Continuously variable transmission device capable of automatically adjusting motion state and method of use thereof

A technology of stepless speed change device and motion state, applied in the direction of transmission device, transmission element, element with teeth, etc., can solve the problems of difficult processing, low switching efficiency, high cost, etc., and achieves convenient use, wide application range, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

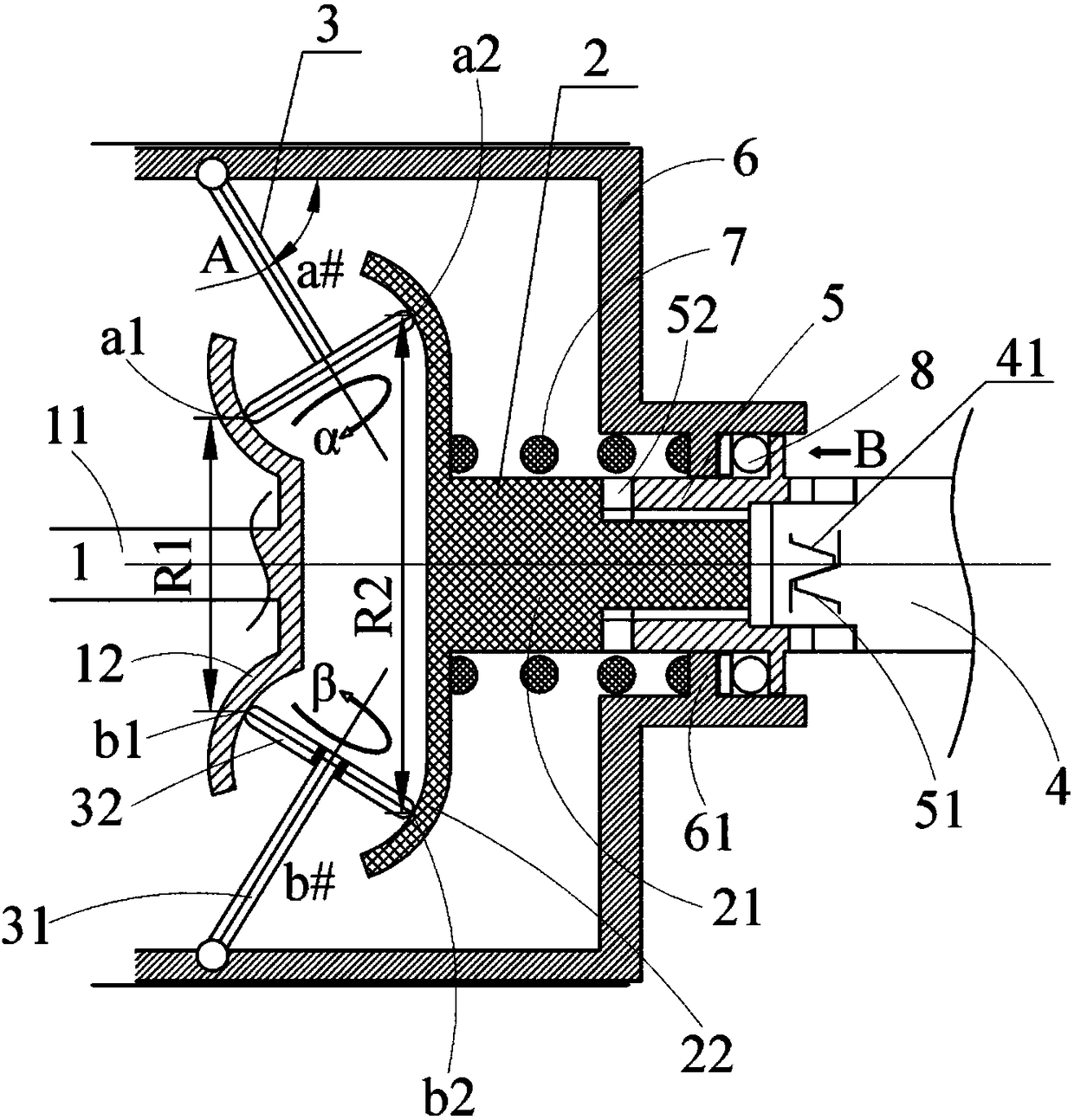

[0021] A continuously variable transmission device that can automatically adjust the motion state, including a drive shaft 1, a driven shaft 2, a transmission wheel 3 and a bracket 6, such as figure 1 As shown, the specific structure is:

