Backlight driving device and display equipment

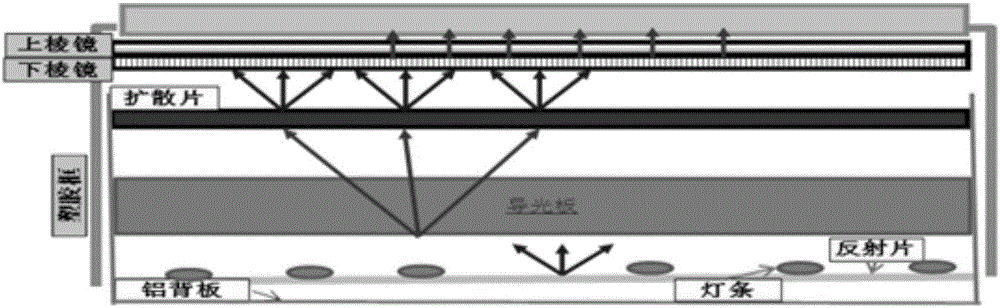

A driving device and backlight technology, applied in static indicators, instruments, etc., can solve the problems of complex process and structure of the backlight driving device, complex light guide plate manufacturing process, complex module device, etc., to save consumables and simplify optics. Structure, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

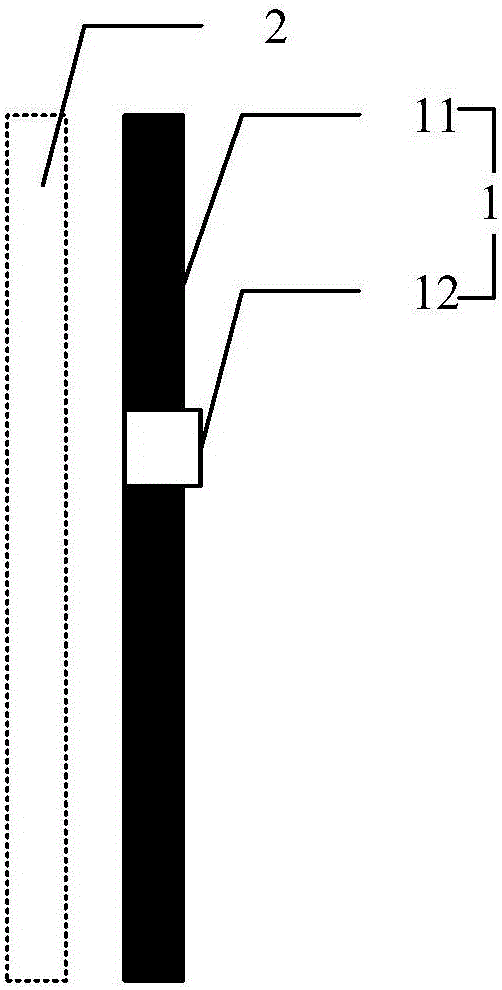

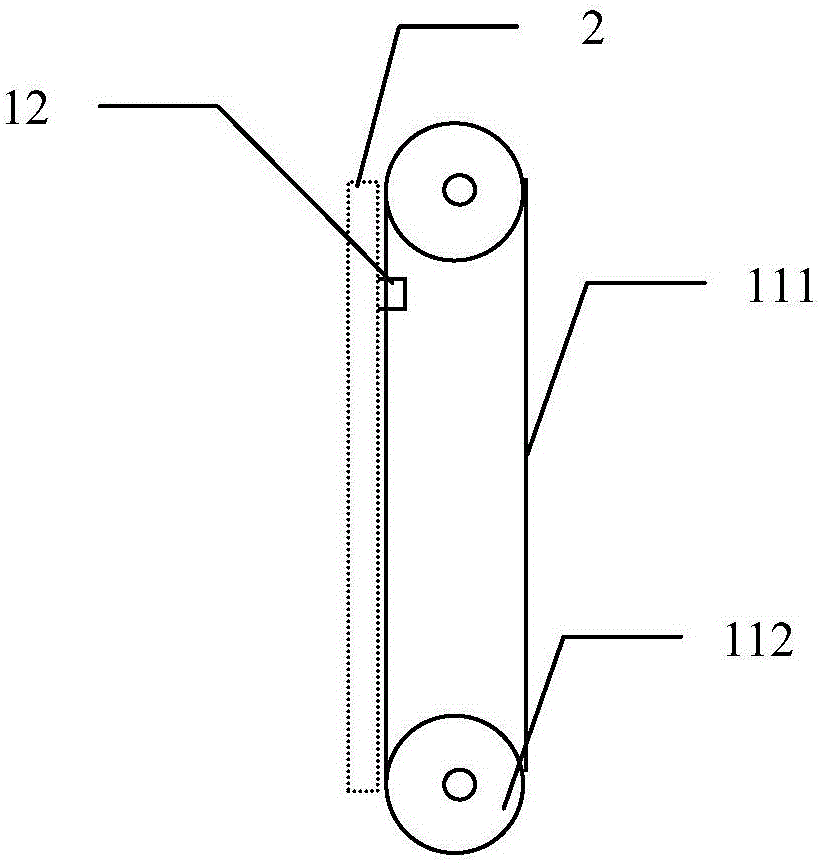

[0032] The backlight driving device of the present application is located on the back of the first liquid crystal display screen, and the transmission unit is used to drive the first LED light-emitting unit installed thereon to perform periodic circular motion along the horizontal length or vertical width of the first liquid crystal display screen, thereby providing The first liquid crystal display provides a backlight. Therefore, the present application adopts the transmission unit and the first LED light-emitting unit to simplify the optical structure of the backlight driving device, simplify the manufacturing process and structural design, save consumables, and are easy to use.

[0033] Of course, implementing any technical solution of the present application does not necessarily need to achieve all the above advantages at the same time.

[0034] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com