Handle-type high-voltage connector

A high-voltage connector and handle technology, applied in the direction of vehicle connector, connection, two-part connection device, etc., can solve the problems of scrap, easy to break or damage, inconvenient to use, etc., so as to reduce maintenance costs and avoid easily damaged parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the technical content, structural features and achieved technical objectives and technical effects of the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

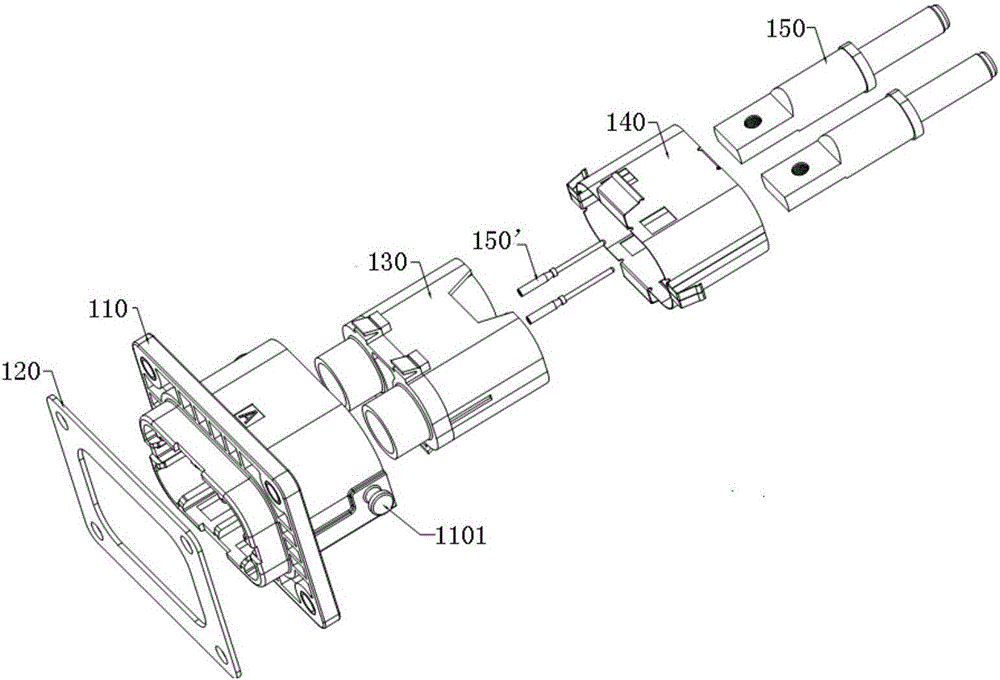

[0028] The handle-type high-voltage connector of the present invention is composed of a high-voltage socket 100 and a high-voltage plug 200 . First, if figure 1 As shown, the high-voltage socket 100 includes: a socket shell 110, a waterproof ring 120, a socket rubber core assembly 130, a socket shield 140, and power pins 150 and signal pins 150'. The socket rubber assembly 130 is located in the socket housing 110, the socket shielding cover 140 is arranged between the socket rubber assembly 130 and the socket housing 110, and the socket shielding cover 140 fully covers the socket rubber assembly 130; There are two through holes, and the two power pins 150 are inserted into the two through holes of the socket rubber core assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com