[0022] The central axes of the drive shaft 1 and the driven shaft 2 coincide with each other; the drive shaft 1 includes a drive shaft body 11 and a drive transmission surface 12, and the front end of the drive shaft body 11 is vertically fixed at the center of the drive transmission surface 12, and the drive shaft The central axes of the body 11 and the driving transmission surface 12 coincide with each other; the driven shaft 2 includes a driven shaft body 21 and a driven transmission surface 22, and the rear end of the driven shaft body 21 is vertically fixed on the bottom of the driven transmission surface 22. At the center, the central axes of the driven shaft body 21 and the driven transmission surface 22 coincide with each other; the ...

Embodiment 2

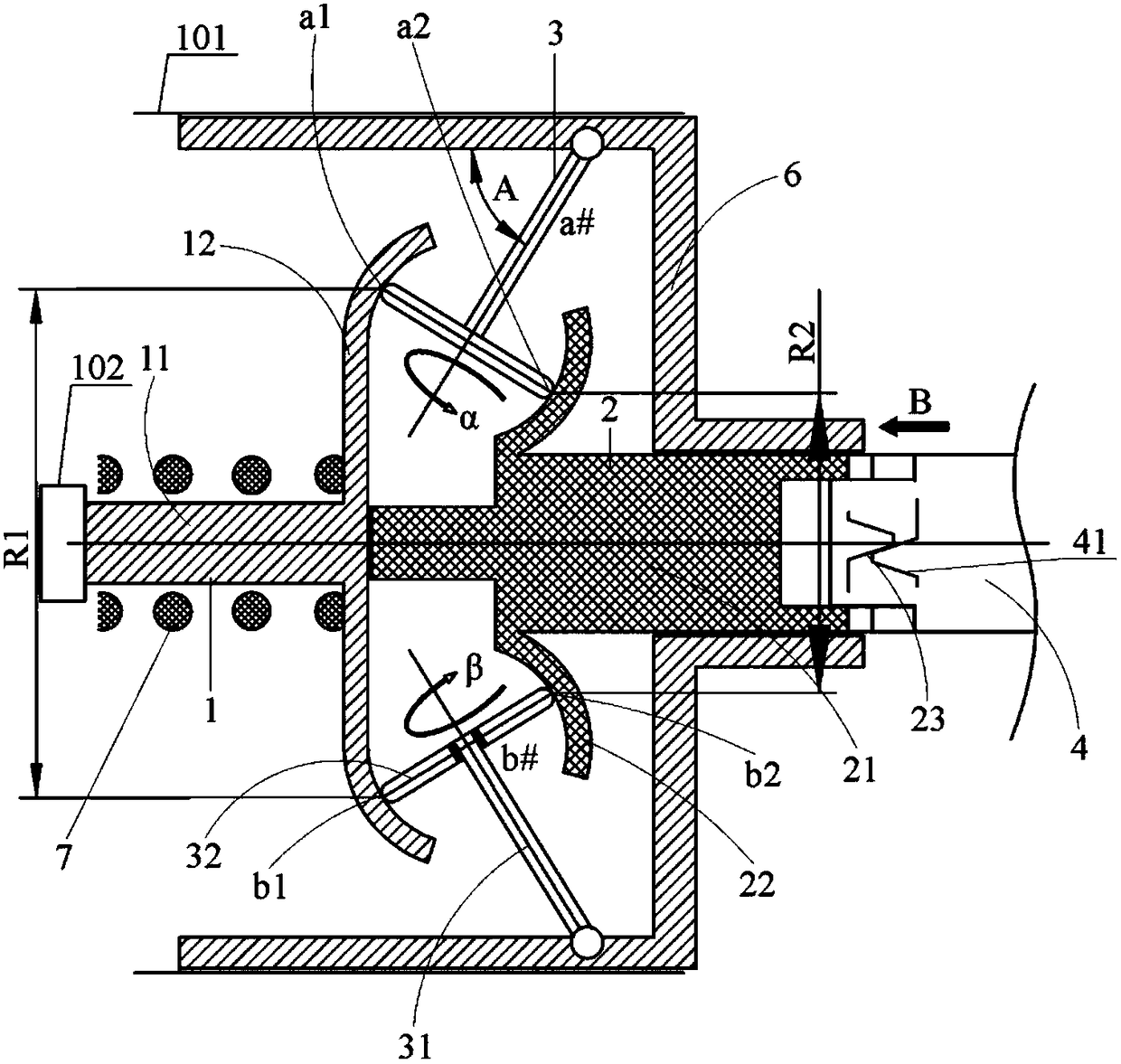

[0034] A continuously variable transmission device that can automatically adjust the motion state, including a drive shaft 1, a driven shaft 2, a transmission wheel 3 and a bracket 6, such as image 3 Shown, concrete structure and embodiment 1 are the same.

