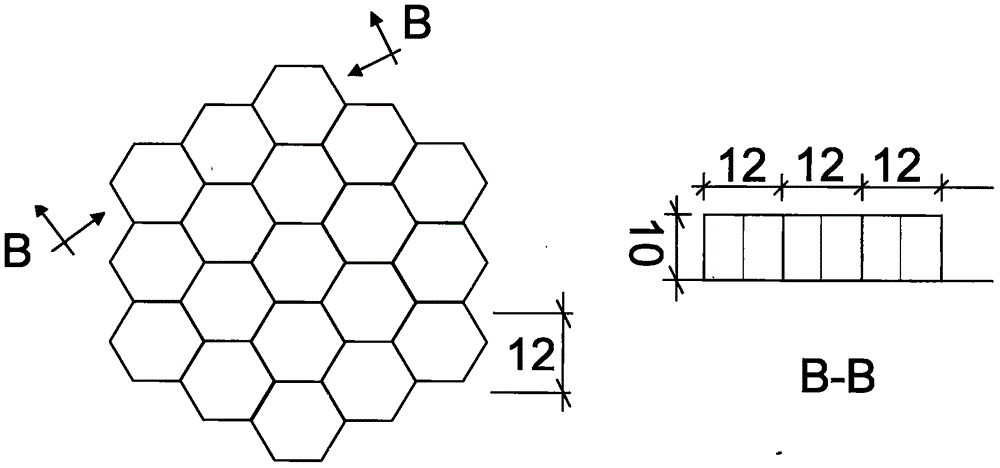

[0012] 2. The method of sticking and pressing a layer of bubbles on both sides of the shed film is as follows: figure 2 The shape and size shown, the material requirements of the bubble are also the same as the existing film technology; the method of a layer of bubbles outside the film (greenhouse) is as follows figure 1 The shape and size shown, the material of the bubble and the material of the shed film itself are mainly based on high mechanical strength and high light transmittance. One is suitable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com