Continuous change type integral piston ring mechanical loading device

A mechanical loading device, the technology of loading device, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of contact between the piston ring and the cylinder liner, and achieve the effect of ensuring elastic contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

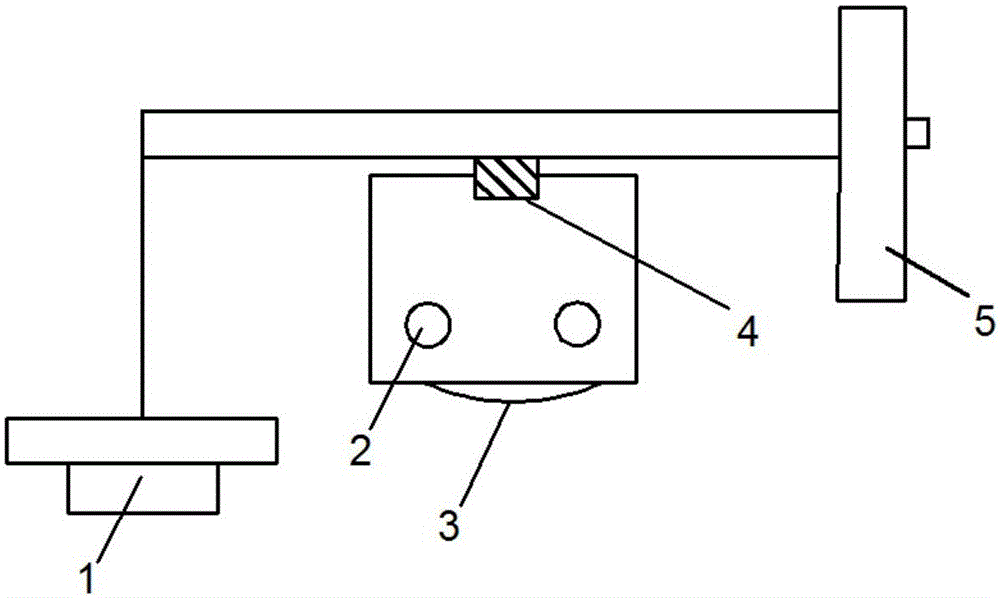

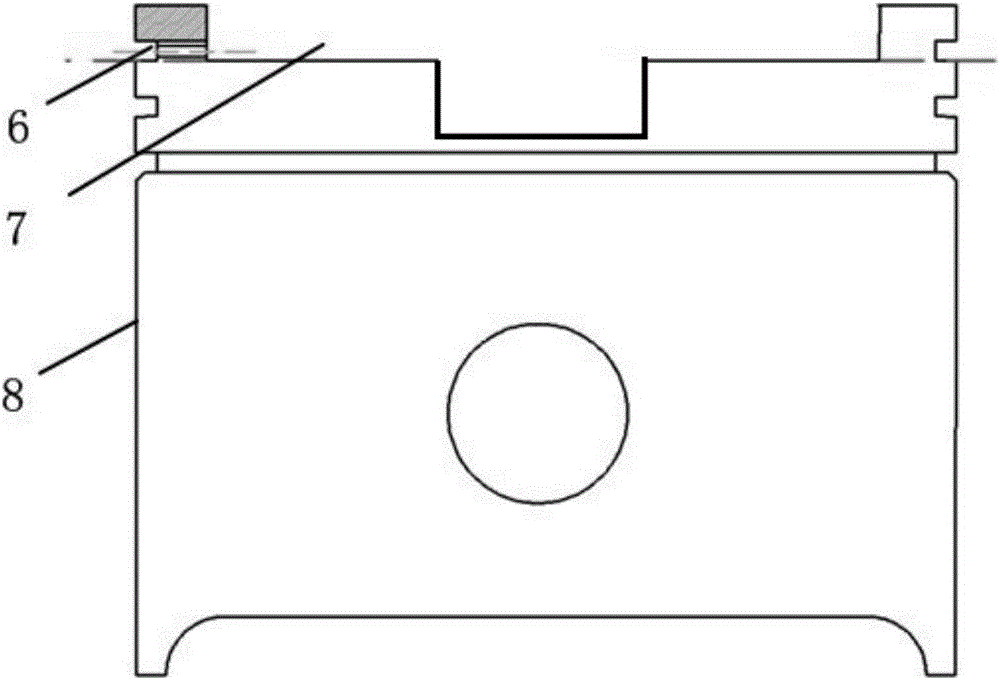

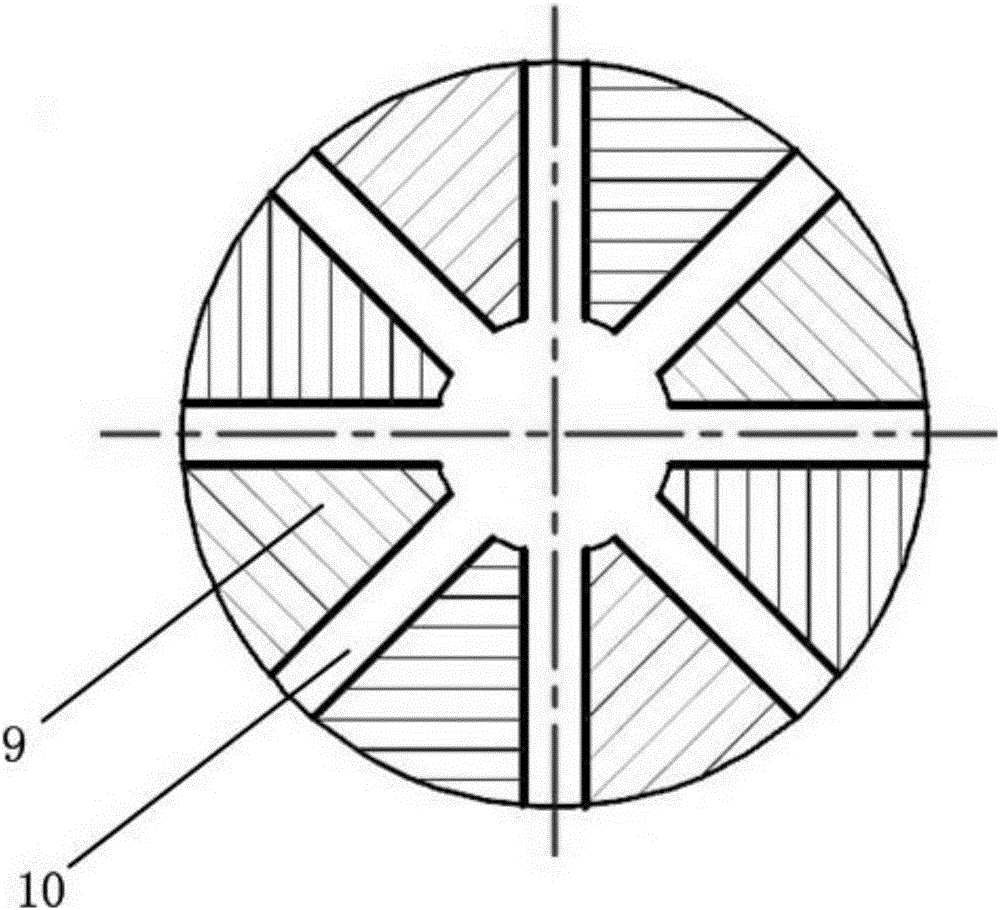

[0016] to combine Figure 1-3 , the piston 8 is the main part of the fixed piston ring and the piston ring loading device, and the piston loading device housing 9 is fixed in the loading device placement groove 7. On the piston loading device housing 9 there are 8 spring assembly placement holes 10 evenly distributed at 45 degrees in the radial direction.

[0017] to combine image 3 , the piston ring 12 is assembled between the cylinder liner 11 and the piston ring groove 6, and the push rod 14 runs through the through hole between the piston ring groove 6 and the loading device placement groove 7. The left end of the push rod 14 is in contact with the piston ring for applying load to the piston ring 12, and the other end is connected with the left spring clamp 15. The spring 16 is located between the spring clamps 15 at the left and right ends, and the right e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com