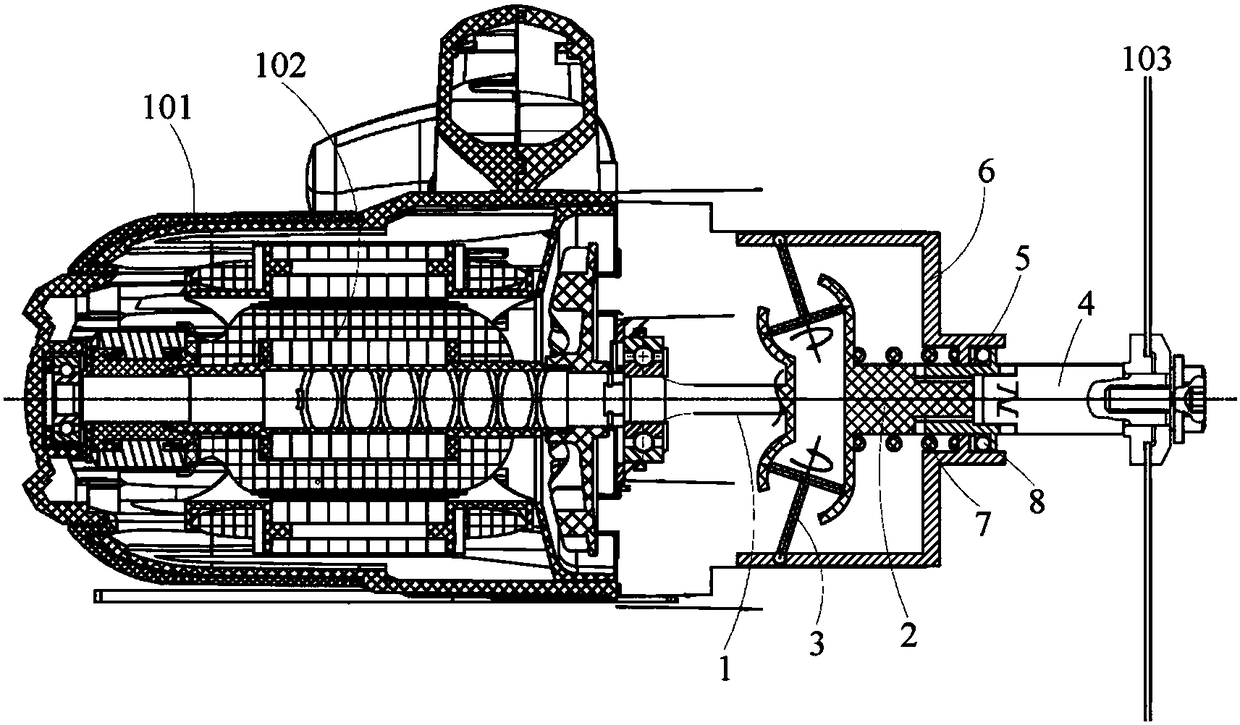

[0035] This embodiment is applied to electric tools, and the electric tools are cutting machines as an example, and can also be used for electric tools such as electric drills, grinders or electric saws, such as image 3 As shown: the electric tool includes a housing 101 and a power system 102 fixed in the housing 101; The connecting surface 41 matched with each other, the front end of the driven shaft 2 engages with the connecting surface 41 through the occlusal surface 23 to connect the output shaft 4; end against the driving transmission surface 12 and the power system 102 respectively; the bracket 6 is located in the housing 101 and can move in the housing 101, the power system 102 outputs torque through the drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com